Table of Contents

Principle

In a bag filter, the size separation of fines (or dust) from the milled powder is achieved in two steps. In the first step, the milled powder is passed through a bag filter (cloth) by applying the suction on the opposite side of the feed entry. This facilitates the separation. In the next step, pressure is applied in order to shake the bags so that powder adhering to the bag falls off, which is collected from the conical base.

Construction

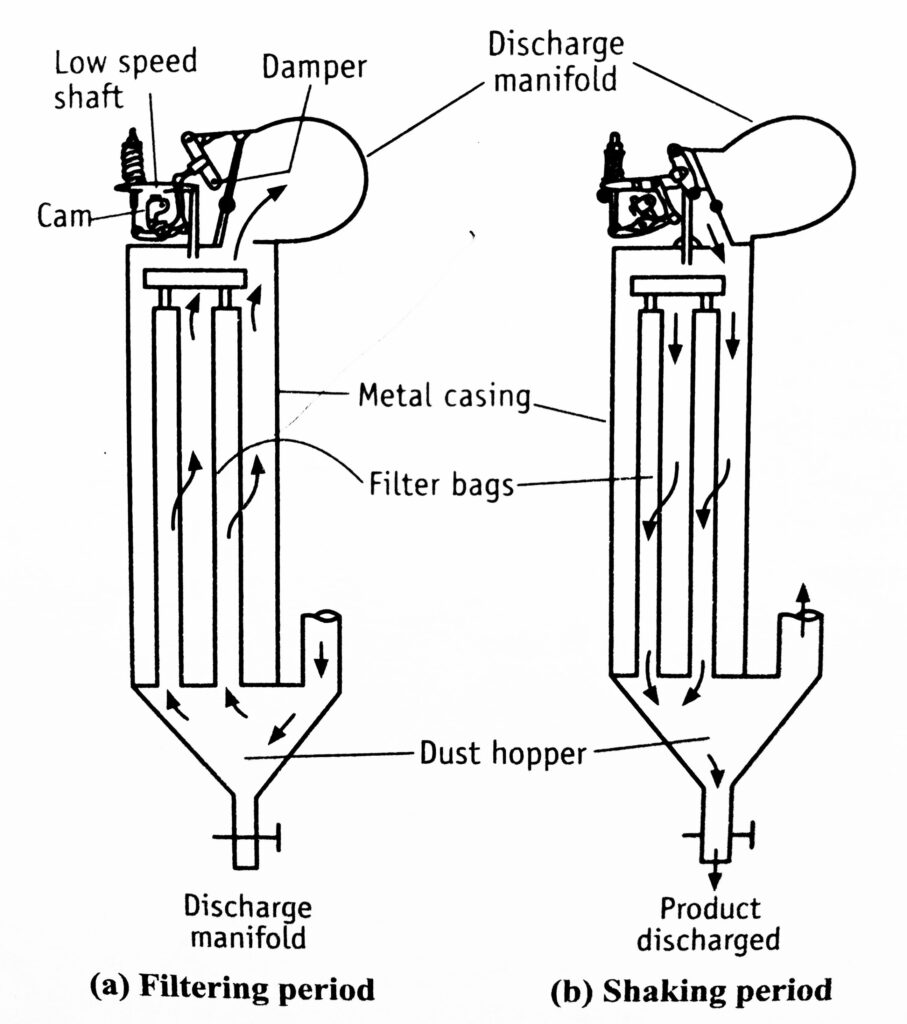

The construction of a bag filter is shown in Figure 2. It consists of a number of bags made of cotton or wool fabric. These are suspended in a sheet metal container.

A hopper is arranged at the bottom of the filter to receive the feed. At the top of the metal container, a provision is made for the exhaust.

Adjacent to this, a bell crank lever arrangement is made to bring the filters to normal atmospheric conditions.

Working

The working of the bag filter consists of two steps. In the first step, the feed is separated from the air by passing it through the cloth bags. In the subsequent step, the bags are shaken to collect the fines that are adhered to the bags. These two steps follow in succession and are controlled at different intervals with the help of a bell crank lever arrangement.

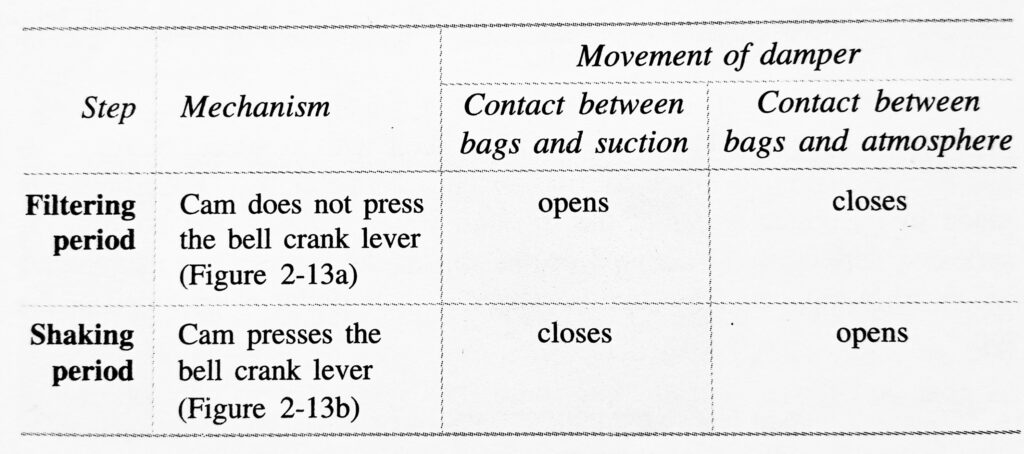

Bellcrank lever arrangement: In this mechanism, a shaft with a cam is allowed to rotate at a low speed. During rotation, the cam can either press the bell crank lever or not come into contact. Depending on. this mechanism, the damper changes its position. The damper is a useful mechanism, which allows the two steps to occur as shown below.

These changes occur at intervals of a few minutes

Filtering period: The exhaust fan positioned at the top keeps the bags under less pressure than atmospheric pressure. The gas containing fine particles (or dust) enters the hopper, as shown with arrows in Figure 2a, and passes up. The gas feed passes through the fabric of the bag. During this process, the fines (or dust) are retained in the bags, while the gas reaches the top of the casing. Because of air, the bag remains taut during filtering operation.

Shaking period Since the vacuum is cut off in the chamber, air from outside enters the casing and passes through the bags. This results in violent shaking of the bags so that the dust and fine particles are displaced from the bags and fall into the conical base. It is then removed at intervals.

Such devices are entirely automatic in their action and can be designed to affect a very large filtering surface per unit of floor space.

Uses of Bag Filter

Bag filters are used along with other size separation equipment, for example, a cyclone separator. Bag filters are used to remove the fines from cyclone discharge. The bag filter is connected to the discharge end of the fluidized energy mill.

Advantages:

- A bag filter is extremely useful for removing fines, which cannot be separated by other methods.

- These can be used even to remove dust. The ordinary household vacuum cleaner is a simple bag filter.

Disadvantage: Bag filter is not size separation equipment as such.

Make sure you also check our other amazing Article on : Air Separator