Principle

The differential speed and the narrow space between the rollers develop high shear over the material. Triple Roller Mill shear causes the crushing of aggregates, and particles and also distributes the drug uniformly throughout the semisolid base.

Construction

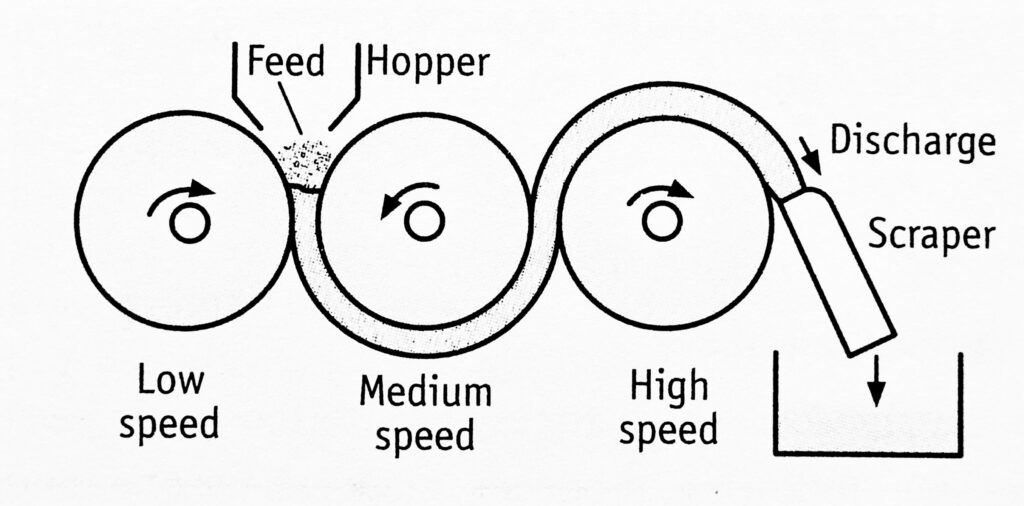

The construction of a triple roller mill is shown in Figure. It consists of three parallel rollers of equal diameters. These are made up of hard abrasion-resistant material, normally stainless steel. The rollers are mounted in a rigid framework horizontally. The pressure and gap between the rollers are independently adjustable. A hopper is arranged between the first two rollers. A scraper is attached to the last roller.

Working

The gap between the last two rollers is adjusted to be less than the gap between the first two rollers. The rollers are rotated at different speeds. In practice, the first roller (receiving-roller) rotates at a slower speed compared to the second roller. Similarly, the second roller’s speed is less than that of the third roller (discharge roller).

The feed is passed through the gap between the first and second rollers. The aggregates and particles are crushed and then abraded by the rubbing action of the rollers, which is developed due to differences. speeds of rotation. A film of an appreciable thickness of the feed is produced. The material passes from a slow rotating to a fast-rotating roller. Between the second and third roller, the gap is small and produces a thinner film of feed. The speed of the third roller is increased to compensate for the reduction of the cross-sectional area. In the thinning film, more crushing and more abrasion are developed.

Finally, the scrapper removes the material completely from the last roller which can be collected immediately into the receiver or transported through a suitable conveyor.

Advantage: Triple roller mill is suitable for continuous processes. Extremely uniform dispersion is obtained.

Make sure you also check our other amazing Article on : Silverson Emulsifier