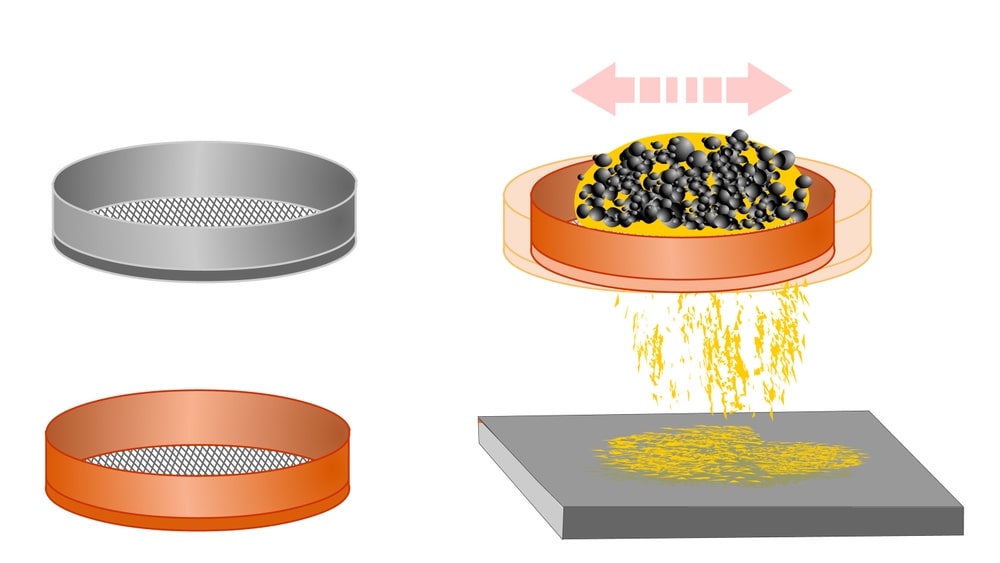

Screening is a method of separating particles according to size alone. The basic technique involved is passing the particles through a series of sieves of uniform size. In this, the particles drop through the openings due to gravity. Coarse particles can drop easily through large openings, but it is difficult to screen the fine powders. This process can be hastened by inducing some type (mode) of motion (movement) in the particles. Size separation is basically assisted by three methods. The Method of Size Separation

- Agitation

- Brushing

- Centrifugal force.

These are the method of size separation of shaking help to shake the material so that sieving will be quick and the entire sieving area can be utilized.

Agitation Method

Sieves are agitated in a number of ways. Some of them are discussed below.

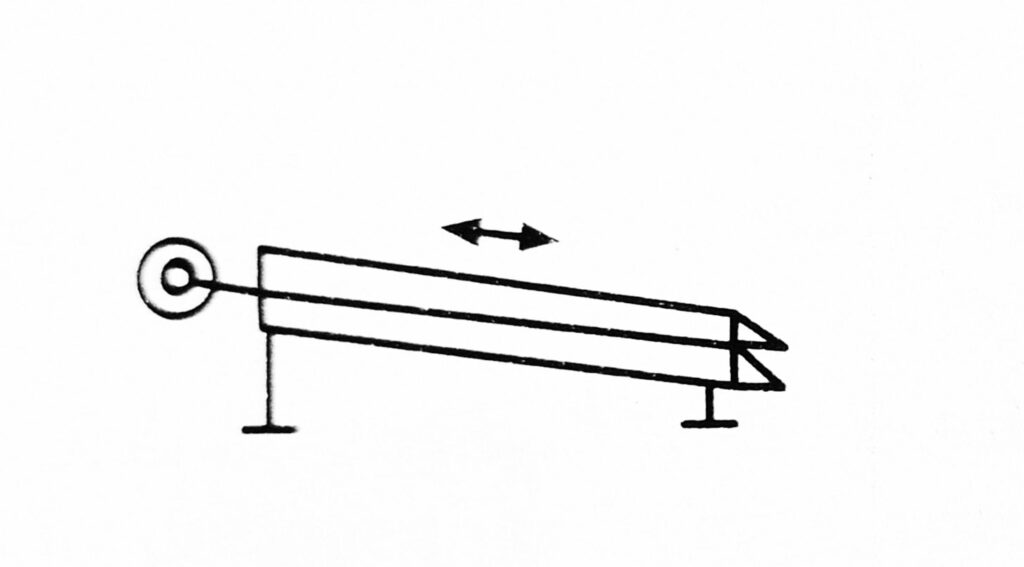

Oscillation: The sieve is mounted in a frame that oscillates back and forth, i.e., reciprocal motion (Figure 1.1). It is a simple method, but the material may roll on the surface of the sieve. The motion is parallel to the plane of the sieve. The sieves can be slightly inclined. The reciprocating motion is induced by means of an ordinary eccentric on a rotating shaft.

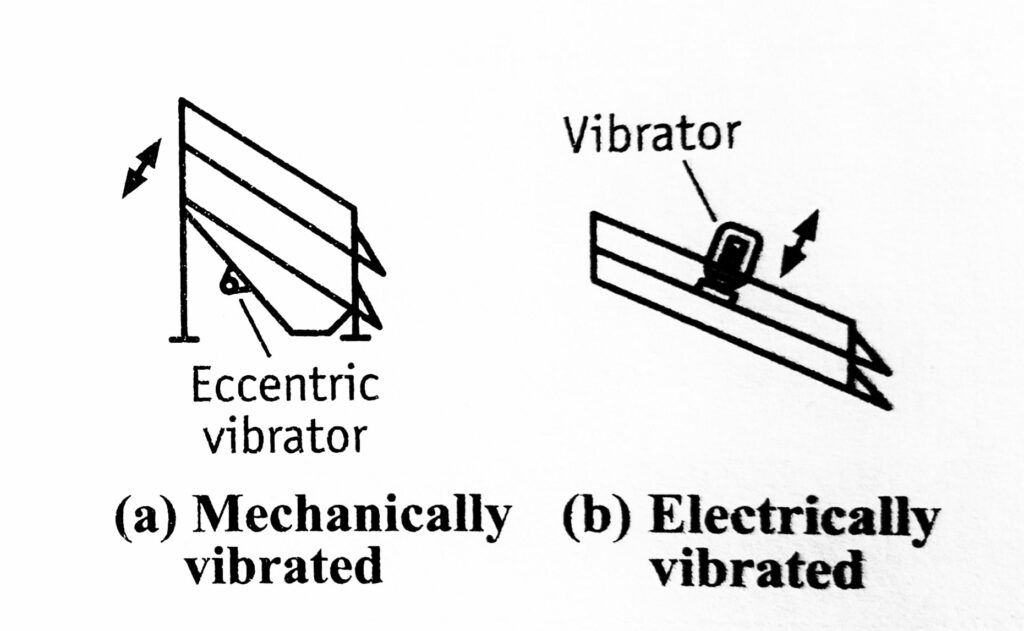

Vibration: The sieve is vibrated at high speed by means of an eccentric device (Figure 1.2) either electrically or mechanically. Rapid vibration is imparted to the particles that help the powder to pass through the sieve. Electrically vibrated screens are particularly useful in the chemical industry. An example is the hummer screen. They handle light, fine, and dry materials successfully. Inducing vibrations also prevents the blinding of meshes.

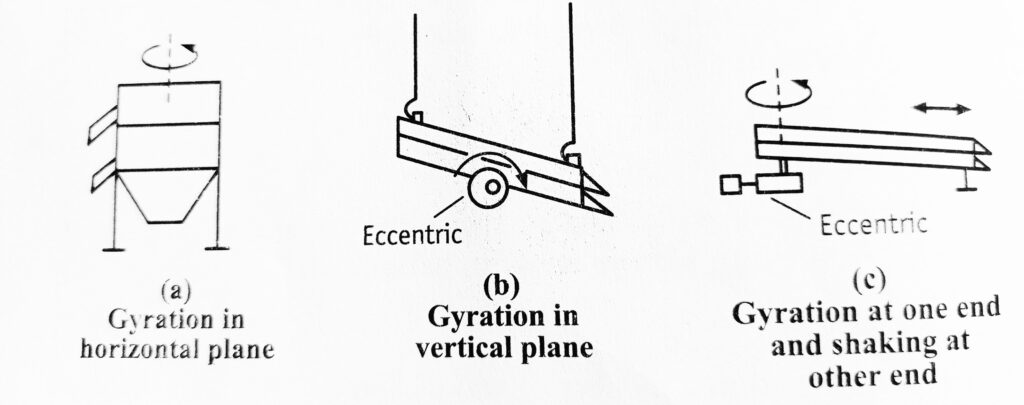

Gyration: In this method, a system is made so that sieve is on rubber mounting and connected to an eccentric flywheel (Figure 1.3). This gives a rotary movement of small amplitude to the sieve, which in turn gives spinning motion to the particles that helps to pass them through the sieve.

Gyratory screens are box-like equipment, either round or square, with a series of screen cloths nested atop one another (Figure 1.3). Most gyratory screens have auxiliary vibrations caused by balls bouncing against the lower surface of the screen. Agitation methods are not continuous methods. However, these can be made continuous by the inclination of the sieves. Separate outlets are made for undersize and oversize particles. Normally, all three modes of agitation are used simultaneously for efficient size separation. Rotex screen works on this principle.

Advantages of Agitation Method

- Agitation methods are inexpensive.

- Simple and rapid.

Disadvantages of Agitation Method

- Agitation methods have a lower limit on particle size.

- If the powder is not dried, apertures become clogged with particles leading to improper sieving.

- During agitation, attrition (particles colliding with each other) occurs causing size reduction.

Brushing Method

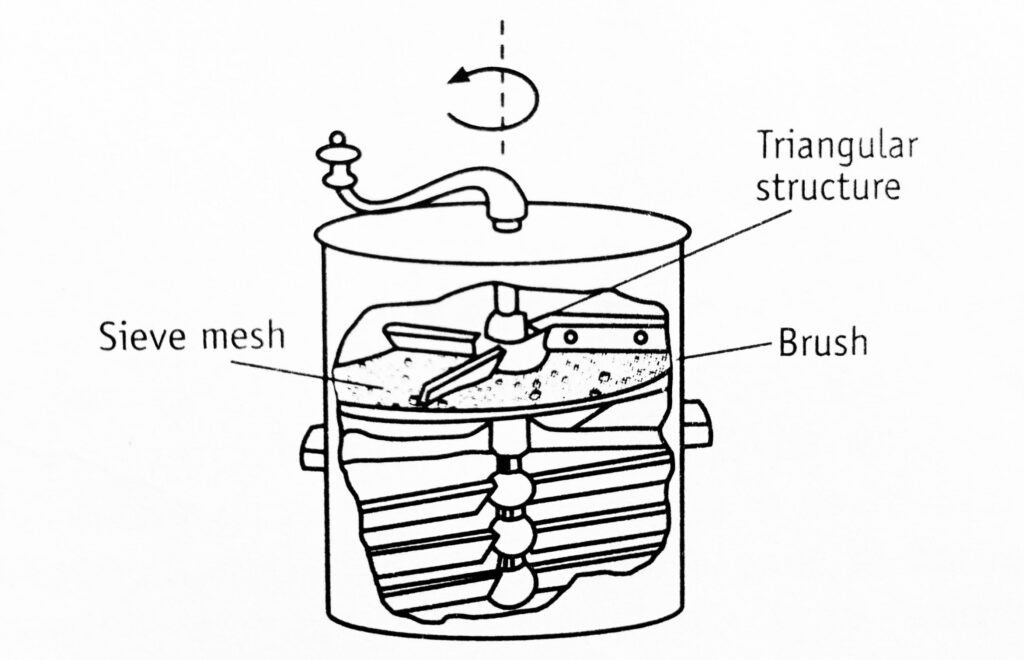

In this case, a brush is used to move the particles on the surface of the sieve and to keep the meshes clear. The brush is rotated in the middle in the case of a circular sieve, but the spiral brush is rotated on the longitudinal axis in the case of the horizontal cylindrical sieve. One example is the brush sifter (Figure 1.4). This is used for size separation of greasy or sticky powders such as waxes and soaps.

Centrifugal Method

In this method, a high-speed rotor is fixed inside a vertical cylindrical sieve, so that on rotation the particles are thrown outwards by centrifugal force. The currents of air can be generated by means of a jet of air into the equipment, which helps in separating the particles. A few examples of equipment that work on this principle are cyclone separators and air separators.

Advantages of Centrifugal Method

- Centrifugal methods are extremely useful in cases where conventional sieving tends to block the sieves.

- Extremely useful for fine powder, because sieves have the limitation of the mesh size.

Make sure you also check our other amazing Article on : Size separation