The dried granules are compressed into a tablet in a machine known as a Tablet compression machine or press

There are different types of presses used for this purpose

- Single Punch Tablet machine

- Multistation rotary press

- Dry cota tablet machine

Table of Contents

Single Punch Tablet machine

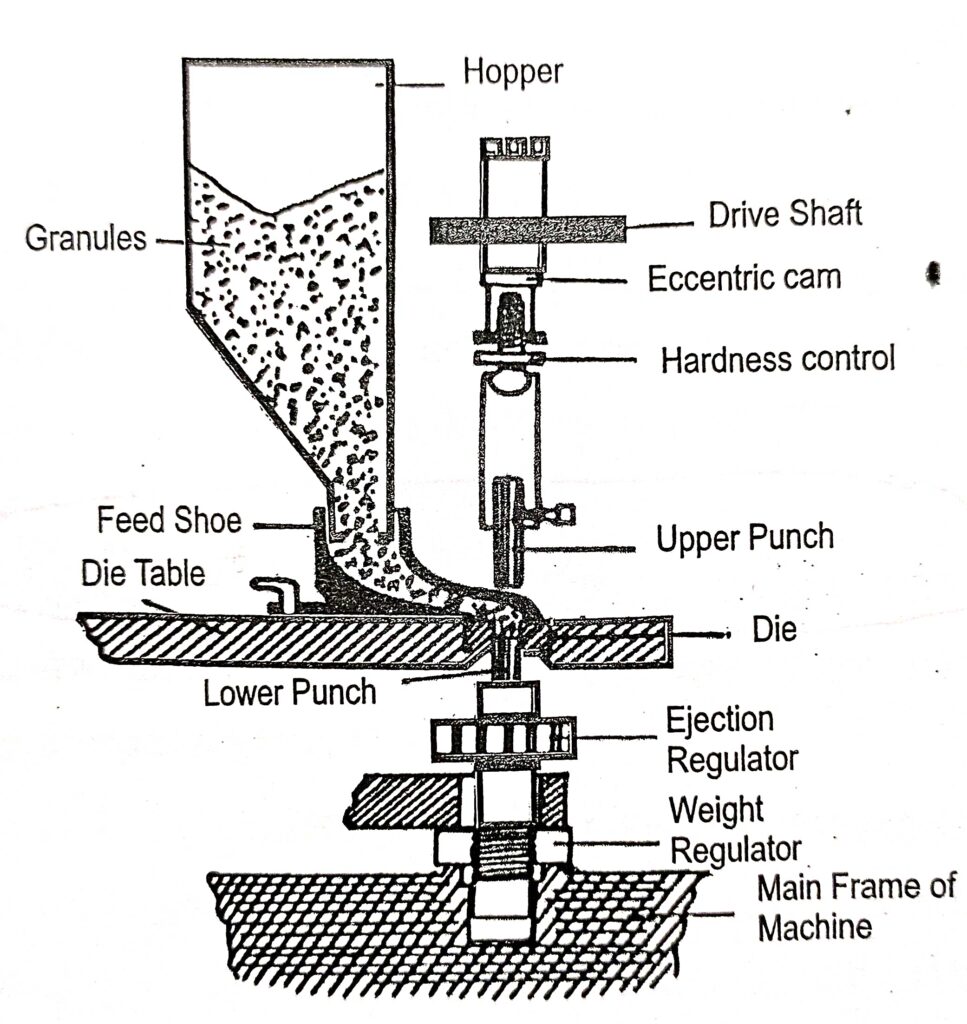

It is also called an eccentric press or single station press. The single punch tablet machines include a die and a pair of upper and lower punches. The functional part of the Single Punch Tablet machine are

- Hopper – It is used to supply granules/ powder mixtures to die prior to compression. The hopper can be filled manually or by using mechanical equipment.

- Die– It permits the lower punch to come close to the upper punch so that compression of granules takes place.

- Die cavity-The die cavity is where the powder granules are compressed into a tablet.

- Punches – This includes upper punch and lower punch. The amount of powder-filled into the die is adjusted by the position of the lower punch. Punches are used to compress the powder into tablets of various shapes within the die.

- Cam track – This helps to guides the position/movement of the punches.

- Capacity regulator – This is used to adjust the lower punch position to allow only the required quantity of granules by the die.

- Ejection regulator – These facilities the ejection of the tablet from the die cavity after compression

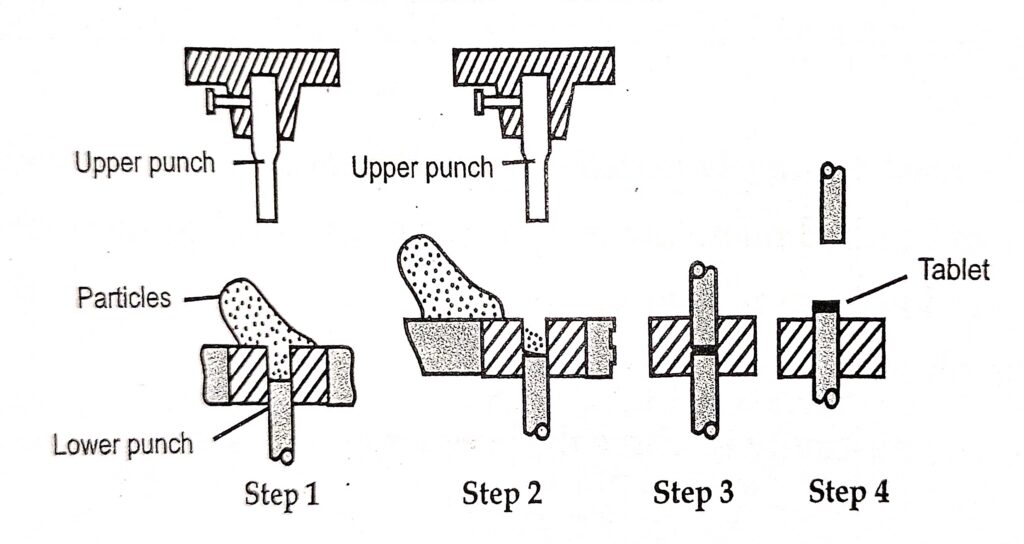

Working of Single Punch Tablet machine

The upper punch moves up and the lower punch moves down to create a cavity in the die. The feed from the hopper falls into the die cavity. The upper punch moves down to compress the granules/powder mixture into tablets. The upper punch moves up and the lower punch also moves upwards to eject the compressed tablet. The whole process repeats again and again

unit the feed material is exhausted. The machine is easy to operate. The output is about 200 tablets per minute. A single punch tablet machine is ideal for small batch production. Single punch tablet press utilizes a high amount of pressure to reduce weight variations between tablets.

Multistation rotary press

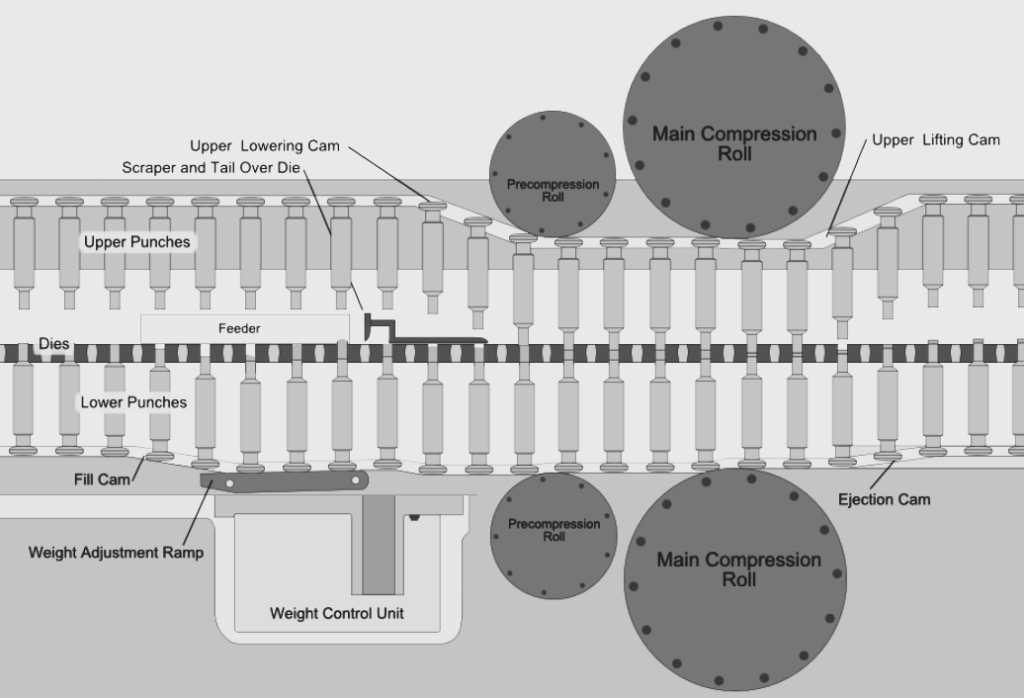

The multi-station press is termed rotary because it comprises approximately 60 sets of dies and punches which rotates to compress granules/powder mixture into tablets of uniform size, shape, and uniform weight. This is used for large-scale production. The machine increases the output of tablets. The machine produces 1200 tablets in one minute.

Parts of Multistation Rotary press

- Upper and Lower Turrets: It is that portion of the head that holds upper and lower punches.

- Lower cam track: It is used to guide the lower punch to ensure the die cavity is overfilled. Feeder or Feed Frame: It is used to feed the powder or granules into the die.

- Cam tracks: It guides the movement of both the upper and lower punches

- Ejection cam: It is used to facilitate the ejection of tablets from the die cavity by moving lower punch upward.

- Take-off blades: It helps to push the tablets to a discharge chute, which is collected in the container.

Working Multistation rotary press:

As the name indicates “rotary tablet press” it has a rotating turret. The powder or granules are placed in the hopper. From where it will flow to the tooling system of the machine ready for compression. The material is then fed into several dies simultaneously. There is an accurate filling of the die cavities. The machine removes excess powder to avoid any form of inconsistencies. Therefore, desired volume and weight of the powder are compressed into tablets. The upper and lower punches exert a predetermined amount of pressure that compresses tablets to the right size and depth.

As the head revolves, the dies come under the feed frame and get filled. These granules get compressed when the upper and lower punches come close together. The pre-compression process removes any traces of air that might be within the powder particles. While the main compressor exerts an appropriate amount of force that compacts powder to a desired thickness and hardness. The pressure is exerted on the punches by a series of pressure rolls.

It is a continuous process. The upper cams pull the upper punches back to their initial position and the lower punches are also lifted up to eject processed tablets out of the die cavity. The scraper will then remove the tablet from the compression machine to the discharge chute. It is considered as the end of one complete cycle of the tablet compression machine

It is a cost-efficient and automated system. It is suitable for continuous operations.

Dry cota tablet machine

This machine is preferred for multi-compressed, multi-colored, and press-coated tablets. In this machine two rotary machines work simultaneously therefore core tablet is prepared in one machine which is then transferred to the second machine for compress coating. It is easy to install, operate and maintain. Draycott allows customers to manufacture a wide variety of tablet shapes.

Make sure you also check our other amazing Article on : Parenteral Formulations