The basic elements of the screw conveyor are:

- Trough system

- Flights and power supply

- Feeding arrangement

- Discharge arrangement

Table of Contents

Principle

Horizontally or inclined or vertically placed motor-driven screw-like flight conveys the material in the trough from the feed point to the discharge point.

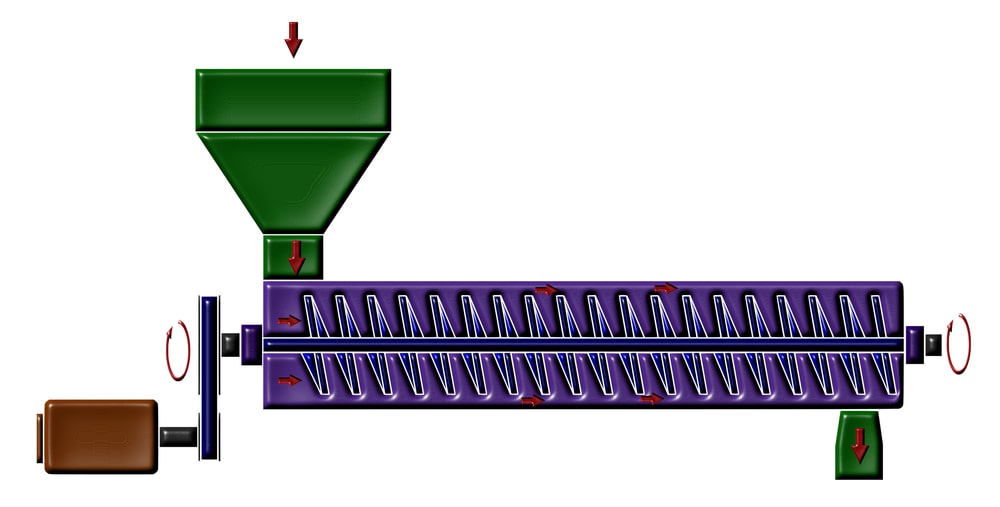

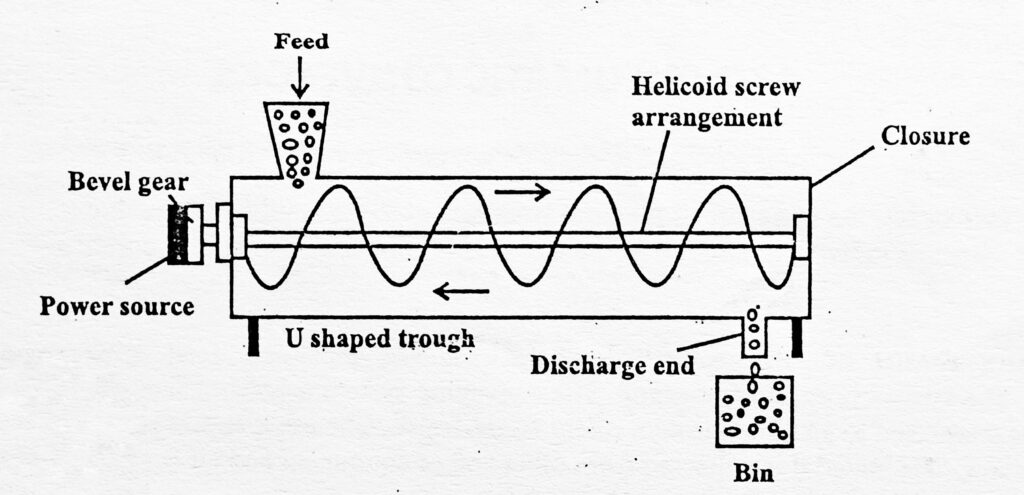

Construction

The trough is a U-shaped vessel in which the material is enclosed during conveying (Figure). The trough is usually made of a sheet of steel and available in standard lengths. If a trough of more length is required, then more number of such units are joined together.

The screw element usually consists of a spiral blade (conveying mechanism is like a screw), which is called flight. The simplest form of flight is the sectional conveyor. Helicoid flight is shown in Figure. It is made of a single long ribbon that is twisted and wrapped into a spiral shape. These standard flights are welded to the central shaft. Alternatively, the conveyor element (helicoid flight element) is suspended with the help of hangers along the length of the trough. Usually, one hanger is used for each flight section. Hangers contain bushings of white cast iron so that lubricants need not be used.

The drive end and discharge end are known as box-ends. At the drive end, shalt is connected to bevel gears. Power is transmitted through the shaft to the flight. The shaft is rotated around an is and remains nearer to the bottom of the trough. The feed is normally introduced by plain spouts, which give the uniform flow of Matera l A at the discharge end, arrangement is made to receive the material using an open-end trough or open-bottom trough.

Working

When power is applied, the drive rotates the shaft through the bevel gear. The screw element starts rotating. The flight is rotated around an axis and remained nearer to the bottom of the trough. Feed is normally introduced by plain spouts. The material will be trapped between the gaps of the spiral blade. As the flight moves, the material also moves forward along the path of the sections. The material is received through an open-end trough or open-bottom trough.

Pharmaceutical Applications

- A screw conveyor is used for transporting finely divided solids or pasty solids.

- Materials having properties such as light-weight, medium-weight, abrasive, non-abrasive, and different densities can be easily handled using a screw conveyor. It is a versatile conveyor system.

- Special flights and casings are available for operations, such as mixing, de-watering, heating, and cooling.

- It has the capacity to handle materials of about 280-meter cubes per hour.

Advantages of Screw Conveyor

- Materials can be conveyed horizontally, vertically, or inclined.

- Screw conveyors are easy to operate and occupy less space.

- Different constructions are available and can be adapted for a variety of materials. Screw conveyors can be fabricated in a variety of materials ranging from cast iron to stainless steel.

- A screw conveyor can be operated at positive and negative pressures.

- High and low temperatures can be maintained by insulating the Casing

- Since it is a closed system, the environment becomes dust-free.

Disadvantages of Screw Conveyor

- Screw conveyors operate at relatively low rotational speeds.

- Extremely cumbersome handling when conveyor becomes larger.

- At high speeds, abrasive problems arise.

- Power consumption per unit weight transferred is high.

Selection of Screw Conveyor

The size and speed of a screw conveyor are determined to make a choice of design. The type of construction depends on the requirements such as:

- Scale of operation

- Severity of service

- Value of the material

Make sure you also check our other amazing Article on : Belt Conveyor