The refrigeration cycle is also known as the vapour compression cycle. This is illustrated using single-stage vapour compression. Vapour Compression Refrigeration System is also known as a mechanical refrigeration system or compression refrigeration system.

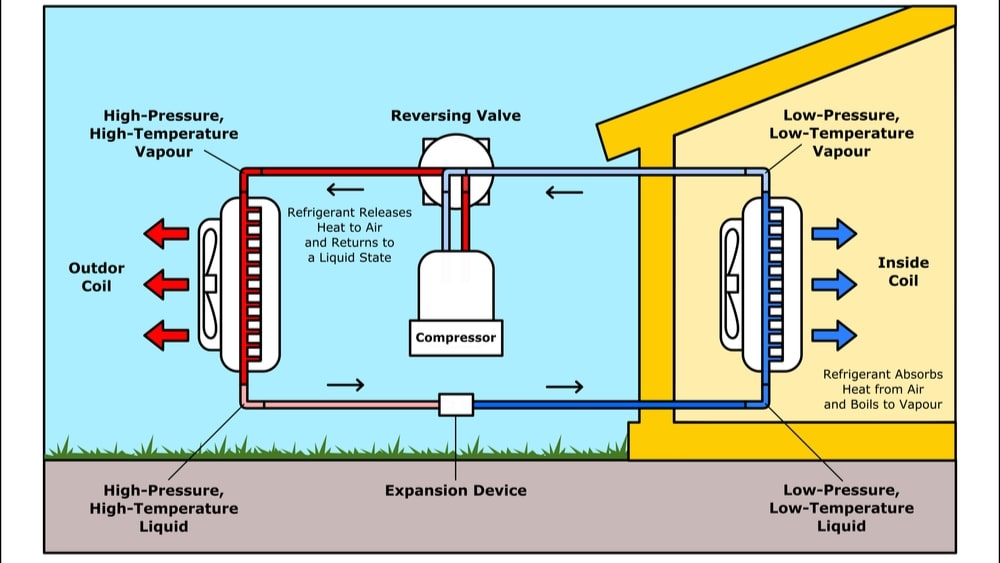

The basic construction of refrigeration cycles is shown in Figure 1. The cycle operates at two pressures, high and low, to enable the process to produce a continuous cooling effect. The sequence of events in the refrigeration cycle or Vapour Compression Refrigeration System is explained by taking basic components in order.

Receiver or condenser: The liquid refrigerant is kept in a container namely a condenser. The refrigerant is under pressure and the vapour and liquid phases are in equilibrium.

Expansion valve: It is a device, which controls the rate of flow of refrigerant into the evaporator, converting the refrigerant from high pressure to low pressure. The refrigerant enters a low-pressure zone.

Evaporator: Subsequently, a mixture of vapour and liquid enters the evaporator, which consists of coils. Here the refrigerant evaporates by absorbing heat from the space. The molecules move apart by breaking intermolecular forces. The energy (heat) required for this process is taken from the surrounding environment, i.e., space, which is to be cooled. In this step. liquid vaporises completely, though some liquid still remains.

Liquid trap: A liquid trap is used to remove liquid, which is: then returned to the receiver (condenser).

Compressor: The saturated vapour is allowed to pass through the compressor During compression, the heat of compression is added to the vapour and the pressure raises. The compression is adiabatic and on the discharge side, it produces a supersaturated gas. The valve should be opened very slowly. A part of the liquid vaporises to give a stream of high velocity.

Condenser: The supersaturated vapour flows to the condenser where the gas is liquefied. These condensers can be air-cooled or water-cooled.

Thus, one cycle is completed as shown in the dehumidification Figure (Approaches for achieving dehumidification) and the process continues.

Make sure you also check our other amazing Article on : Refrigeration