Humidification is the process of increasing the moisture in the air…

This is achieved using absorption refrigeration.

Table of Contents

Applications of Humidification

In the pharmaceutical industry, if special conditions are not prescribed, the humidity requirement for various operations is from 20 to 30% RH and the temperature is within the range of 20-27 °C. Hence, dry weather humidification is necessary.

Mechanism of Humidification

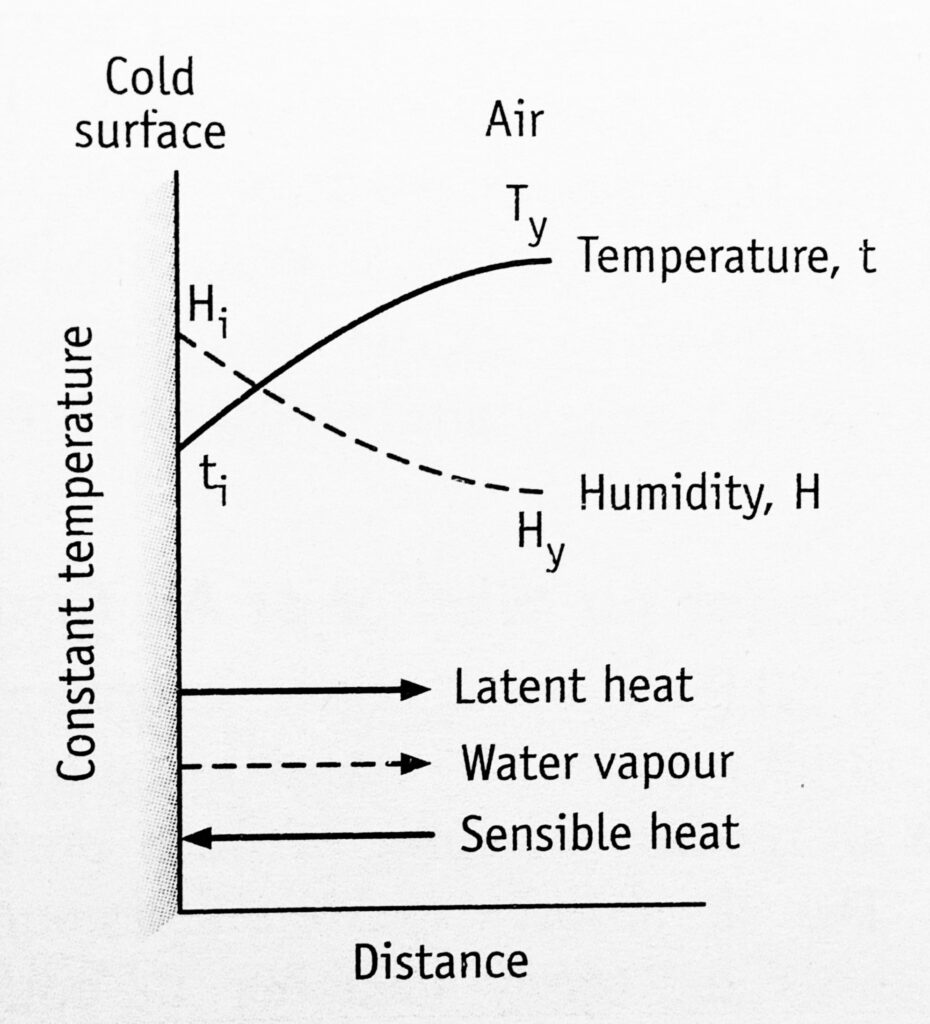

The interaction of gas and liquid and the conditions of humidification are shown in Figure 1. The x-axis indicates the perpendicular distance to the interface. The y-axis represents temperature and humidity.

Broken arrows represent the diffusion of vapour through the gas. phase. Continuous arrows represent the flow of heat (both latent and sensible) through the gas and liquid phases.

In adiabatic humidification, the air is in contact with the liquid at a constant temperature. The humidity at the interface (Hi) must be greater than the humidity (Hy) of the gas so that the air gets humidified. Since water is vaporised, the latent heat is transferred from the liquid to gas. The gas temperature (ti) must be higher than the interface temperature (ty) in order that sensible heat may flow to the interface. (Heating or cooling without the addition or subtraction of moisture content is called sensible heating or cooling).

Hi and ti represents equilibrium conditions of the interface (saturation conditions). Latent heat flows from liquid to gas and sensible heat flows from gas to liquid get balanced. Therefore, there is no temperature gradient in the liquid.

Approaches to Humidification

By spraying water into the air path, cooling and humidification are achieved to the desired level, of the ambient condition; the temperature is higher than the dew point temperature and lower than the dry-bulb temperature.

- The air may be brought into contact with water in such a way that only a part of the water is evaporated. This is the most common method. For this purpose, cooling towers are utilized. Spray ponds, natural draft cooling towers or mechanical draft cooling towers are a few methods in which discharged warm water (from a condenser) is cooled by intimate contact with unsaturated air.

- The incoming air is heated to a higher temperature and then cooled adiabatically with water to achieve desired humidity.

- The ambient conditions are saturated by water spraying. Then the air is heated to the desired temperature. The equipment for achieving humidification is illustrated in the section on Air Conditioning”.

- Air may be mixed with a stream of air of higher humidity (dilution method). This is used in laboratory work.

In a refrigeration system, heat is transferred from a low-temperature environment to a high-temperature surrounding. In other words, heat is thrown against the temperature gradient. For this purpose, energy must be supplied from an external source, mechanical, electrical or thermal. This type is known as A/C mode. The removal of heat in the modern refrigeration unit is accomplished based on phase changes in the refrigerants.

Adiabatic Saturation (or Air Washer or Air Cooler)

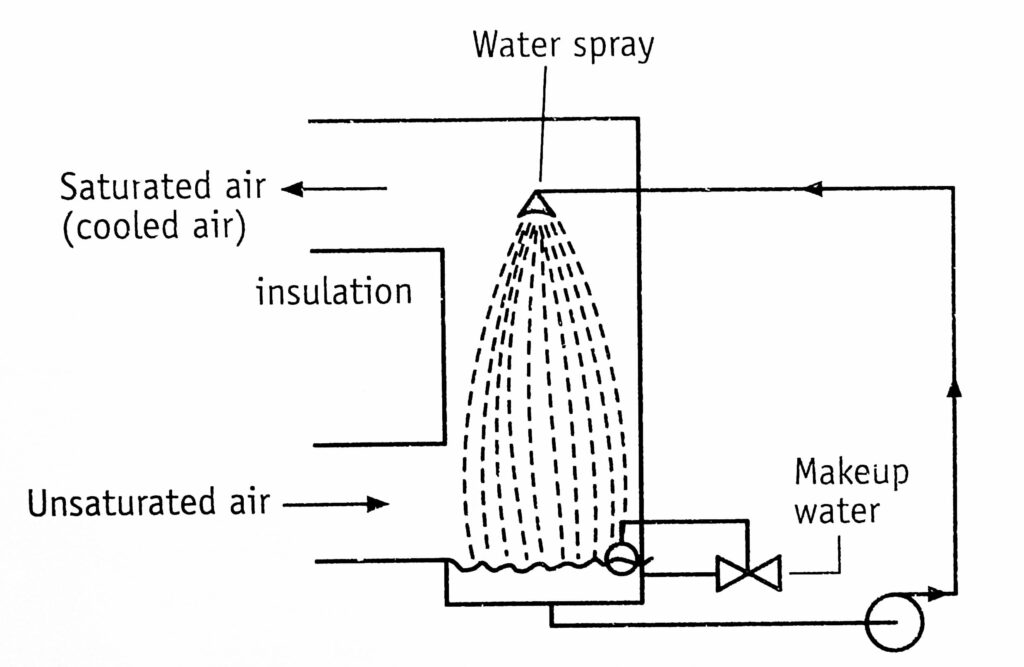

Humidification is achieved by adiabatic saturation. This principle is used in an air washer or air cooler. The construction of the air washer is shown in Figure 2. In an air washer, the spray of water provides a greater surface area for the air. The air absorbs the maximum amount of water vapour. The cooled air leaves the spray chamber in equilibrium with both the temperature and vapour pressure of water. The saturator walls are insulated. It is necessary to provide makeup water to compensate for the amount of water evaporated into the air.

The enthalpy of air entering the air washer and enthalpy of air leaving the air washer is the same, i.e., no change in enthalpy, because of the principle of adiabatic saturation. The latent heat required for evaporation of water (during spraying) is taken from the sensible heat of the air itself. As a result, dry bulb temperature drops. The same conditions are illustrated in Figure 1.

Make sure you also check our other amazing Article on : Measurement of Humidity