Table of Contents

Principle

The principle of the roller mill is breaking and crushing actions are achieved mechanically with the application of pressure. Stress is applied by rotating heavy corrugated wheels (mullers or rollers). The oil is squeezed out from the solid material.

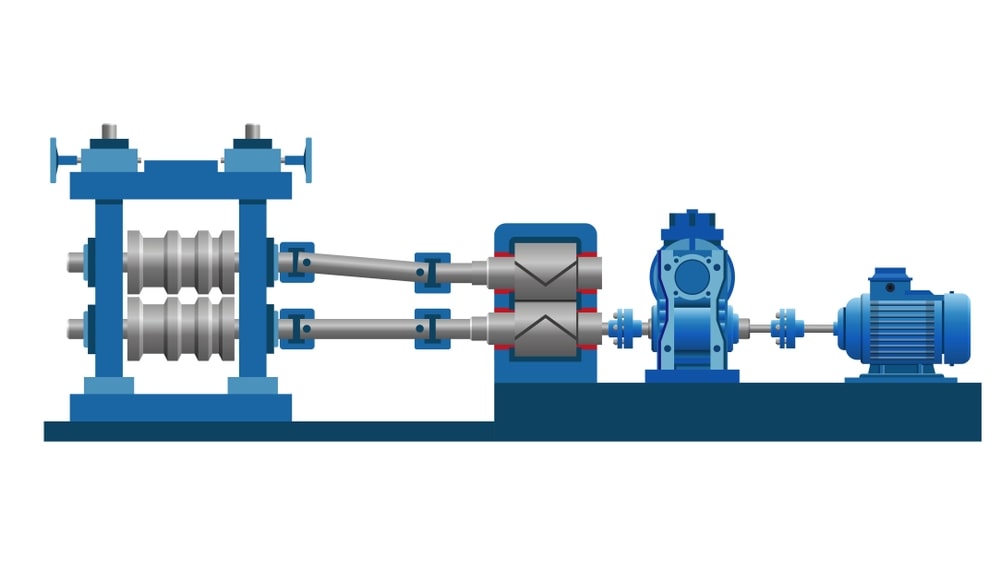

Construction

The construction of a roller mill is shown in Figure. It consists of three rollers, with one roller moving above and between the other two. The rollers are made of cast iron, corrugated or grooved in various patterns. A feed filling mechanism provides the necessary force to allow the feed to pass through the first pair of rollers, either by the use of a small mill opening or a high rate of feed.

Working

The rollers are allowed to rotate. The material is fed from the hopper into the gap between the rollers (1 and 2). The material is squeezed between the top and second roller and is then directed into the nip of the top and third roller for a second time pressing. The clearance between the rollers can be adjusted to control the degree of pressing. The material is pressed (shearing and crushing) against each roller by rams. The product is collected into the receiver.

Pharmaceutical Uses

Roller mills are used in the cane-sugar industries. In this, trains of four or seven rollers are used. Crushing of the cane is carried between rollers, as the feed is introduced by an apron conveyor.

In de-watering of paper, a two-roller mill is used, usually supported on a felt. A double roller mill is used to squeeze the water (or process liquid) in the final step of textiles. In dyeing, the cloth is thoroughly impregnated with small quantities of dye and is successively squeezed with pad rolls.

Make sure you also check our other amazing Article on : Screw Press