Table of Contents

Principle of Pin Mill

Pin mill achieves size reduction primarily on the principle of impact, but partly by attrition. The material passes through the clearance of pins attached to the oppositely rotating steel plates. These are a class of high-speed mills.

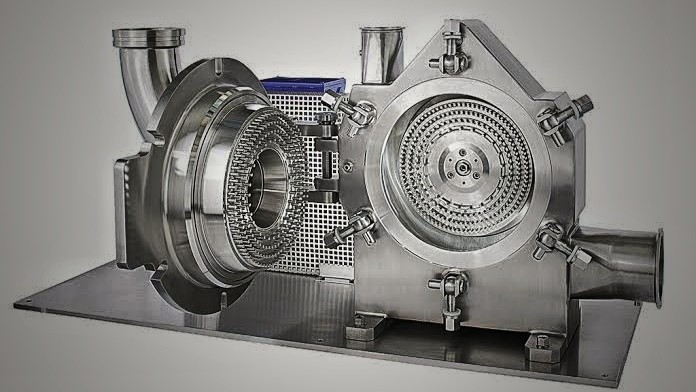

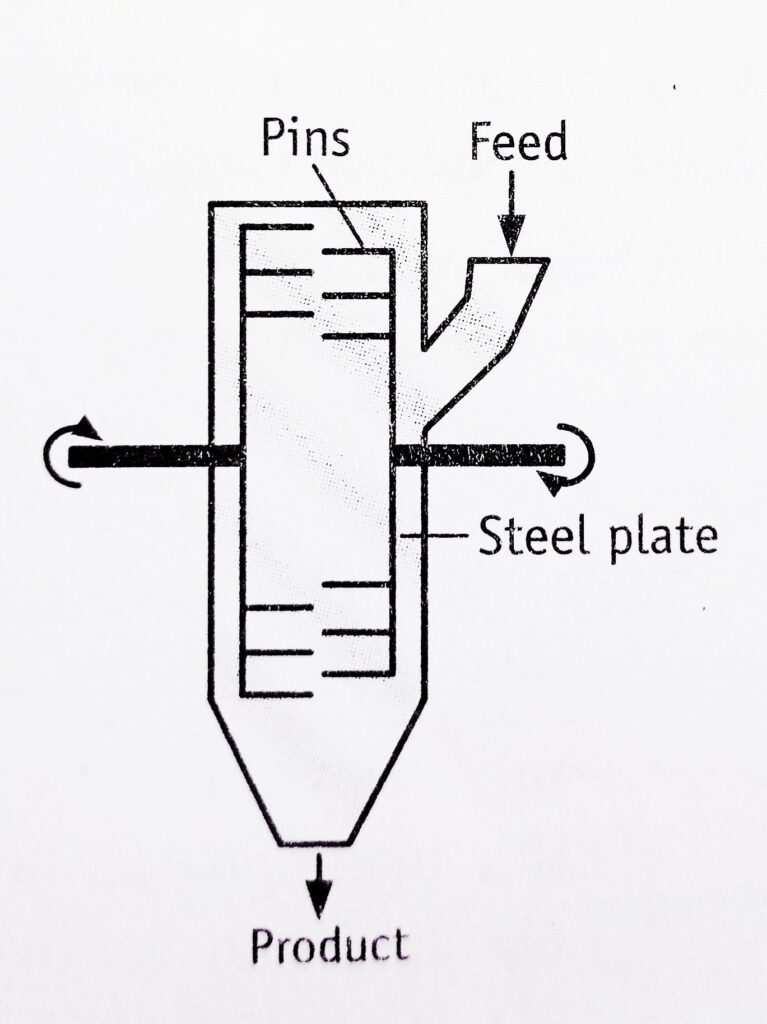

Construction of Pin Mill

The construction of a pin mill is shown in Fig. 1.1. It consists of two vertical steel plates with horizontal projections (pins) arranged in concentric circles on opposing faces. The circles alternate so that the pins pass each other on the rotation. The pins are more closely spaced towards the periphery of the plates. These two plates move in close spaces so that the pins intermesh. This unit is often attached with a vane classifier, which facilitates the return of coarse particles for further size reduction.

Working Pin Mill:

The steel plates are allowed to rotate. The feed material is placed into the hopper, which then flows down to the center of the steel plates. When plates are in continuous motion at high speed, centrifugal action is propelled, so that a large amount of material is thrown towards the periphery. The material passes through the pins The rotating pins beat the material to yield small particles. Size reduction is provided by impact and attrition mechanisms. The milling is more at the periphery because pins are close to each other. From the periphery, the material flows to a separator, so that any grade of fineness can be achieved. The coarse particles return to the mill for further size reduction.

Uses: Damp solids, as well as dry solids, can be handled using the pin mill. Oily materials (full-fat cooked soya meal), soft and non-abrasive materials can be size reduced.

Advantages:

Screens and gratings are absent, thereby clog-free action is achieved. Low milling temperature permits the size reduction of heat-sensitive material. The fineness of grinding can be varied by the use of discs with different dispositions of pins. These mills are available at different capacities, 20 to 4000 kg/hr, and at the fineness from 2.0 um to 2.0 mm.

Variants: Horizontal rotating pins type mill is available and also works at high speeds, however, the principle remains the same. An example is a Mikro-ACM pulverizer. Killoplex mill is another variant.

Make sure you also check our other amazing Article on : Colloid Mill