The absorption system of refrigeration is the heat-operated unit, which uses a refrigerant that is alternatively absorbed and liberated from the absorbent. Vapour Absorption Refrigeration System is also known as the absorber-generator assembly of refrigeration.

Principle

Absorption refrigeration units employ water as the refrigerant and a strong solution of lithium bromide as absorbent…The vapour absorption refrigeration system principle involves the following steps.

- In a high vacuum chamber, water is flashed to produce vapour. The temperature of the remaining water is lowered. This effect is responsible for refrigeration.

- A strong solution of lithium bromide (hygroscopic salt) absorbs the water vapour produced in the above step. The weak solution is now reconstituted and circulated again. Ammonia is also used as the absorbing solution.

This method is raising the pressure of the refrigerant from evaporative pressure to condenser pressure, without much altering its volume. These events repeat in a cycle, thereby refrigeration is produced continuously. Applications: Lithium bromide based refrigeration finds chilled water applications. It is used for food preservation and comfort cooling. Since water cannot be cooled below 0 °C, it can be used as a refrigerant in an air conditioning unit.

Advantages: Investment and maintenance costs of absorption system of refrigeration are low. Different capacities are possible. It has assumed importance because of the use of solar energy for the generation of heat sources for refrigeration.

Disadvantages: The size of the equipment is high. The coefficient of performance (COP) is low. The requirements for steam and water are large.

Working of Vapour Absorption Refrigeration System

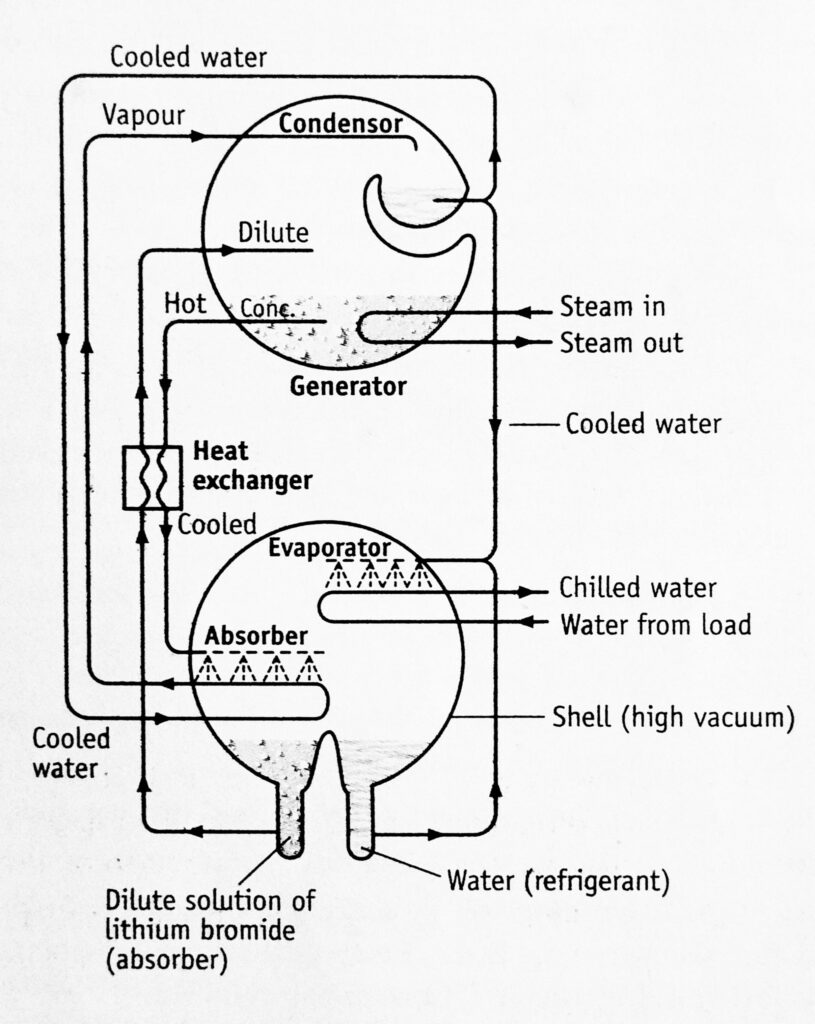

The basic construction of the refrigeration cycle of the absorption system is shown in Figure 1. The cycle operates between evaporation and absorption processes to produce a continuous cooling effect. Lithium bromide solution has a strong affinity for water vapour because of its very low vapour pressure. It absorbs water vapour as fast as it is released in the evaporator. The sequence of events in the refrigeration cycle is explained using basic components.

Evaporation: This part is housed in half of the shell, which is maintained at low absolute pressure. From the environment (which is to be cooled), water is passed through a tube into this part. It is indirectly cooled by spraying water (refrigerant) over the tubes. The sprayed water flashes (due to low absolute pressure) and further cools the chilled water in the tube. This chilled water goes to the environment that is to be cooled and abstracts heat from the chamber. Thus, refrigeration is achieved.

Absorber: This part is housed in the other part of the shell. Cooled water (condensed water from the condenser) is introduced through a tube. The strong solution of lithium bromide is sprayed over the above tube section. This salt solution absorbs water vapour flashed in the evaporator section. As a result, the heat of condensation (of water vapour) is liberated. As the lithium bromide solution is diluted, the heat of the solution is liberated. The sensible heat is given to the solution. All these heats together with refrigeration load (given by evaporator) are absorbed by cooled water (in) the tube) and gets vapourised. The vapour passes to the condenser.

Heat exchanger: In this part, heat is exchanged between the cold dilute solution of lithium bromide and the strong hot salt solution. returning from the generator. The cold salt dilutes solution is heated (vapourised), while the hot strong solution becomes cool. The cycle of efficiency of refrigeration improves, i.e., reducing consumption of steam (generator) and condenser water.

Generator: This part contains steam tubes to provide heat. The water from the dilute lithium bromide solution boils and gets evaporated. As water evaporates, the original salt concentration is restored. This further passes through a heat exchanger and gets cooled. Such cold water is used for spraying the absorber section.

Condenser: The water vapour from the tubes of the absorber reaches this part. Water vapour from the generator section also gets condensed. This cooled water is returned to the tubes of the absorber section. The same condensed water (refrigerant) passed through a liquid trap and was reused to enter the evaporator section for spraying.

Thus, this cycle is repeated thereby producing refrigeration in the enclosed space.

Generally, vapour compression systems are considered first. These can be used for all most every task. Reciprocating compressors are used for lower rates of refrigeration. Centrifugal compressors are used for huge capacities.

Make sure you also check our other amazing Article on : Vapour Compression Refrigeration System