Table of Contents

Principle

Plate and Frame filter press based on the mechanism is surface filtration. The slurry enters the frame and flows through the filter medium. The filtrate is collected on the plates and sent to the outlet. A number of frames and plates are used so that surface area increases and consequently large volumes of slurry can be processed simultaneously with or without washing.

Construction

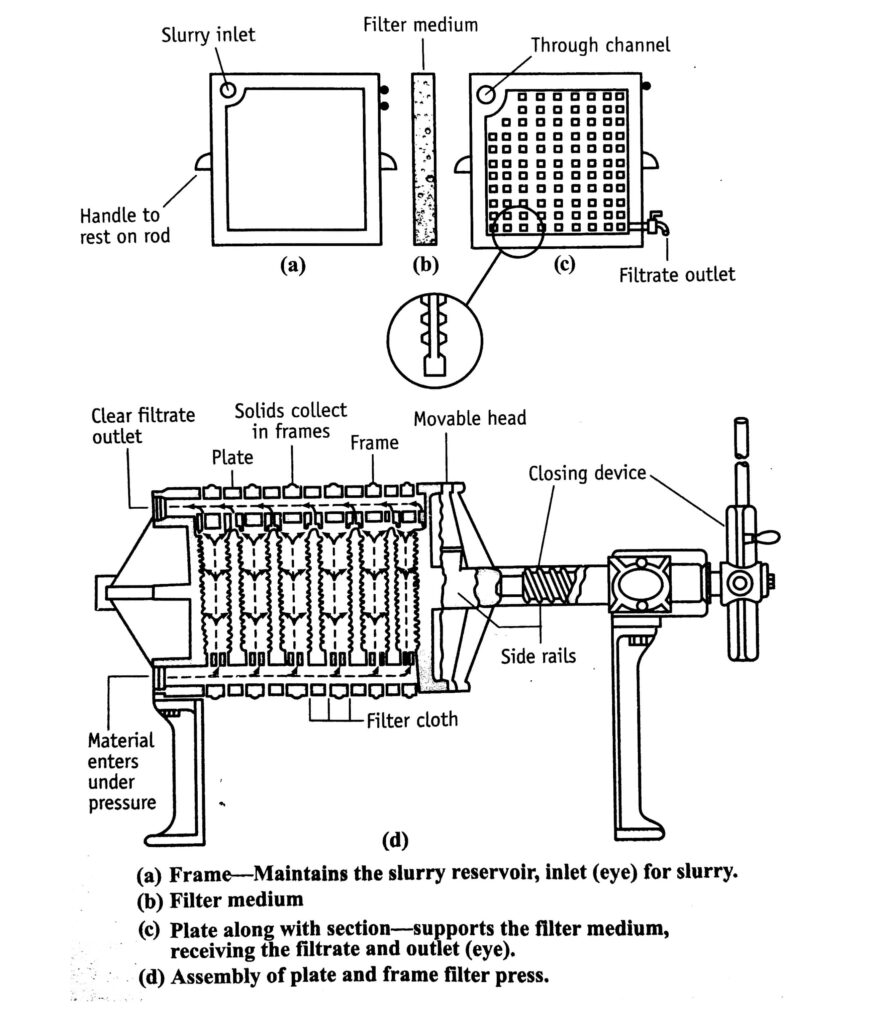

The construction of a plate and frame filter press is shown in Figure 1.1. The filter press is made of two types of units, plates, and frames. These are usually made of aluminum alloy. Sometimes, these are also lacquered for protection against corrosive chemicals and made suitable for steam sterilization.

The frame contains an open space inside wherein the slurry reservoir is maintained for filtration and an inlet to receive the slurry. It is indicated by two dots in the description (Figure 1.1). The plate has a studded or grooved surface to support the filter cloth and an outlet. It is indicated by one dot in the description (Figure 1.1). The filter medium (usually cloth) is interposed between plate and frame.

Frames of different thicknesses are available. It is selected based on the thickness of the cake formed during filtration. The optimum thickness of the frame should be chosen. The plate, filter medium, frame, filter medium, and plate are arranged in the sequence and clamped to a supporting structure. It is normally described by dots as 1.2.1.2.1 and so on. A number of plates and frames are employed so that the filtration area is as large as necessary. In other words, a number of filtration units are operated in parallel. Channels for the slurry inlet and filtrate outlet can be arranged by fitting eyes to the plates and frames, these join together to form a channel.

In some types, only one inlet channel is formed, while each plate is having individual outlets controlled by valves.

Working

The working of the frame and plate process can be described in two steps, namely filtration and washing of the cake (if desirable).

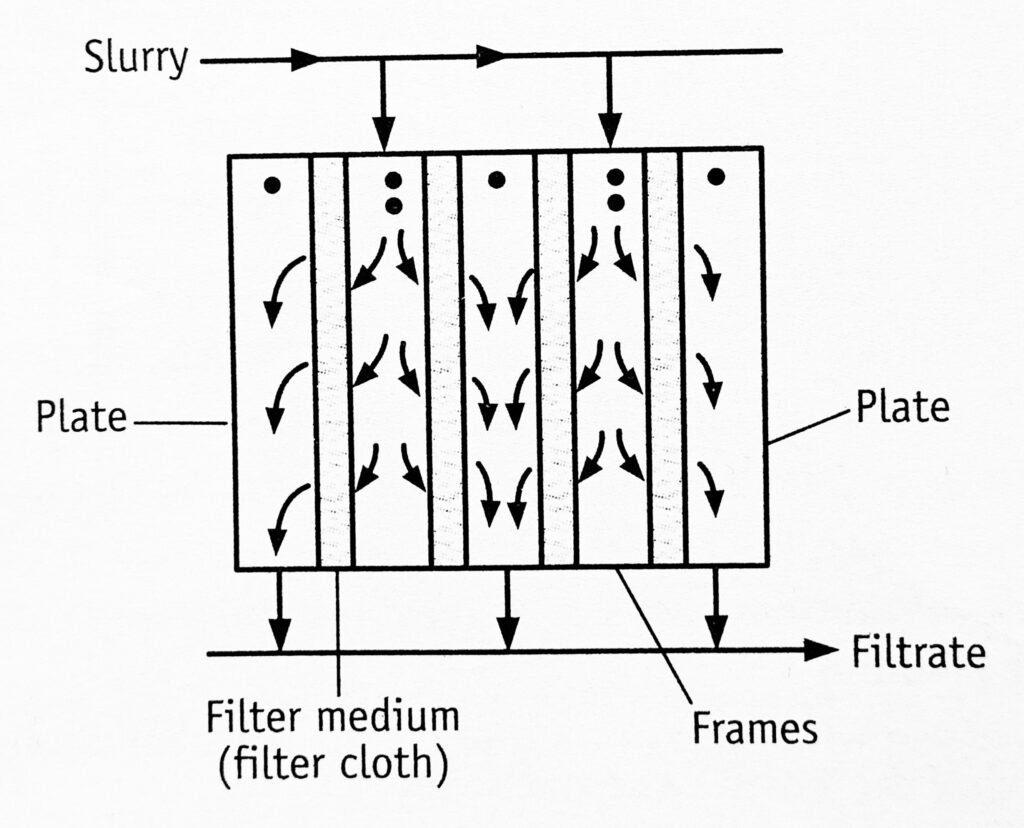

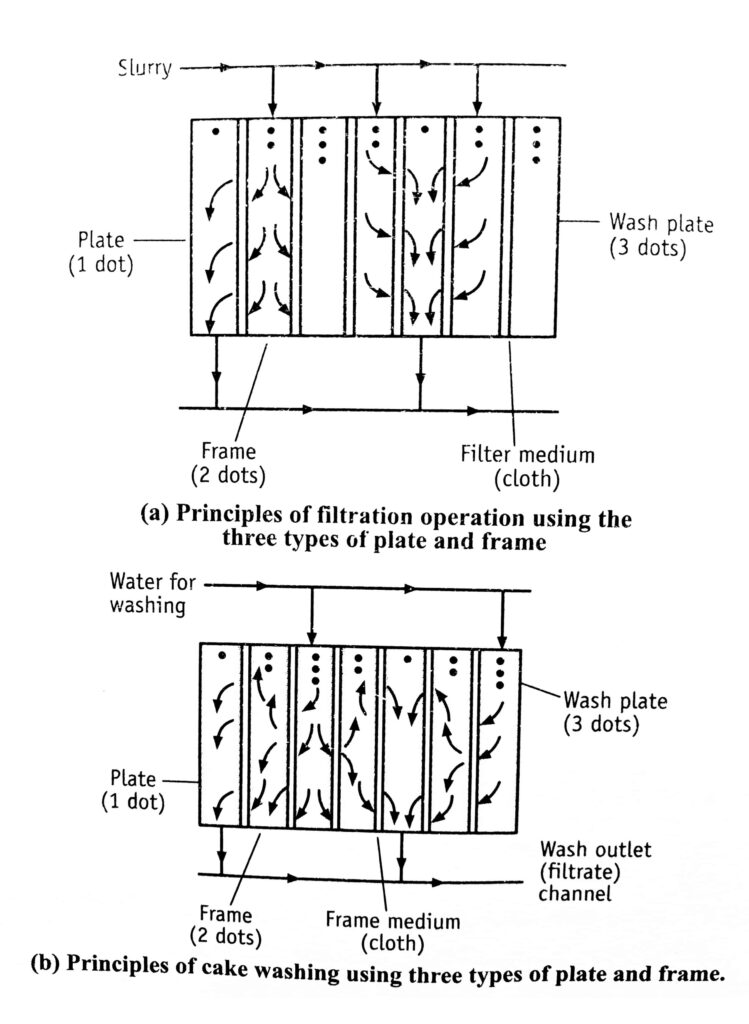

Filtration operation: The working of a plate and frame press is shown in Figure 1.2. Slurry enters the frame (marked by 2 dots) from the feed channel and passes through the filter medium onto the surface of the plate (marked by 1 dot). The solids form a filter cake and remain in the frame. The thickness of the cake is half of the frame thickness because on each side of the frame filtration occurs. Thus, two filter cakes are formed, which meet eventually in the center of the frame. In general, there will be an optimum thickness of filter cake for any slurry. depending on the solid content in the slurry and the resistance of the filter cake.

The filtrate drains between the projections on the surface of the plate and escapes from the outlet. As filtration proceeds, the resistance of the cake increases, and the filtration rate decreases. At a certain point, it is preferable to stop the process rather than continue at very low flow rates. The press is emptied and the cycle is restarted.

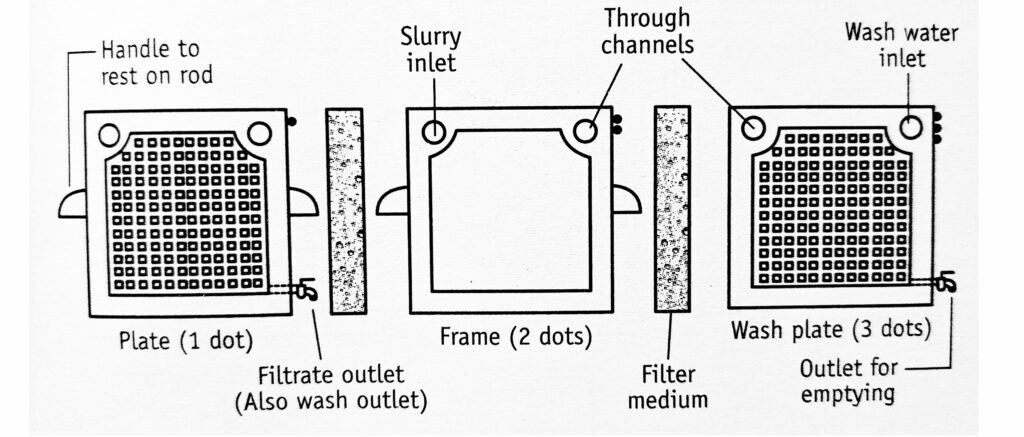

Washing operation: If it is necessary to wash the filter cake, the ordinary plate and frame press is unsatisfactory. Two cakes are built up. in the frame meeting eventually in the middle. This means that flow is brought virtually to a standstill. Hence, water washing using the same channels of the filtrate is very inefficient, if not impossible. A modification of the plate and frame press is used. For this purpose, an additional channel is included (Figure 1.3). These wash plates are identified by three dots. In half the wash plate, there is a connection from the wash water channel to the surface of the plate.

The sequence of arrangement of plates and frames can be represented by dots as 1.2.3.2.1.2.3.2.1.2.3.2.1 and so on (between 1 and 1. 2.3.2 must be arranged). Such an arrangement is shown in Figure 1.4 (a) and (b) for the operations of filtration and water washing, respectively. The procedure for washing the press is shown in Figure 1.4. The steps are as follows.

- Filtration proceeds in an ordinary way until the frames are filled with cake.

- To wash the filter cake, the outlets of the washing plates (three dots) are closed.

- Wash water is pumped into the washing channel. The water enters through the inlets onto the surface of the washing (three dots) plates.

- Water passes through the filter cloth and enters the frame (two dots), which contains the cake. Then water washes the cake, passes through the filter cloth, and enters the plate (one dot) down the surface.

- Finally washed water escapes through the outlet of that plate.

Thus with the help of special washing plates, it is possible for the wash water to flow over the entire surface of the washing (three dots) plate so that the flow resistance of the cake is equal to all points. Hence, the entire cake is washed with equal efficiency.

It should be noted that water-wash is efficient only if the frames are full with filter cake. If the solids do not fill the frame completely, the wash water causes the cake to break (on the washing plate side of the frame), and then washing will be less effective. Hence, it is essential to allow the frames to become completely filled with the cake. This helps not only in emptying the frames but also helps in washing the cake correctly.

Special provisions:

- Any possible contamination can be observed by passing the filtrate through a glass tube or sight glass from the outlet on each plate. This permits the inspection of the quality of the filtrate. The filtrate goes through the control valve to an outlet channel.

- The filtration process from each plate can be seen. In the event of a broken cloth, the faulty plate can be isolated and filtration can be continued with one plate less.

Uses of Plate and Frame filter press

Filter sheets composed of asbestos and cellulose are capable of retaining bacteria, so that sterile filtrate can be obtained, provided that the whole filter press and filter medium have been previously sterilized. Usually, steam is passed through the assembled unit for sterilization.

Examples include the collection of precipitated antitoxin, removal of precipitated proteins from insulin liquors, and removal of cell broth from the fermentation medium.

Heating/cooling coils are incorporated in the press so as to make them suitable for the filtration of viscous liquids.

Advantages of Plate and Frame filter press:

1. The construction of the filter press is very simple and a variety of materials can be used.

- Cast iron for handling common substances.

- Bronze for smaller units.

- Stainless steel is used thereby contamination can be avoided.

- Hard rubber or plastics where metal must be avoided.

- Wood for lightness though it must be kept wet.

2. It provides a large filtering area in relatively small floor space. It is versatile, the capacity is variable according to the thickness of frames and the number used. Surface area can be increased by employing chambers up to 60.

3. sturdy construction permits the use of considerable pressure differences. About 2000 kilopascals can be normally used.

4. Efficient washing of the cake is possible.

5. Operation and maintenance are straightforward because there are no moving parts, and filter cloths are easily renewable. Since all joints are external, a plate can be disconnected if any leaks are visible. Thus contamination of the filtrate can be avoided.

6. It produces dry cake in the form of a slab.

Disadvantages:

- It is a batch filter, so there is a good deal of ‘down-time’, which is non-productive.

- The filter press is an expensive filter. The emptying time, the labor involved and the wear and tear of the cloth result in high costs.

- Operation is critical, as the frames should be full, otherwise washing is inefficient and the cake is difficult to remove.

- The filter press is used for slurries containing less than 5% solids. So high costs make it imperative that this filter press is used for expensive materials. Examples include the collection of precipitated antitoxin and the removal of precipitated proteins from insulin liquors.

Make sure you also check our other amazing Article on : What are filter aids