What is filter media?

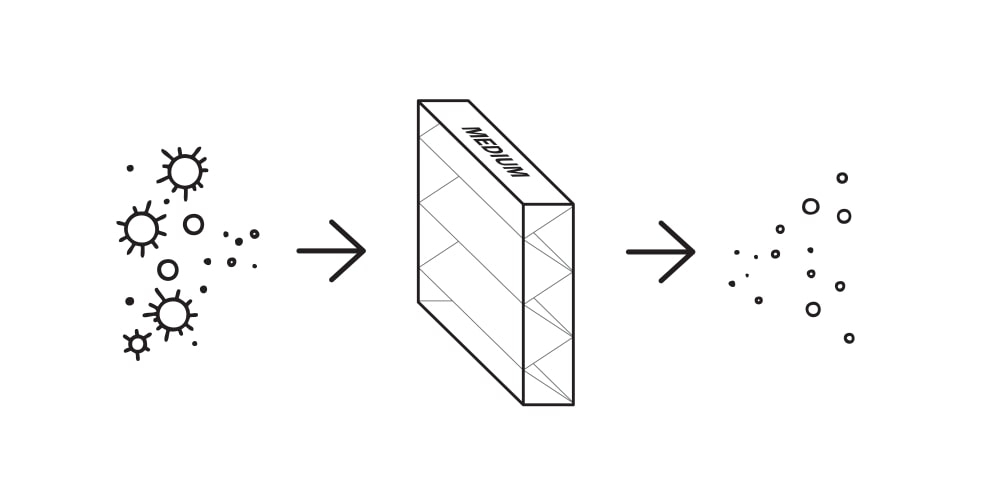

Filter Media are the filter medium that acts as a mechanical support for the filter cake and is also responsible for the collection of solids.

Characteristics of the filter medium

Filter medium should have the following characteristics.

- It should have sufficient mechanical strength.

- It must be inert, for example, it should not show chemical or physical interaction.

- It should not absorb dissolved material.

- It should allow the maximum passage of liquid while retaining the solids. It means that it must offer low resistance to flow. The resistance offered by the filter medium is not significant in large scale operations and can be neglected…

The magnitude of the resistance of the filter medium will change due to the layers of solids deposited earlier, which may block the pores or may form bridges over the channels. Therefore, the pressure should be kept low at the beginning to avoid the plugging of the pores. The usual procedure is to filter at a constant rate by increasing the pressure as necessary. When the normal working pressure is reached, it is maintained. On continued filtration, the thickness of the cake further builds up and hence the rate of filtration decreases. When the rate is uneconomical, filtration is stopped. The filter cake is removed and filtration is restarted.

Materials of the filter medium

The following materials are used as filter media.

Woven materials such as felt or cloth: Woven material is made of wool, cotton, silk, glass, metal or synthetic fibres (rayon, nylon etc.). Synthetic fibres have greater chemical resistance than wool or cotton, which are affected by alkali and acid, respectively. The choice of fibre depends on the chemical reactivity of the slurry.

Perforated sheet metal: For example, stainless steel plates have pores which act as channels as in the case of MetaFilter (edge filter).

Bed of granular solid built upon a supporting medium: In some processes, a bed of graded solids may be to reduce the resistance to the flow. Typical examples of granular solids are gravel, sand, asbestos, paper pulp and kieselguhr. The choice of solids depends on the size of the solids in the process.

Prefabricated porous solid unit: Porous solids prefabricated into a single unit are being increasingly used for their convenience and effectiveness. Sintered glass, sintered metal, earthenware and porous plastics are some of the materials used for the fabrication.

Membrane filter media: Cartridge units are economical and available in pore sizes of 100 µm to even less than 0.2 µm. These can be used either as surface cartridges or depth type cartridges.

- Surface type cartridges: These are corrugated and resin treated papers. These are used in hydraulic lines. Ceramic cartridges are advantageous in cleaning for reuse by backflushing or firing. Porcelain filter candles are used for sterile filtration.

- Depth type cartridges: These are made of cotton, asbestos or cellulose. These are disposable items since cleaning is not feasible.

Make sure you also check our other amazing Article on : Factors Influencing Filtration