In this article, we discuss what is filtration. What is the process to filter? And what are the applications of filtration?

Definition of filtration

Filtration may be defined as a process of separation of solids from a fluid bypassing the same through a porous medium that retains the solids, but allows the fluid to pass through.

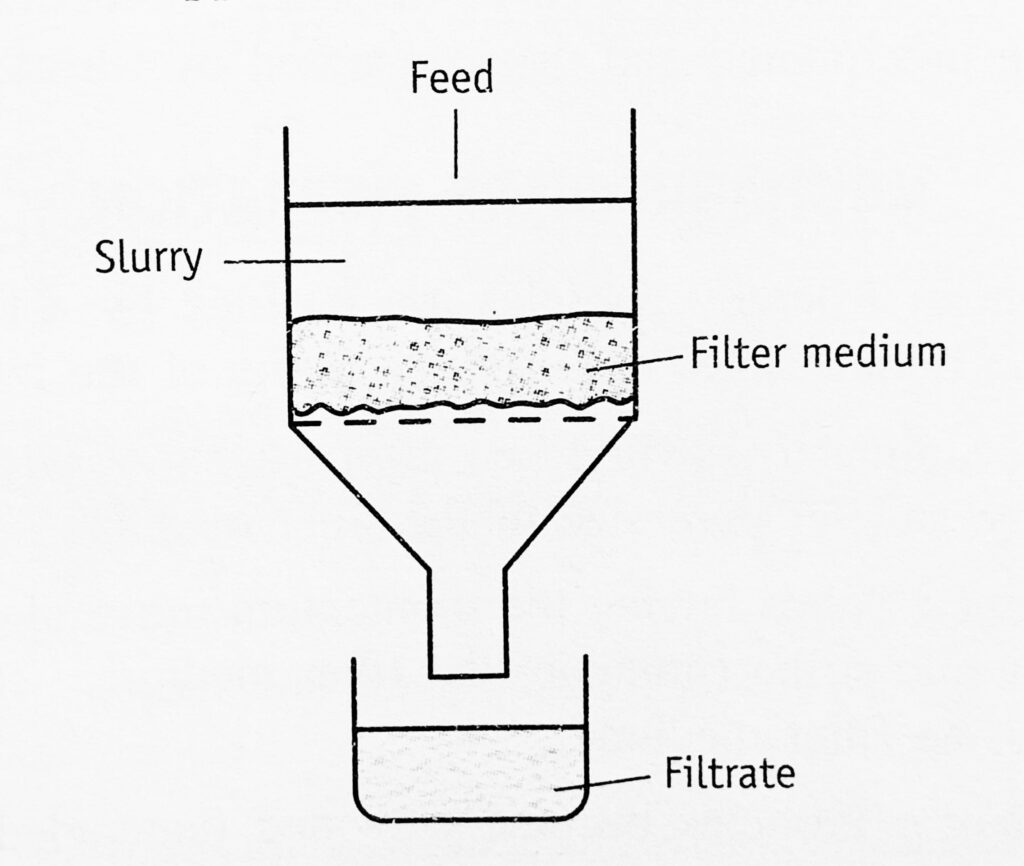

The suspension to be filtered is known as slurry. The porous medium used to retain the solids is known as a filter medium. The accumulated solids on the filter are referred to as filter cake, while the clear liquid passing through the filter is filtrate. When solids are present in a very low concentration, i.e., not exceeding 1.0% w/v. the process of its separation from the liquid is called clarification.

Clarification is generally employed when contaminating material is finely subdivided, amorphous, or colloidal in nature. These solids tend to plug the filter medium. Several other processes having similar mechanisms are decoloration, decantation, colation, expression, etc.

Process of Filtration

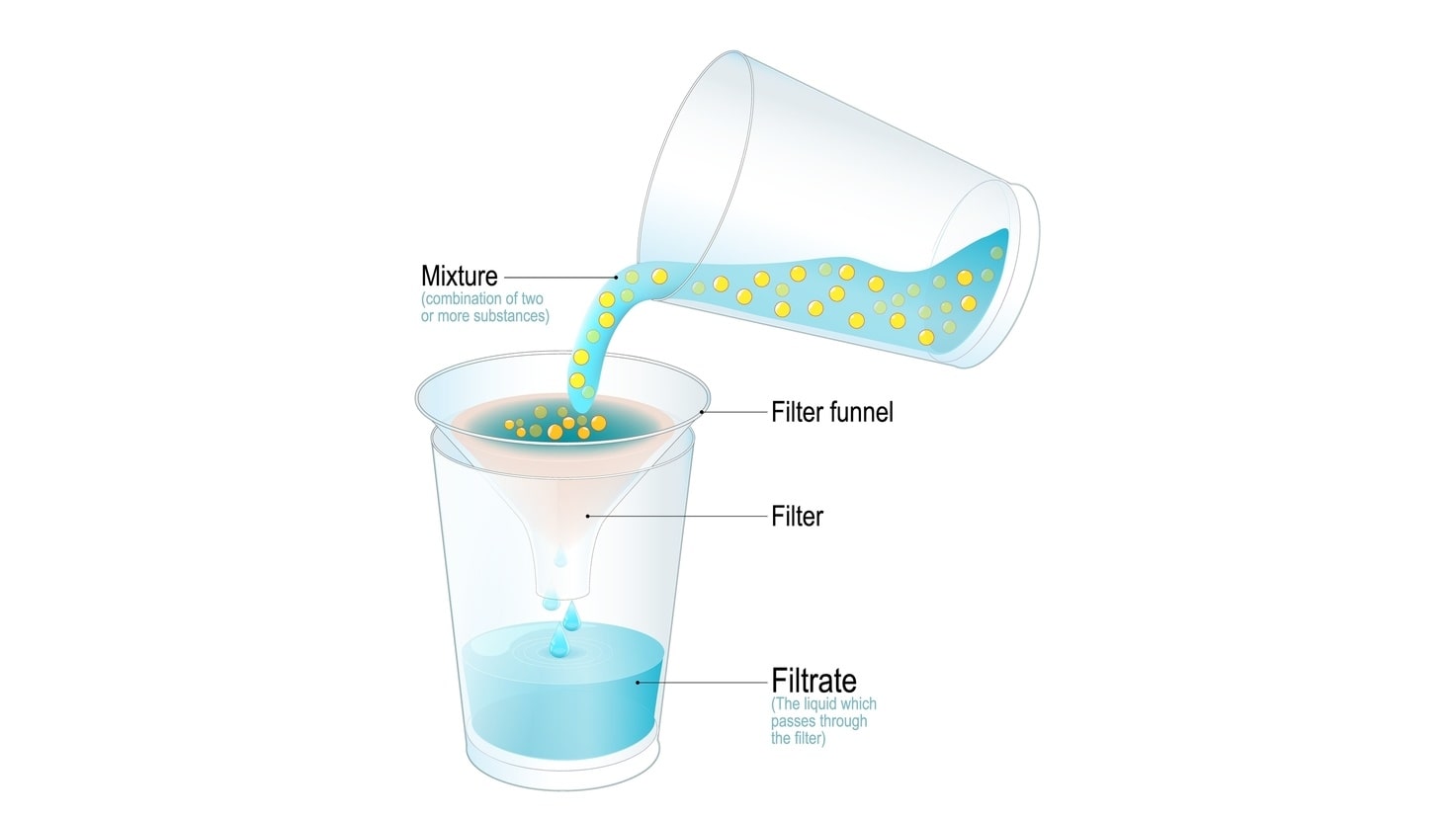

A typical filtration operation is shown in Figure 1.1. The pores of the filter medium are smaller than the size of the particles to be separated. Filter medium (for example filter paper or muslin cloth) is placed on a support (a mesh). When slurry (feed) is passed over the filter medium.

the fluid flows through the filter medium by virtue of a pressure difference across the filter. Gravity is acting on the liquid column. Therefore, solids are trapped on the surface of the filter medium.

Once the preliminary layer of particles is deposited, further filtration is brought about wherein the filter medium serves only as a support. The filter will work efficiently only after an initial deposit. On an industrial scale, large quantities of suspensions are mechanically handled. After a particular point in time, the resistance offered by the filter cake is so high that virtually filtration is stopped. For this reason, a positive pressure is applied on the filter cake (upstream), or negative pressure (suction) is applied below the filter medium (downstream).

Applications of Filtration

Production of sterile products:

Air is filtered through HEPA filters (high-efficiency particulate air filters) or laminar air bench to obtain sterile air, which maintains a good environment prior to and during the manufacture of sterile products.

A solution is passed through a bacteria-proof filter in order to obtain the sterile solution, particularly when heat sterilization is not suitable on account of the thermolabile nature of the contents. In the case of sterile products, particles as small as 0.2 µm should be removed, which includes the bio-burden of fungi, bacteria, etc.

Similar facilities are required for the production of antibiotics by fermentation, recombinant technologies of biological products, and vaccines.

Production of bulk drugs:

Solids of intermediates and finished products are separated from the reaction mixture by the filtration technique. By this method, impurities can be removed.

Production of liquid oral formulations:

Filtration is an essential step in the production of liquid oral solutions for obtaining clear solutions (clarification).

- Dewaxing of oils.

- Removing suspended oils from aqueous solutions. Examples are aromatic waters, syrups, elixirs, eye drops, etc.

- Removing undesirable solids, which interfere with the transparency of the liquids. Examples are honey and fruit juices.

- Clarifying the potable water.

Effluent and wastewater treatment: Waste solids must be separated from the waste liquid prior to its disposal. Sometimes, the soluble components are precipitated and then separated by filtration.

Make sure you also check our other amazing Article on : Perforated Basket Centrifuge