What are filter aids?

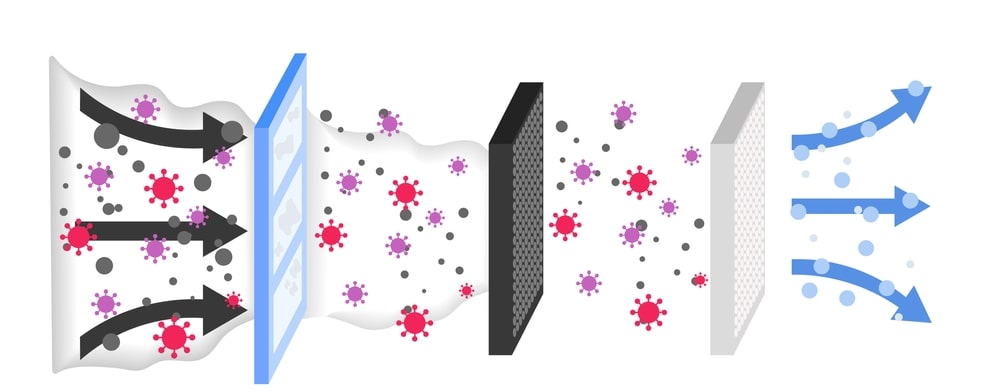

Filter aid forms a surface deposit that screens out the solids and also prevents the plugging of the supporting filter medium.

Justification: The objective of the filter aid is to prevent the medium from becoming blocked and to form an open, porous cake, hence, reducing the resistance to the flow of the filtrate.

- Usually, low resistance is offered by the filter medium itself. But as the layers of solidly built up, the resistance will be increased The cake may become impervious by blocking the pore in the medium. The flow rate is inversely proportional to the resistance of the solid cake.

- Slimy or gelatinous material and highly compressible substances from impermeable cakes. The filter medium gets plugged and the flow of filtrate stops.

Characteristics:

The important characteristics of the filter aids are:

- Chemically inert to the liquid being filtered and free from impurities. liquid.

- Low specific gravity, so that filter aids remain suspended in the liquid.

- Porous rather than dense, so that previous cake can be formed.

- Recoverable.

Disadvantages:

The filter aids remove the colored substances by absorbing them. Sometimes active principles such as alkaloids are adsorbed on the filter aid. Rarely, aids are a source of contaminants such as soluble iron salts, which can provoke degradation of sensitive ingredients. Liquid retained in the pores of the filter cake is lost in the manufacturing process.

Examples of filter aids are:

- Kieselguhr

- Paper pulp

- Talc

- Bentonite

- Charcoal Fullers earth

- Asbestos

Activated charcoal is used for the removal of organic and inorganic impurities. Kieselguhr is a successful filter aid and as little as 0.1 percent can be added to the slurry. The rate of filtration is increased by 5 times or more, at the above concentration, though the slurry contains 20% solids.

Handling of filter aids:

Filter aids are mostly used for clarification processes, i.e., where solids are discarded. Different flow rates can be achieved depending on the grade of the aids.

Low flow rate (fine solids)-Fine grade filter aids-mainly for clarity.

Fast flow rate (coarse solids)-coarse grade filter aids-acceptable filtrate.

The filter aid can be employed in either one or both ways.

- Firstly, a pre-coat is formed over the medium. For this purpose, a suspension of the filter aid is filtered to give a coating up to 0.5 kg per meter square.

- Secondly, a small proportion of filter aid (0.1 to 0.5% of total batch weight) is purposely added to the slurry. So the filter cake has a porous structure and filtration can be efficient. The filter aid of 1 to 2 parts per part of the contaminant is mixed in the feed tank. This slurry is recirculated through the filter until a clear filtrate is obtained. Filtration then proceeds to completion. The body mix method minimizes equipment requirements and cross-contamination potentials.

Make sure you also check our other amazing Article on : Filter Media