Principle

In an air separator, centrifugal force is used to separate solids. The air environment is obtained by means of rotating discs and blades. To improve the separation, stationary blades are used. By controlling these blades and the speed of the rotation, it is possible to vary the size at which separation occurs.

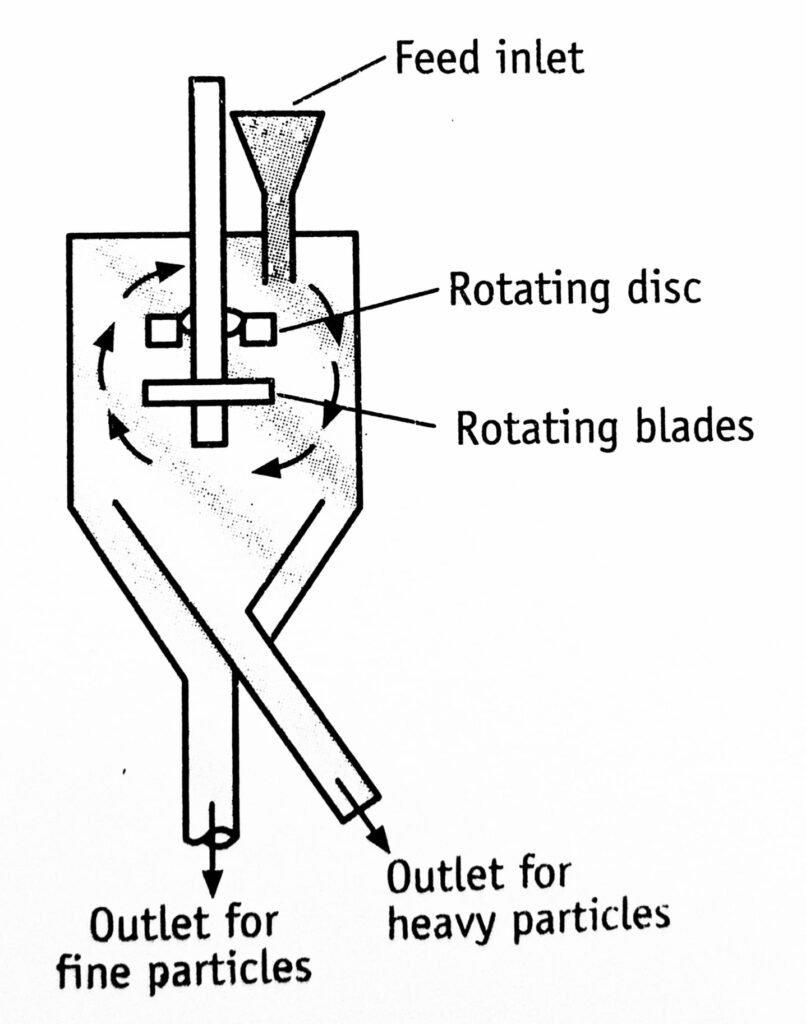

Construction of the Air Separator

The construction of an air separator is shown in Figure 1. It consists of a cylindrical vessel with a conical base. The feed inlet is fitted to the upper part of the vessel. The rotating disc and rotating blades are attached to the central shaft to produce an air environment. At the base of the vessel. two outlets are provided; one for fine particles and the other for heavy particles.

Working

The disc and blades are allowed to rotate by means of a motor. These produce a current of air as shown by the arrows. The sample powder is introduced through the feed inlet. The feed falls on the rotating disc. The fine particles are picked up and carried into space, where air velocity is sufficiently reduced. The fine particles are dropped and are ultimately collected at the outlet meant for the fine particles. The heavy particles, which fall downward, are removed at the outlet meant for heavy particles.

Uses: Air separators are often attached to the ball mill or hammer mill to separate and return oversized particles for further size reduction.

Make sure you also check our other amazing Article on : Planetary Mixer