Principle

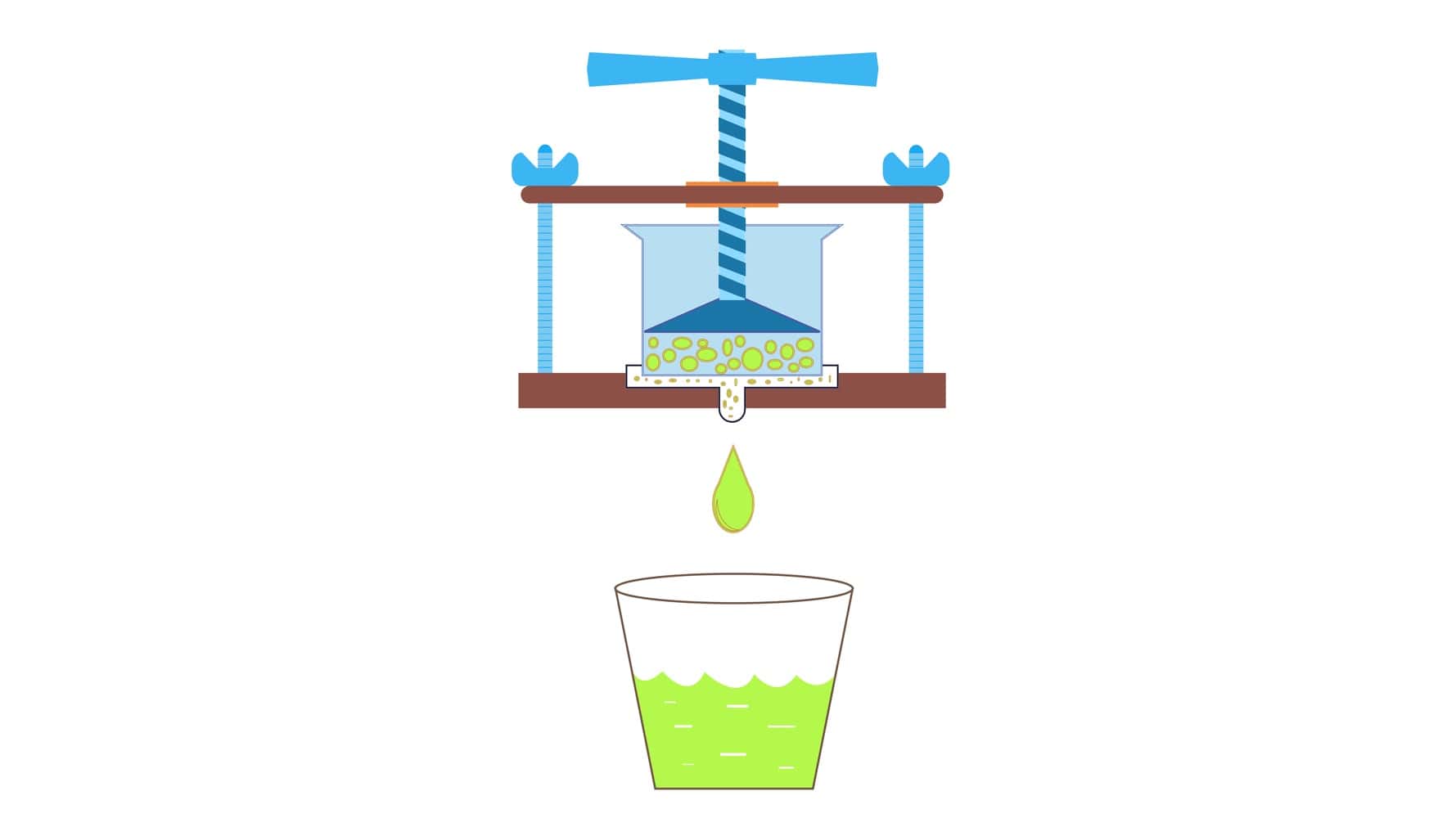

A screw Press is an expeller of oil from solid materials, by pressing the solids at high pressure continuously. When the solid material is introduced through the feed inlet into the screw element, the material moves into the clearance between the rotating screw and stationary barrel and gets pressed. Thus oil is separated continuously.

Construction of Screw Press

The construction of a screw press is shown in Figure. It consists of a barrel containing a stainless steel helical screw. This mechanical press has five elements, main worm shaft, drainage barrel, choke mechanism, motor transmission, thrust bearing, and cooling systems. The screw flight is not straight, but tapered (increases) towards the discharge end. This increases the pressure on the pulp as it is carried through the barrel.

Working

The solid material is introduced through the feed inlet (Figure ). The screw element is allowed to rotate using a suitable power supply. The material is trapped between the gaps (clearance) of the spiral blade and the stationary disc plate. The material gets pressed in the clearance and passes through the outlet. The extracted oil is filtered and collected in a settling tank. The settled solids are sent back to the fresh material feed. The cake contains 8 to 10% oil. The cake is crushed into the coarse meal (material) and solvent extraction is attempted with hexane or heptane in order to further extract the oil.

Advantages: Screw press has an advantage over solvent extraction in being simple and has low investment cost.

Disadvantage: Screw press consumes high power. The wear and tear of machinery are also high, leading to high working costs. During straight pressing, heat is generated resulting from the lowering of quality of the oil and particularly the meal.

Make sure you also check our other amazing Article on : Triple Roller Mill