Table of Contents

Principle of the fluidised bed dryer

In fluidised bed dryer, hot air (gas) is passed at high pressure through a perforated bottom of the container containing granules to be dried. The granules are lifted from the bottom and suspended in the stream of air. This condition. I called fluidized state. The hot gas is surrounding every granule to completely dry them. Thus, materials or granules are uniformly dried.

Construction of the fluidised bed dryer

Two types of bed dryers are available, vertical fluid bed dryer and horizontal fluid bed dryer.

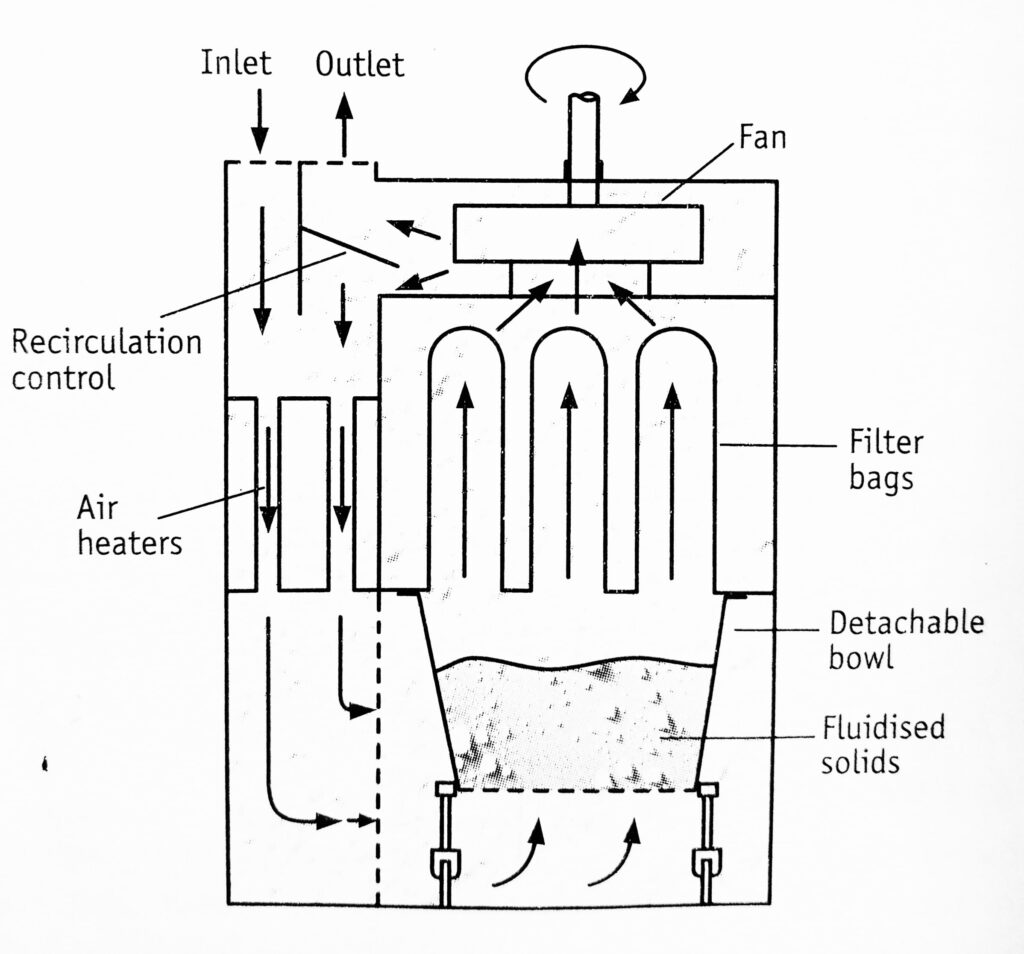

The construction of a vertical fluidised bed dryer is shown in Figure 1.1. The dryer is made up of stainless steel or plastic. A detachable bowl is placed at the bottom of the dryer, which is used for charging and discharging. The bowl has a perforated bottom with a wire mesh support for placing materials to be dried. A fan is mounted in the upper part for circulating hot air. Fresh air inlet, prefilter, and heat exchanger are connected serially to heat the air to the required temperatures. The temperature of hot air and exit air is monitored. Bag filters are placed. above the drying bowl for the recovery of fines.

Working on fluidised bed dryer

The wet granules to be dried are placed in the detachable Bowl. The bowl is pushed into the dryer. Fresh air is allowed to pass through a prefilter, which subsequently gets heated by passing through a heat exchanger. The hot air flows through the bottom of the bowl. Simultaneously fan is allowed to rotate. The air velocity is gradually increased.

When the velocity of the air is greater than the settling velocity of granules, the granules remain partially suspended in the gas stream. After some time, a point of pressure is reached at which frictional drag on the particles is equal to the force of gravity. The granules rise in the container because of high-velocity gas (1.5 to 7.5 meters per minute) and later fall back in a random boiling motion. This condition is said to be fluidised state. The gas surrounds every granule to completely dry them. The air leaves the dryer by passing through the bag filter. The entrained particles remain adhered to the inside surface of the bags. Periodically the bags are shaken to remove the entrained particles.

Intense mixing between granules and hot gas provides uniform conditions of temperature, composition, and particle size distribution. Drying is achieved at a constant rate and the falling rate period is very short. Any attempt to increase the air velocity may result in entrainment.

The residence time for drying is about 40 minutes. The material is left for some time in the dryer for reaching ambient temperature. The bowl is taken out for discharging. The end product is free-flowing.

Uses: Fluidised bed dryer is popularly used for drying granules in the production of tablets. Fluidised bed dryer can be used for three operations such as mixing, granulation, and drying. It is modified for the coating of granules.

Advantages of fluidised bed dryer

- Fluidised bed dryer requires less time to complete drying, i.e., 20 to 40 minutes compared to 24 hours of a tray dryer. Handling time is also short. It is 15 times faster than the tray dryer.

- It is available in different sizes with a drying capacity ranging from 5 to 200 kg per hour.

- The drying containers are mobile, making handling simple and reducing labor costs.

- The thermal efficiency is 2 to 6 times that tray dryer.

- It is also used for mixing the ingredients and its mixing efficiency is also high.

- Hot spots are not observed in the dryer, because of its excellent mixing and drying capacities.

- Higher drying temperatures can be used that are not possible in tray dryers and truck dryers.

- It facilitates the drying of thermolabile substances since the contact time for drying is short.

- It can be used either as a batch type or continuous type.

- It has a high output from a small floor space.

- The free movement of individual particles eliminates the risk of soluble material migrating as may occur in static beds.

Disadvantages of fluidised bed dryer

Many organic powders develop electrostatic charges. during drying. To avoid this, efficient electrical earthing of the dryer is essential. The turbulence of the fluidised state of granules may cause attrition of some materials resulting in the production of fines. But using a suitable binding agent this problem can be solved. Fine particles. may become entrained and must be collected by bag filters.

Variants: Plug flow dryer: It is a rectangular fluid bed dryer having different compartments for fluidization. The material is made to move from the inlet through different compartments to the outlet. Different drying conditions can be maintained in the compartments. Often the last compartment is fluidised with cold gas to cool the solids before discharge.

Make sure you also check our other amazing Article on : Spray Dryer