Principle

In Semi Continuous centrifuge, separation occurs through a perforated wall depending on the difference in the densities of solid and liquid phases.

Construction

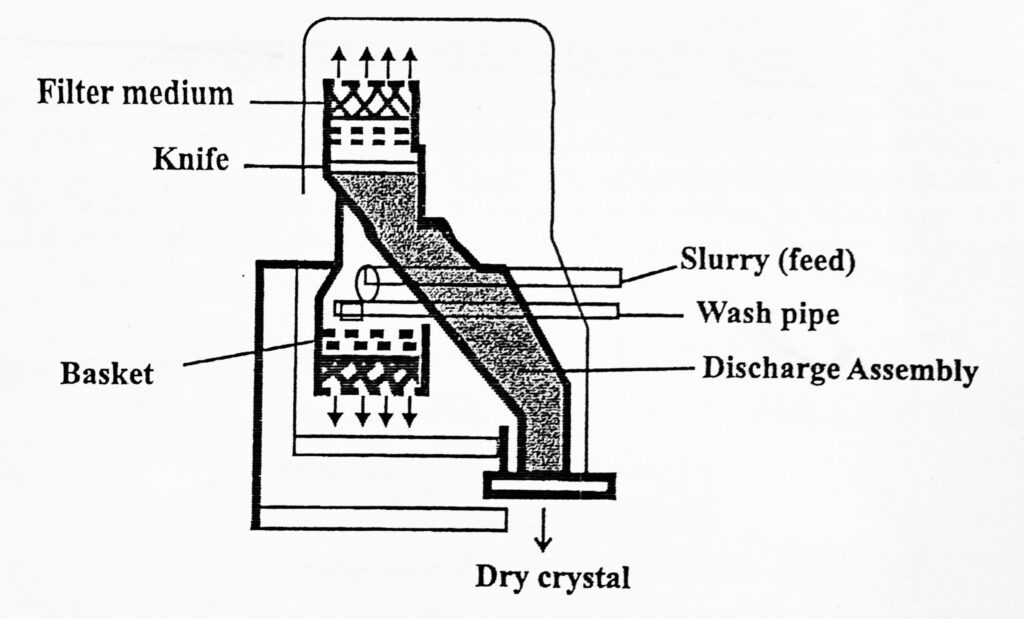

Semi Continuous Centrifuge consists of a perforated basket mounted on a horizontal shaft and run continuously by the motor. The side of the basket is perforated. Feed or suspension is introduced through a feed pipe. There is also the provision of a wish pipe which is used to wash the crystals. The thickness of the feed depends on the feeler which rides over the feed. The layer of cake is removed by a chute fitted with a knife. The knife cuts down the cake within the basket. The knife-chute assembly is raised with the help of a hydraulic apparatus.

Working

The basket is rotated horizontally with a motor. The suspension is introduced through the pipe. The slurry passes through the perforated side. The crystals remain inside the basket. The filtrate is eliminated from the outlet. When the height of the cake is approximately 2-3 inches, the suspension inlet is stopped by a “feeler diaphragm valve assembly”. The basket rotates at a predetermined time and then the cake is washed with water. The basket is rotated for another predetermined time. After that, the hydraulic apparatus raises the knife-chute assembly to cut the cake. The cake is collected through the chute.

Advantages

- This centrifuge is used to separate crystals from the mother liquor.

- This is used to clarify Liquids by removing unwanted solids and dirt from oils.

Disadvantage

- Complicated process

- Sometimes chances of breakage of the crystal during discharge.

- High power consumption

Make sure you also check our other amazing Article on : Super Centrifuge