Table of Contents

Principle

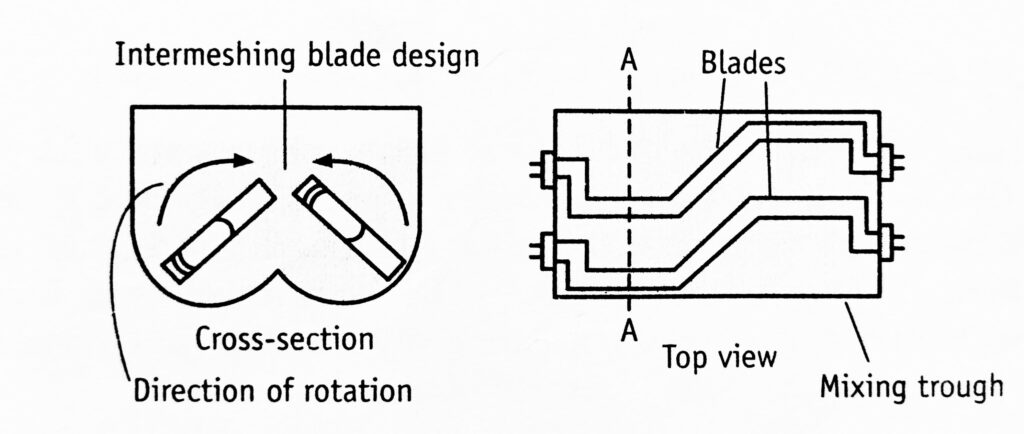

The mechanism of Sigma Blade Mixer is that mixing is shearing. The inter-meshing. of sigma-shaped blades creates high shear and kneading actions. Convective mixing is achieved by cascading the material.

Construction of Sigma Blade Mixer

The construction of a sigma blade blender is shown in Figure 1. It consists of a double trough-shaped stationary bowl. Two sigmas (indicating the shape of the Greek letter) shaped blades are fitted horizontally in each trough of the bowl. These are connected to a fixed-speed drive. The mixer is loaded from the top and unloaded by tilting the entire bowl by means of a rack-and-pinion drive.

Working

Different powders are introduced from the top of the trough. The body is covered because considerable dust may be evolved during dry blending and granulating solution may evaporate during wet granulation.

Through the fixed-speed drive, the sigma blades are allowed to rotate. The blades move at different speeds, one usually about twice the speed of the other, resulting in the lateral pulling of the material. They turn towards each other so that the powders move from the sides to the center of the bowl. The material further moves downwards over the point and then sheared between the blades and the wall of the trough. Thus cascading action (convective) as well as shear action can be achieved. The perforated blades help in breaking lumps and aggregates. Thus high shear forces are set up. The final stage of the mix represents an equilibrium state. The operating conditions of a given mixer can markedly affect the steady-state and thus the quality of the mixing. By means of a rack-and-pinion drive, the bowl is tilted to empty the blend.

Uses of Sigma Blade Mixer

A Sigma blade mixer is commonly used for the mixing of dough ingredients in the baking industry. It is used in the wet granulation process in the manufacture of tablets, pill masses, and ointments. It is primarily used for liquid-solid mixing, although it can be used for solid-solid mixing.

Advantages:

- The sigma blade mixer creates a minimum dead space during mixing.

- It has close tolerances between the blades and the side walls as well as the bottom of the mixer shell.

Disadvantage: This blade machine mixer works at a fixed speed.

Make sure you also check our other amazing Article on : Ribbon Blender