In a perforated basket centrifuge, a basket is mounted above a driving shaft. Such an arrangement is described as under-driven. Conversely, if the basket is suspended from a shaft, it is described as over-driven. These are used for batch processes. An under-driven bowl centrifuge is described below.

Table of Contents

Principle

A perforated basket (bowl) centrifuge is a filtration centrifuge. The separation is through a perforated wall based on the difference in the densities of solid and liquid phases. The bowl contains a perforated sidewall. During centrifugation, the liquid phase passes through the perforated wall, while the solid phase is retained in the bowl. The solid is removed after cutting the sediment with a blade after stopping the centrifuge.

Construction

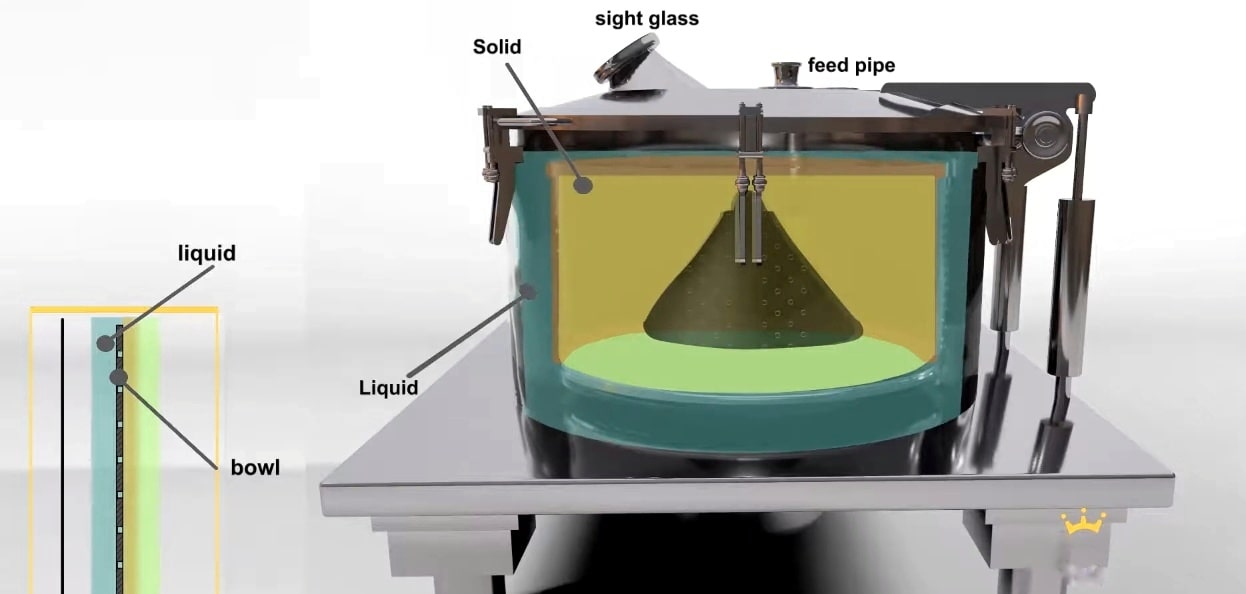

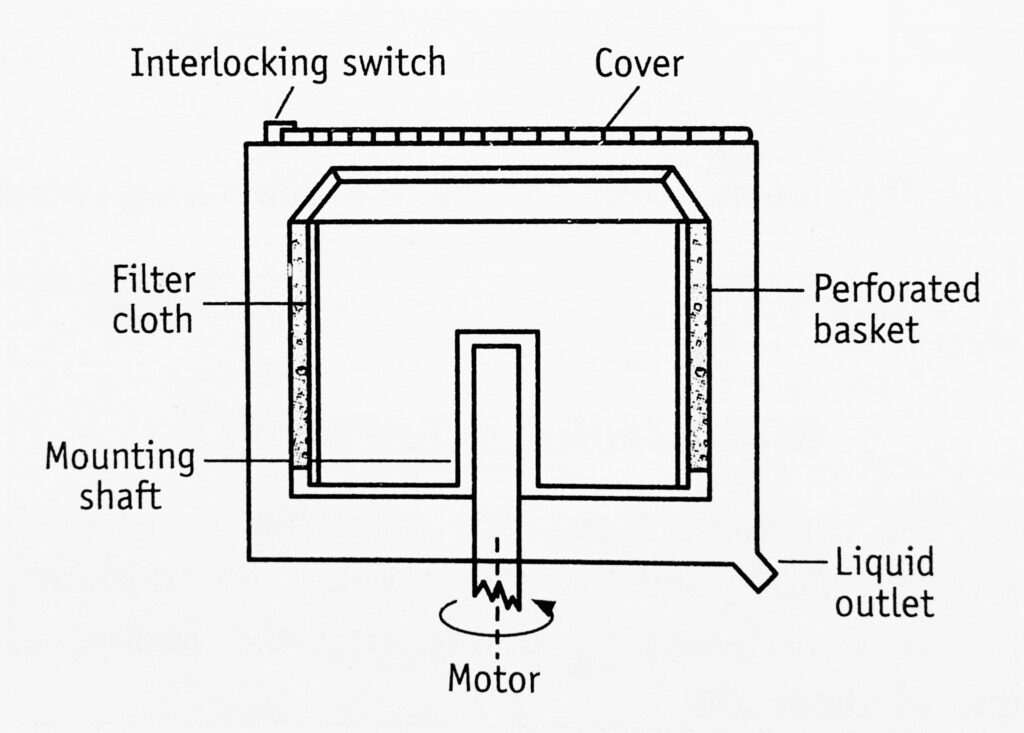

The construction of an under-driven perforated basket centrifuge is shown in Figure. It consists of a basket, made of steel (sometimes covered with vulcanite or lead) or copper or money or any other suitable metal. The basket material of construction should be such that it offers the greatest resistance to corrosion. The basket may have a diameter of 0.90 metres and a capacity of 0.085 metres cube. The diameter of the perforations should be selected based on the size of the crystals to be separated. In case, the size of perforations is bigger than that of the particles, a filter cloth is employed.

The basket is suspended on a vertical shaft and is driven by a motor using suitable power systems such as belt pulleys, water turbines and electric motors. The basket may require about 5-kilowatt power for starting and 2-kilowatt power for running. Sometimes, steel hoops are used externally to strengthen the basket. Surrounding the basket, a casing (stationary) is provided which collects the filtrate and discharges it at the outlet.

Working

The material (feed) is kept in the basket when the basket is stationary. The amount of material should be optimum, otherwise, centrifugation puts a great strain on the basket. The loading of material must be done to give even distribution. Power is applied to rotate the basket and maximum speed must be attained quickly. The basket runs at 1000 revolutions per minute. The power required for running is small compared to the power required for starting and bringing it to the full speed…

During centrifugation, the liquid passes through the perforated wall, while the solid phase remains in the basket. The liquid leaves the basket and is collected at the outlet. The cake is then spun to dry as much as possible. Sometimes higher speeds are used so that the cake will be completely dried. After a definite period of time, the power is turned off. By applying a brake the centrifuge is stopped. The basket is brought to rest. The solid cake is cut using a blade and then unloaded manually.

Uses

- A perforated basket centrifuge is extensively used for separating crystalline drugs (such as aspirin) from the mother liquor. The free-flowing product can be obtained because the mother liquor is removed completely.

- It is also used for removing unwanted solids from a liquid. For example, precipitated proteins are removed from insulin.

- Sugar crystals are separated using a perforated basket centrifuge.

Advantages:

- The centrifuge is very compact and it occupies very little floor space.

- It can handle slurries with a high proportion of solids and even those having paste-like consistency.

- The final product has a very low moisture content.

- In this method, the dissolved solids are separated from the cake.

- The process is rapid.

Disadvantages:

- The entire cycle is complicated resulting in considerable labour costs.

- It is a batch process.

- If the machine is adapted for prolonged operation, there is considerable wear and tear on the equipment. On prolonged operation, the solids may form a hard cake, due to the centrifugal force, which is difficult to remove simultaneously.

Variants: For the separation of fine crystals, the perforations of 3 millimetres in diameter are sufficient. But for finely ground materials, the basket is lined with fine-meshed gauze or with a cloth supported on a coarser gauge.

Make sure you also check our other amazing Article on : Non perforated Basket Centrifuge