Compare to the classical chromatography high-pressure liquid chromatography or high-performance liquid chromatography has much better performance. Compare to classical column chromatography it works under high pressure. HPLC has a smaller particle size for the adsorbent phase so that it provides more surface area which improves the separation.

In HPLC the particle size of stationary phase is less (3-20µm) with a small metal column packed under high pressure which run under high plow rate and high pressure (>5000 psi) while in conventional column chromatography particle size is less (60-200µm) with glass column packed under gravity pressure, run at very low flow rate and work under low pressure (< 20psi).

HPLC runs under normal phase mode or reverse-phase mode which depends upon the polarity of stationary phase and mobile phase. In normal phase mode, the mobile phase is non-polar and the stationary phase is polar while in the reverse phase mode mobile phase is polar and the stationary phase is non-polar.

The separation technique in HPLC may be isocratic or gradient. In the isocratic separation technique, the polarity of the mobile phase is maintained the same throughout the process while in gradient separation the polarity of the mobile phase can be gradually changed by changing the ratio of the different solvents present in the mobile phase.

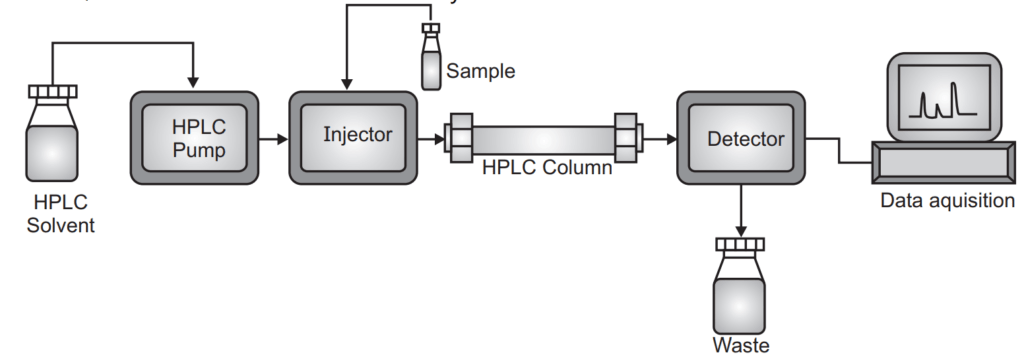

The HPLC unit consists of different parts like the pump, mixing unit, injector, guard column, analytical column, detectors, and recorder. The solvent is pushed into the column under very high pressure (1000 to 5000 psi) because the particle size of the stationary phase is very small (5-10 µm) so the resistance force by mobile phase is very high. To generate such pressure mechanical or pneumatic pumps are used. The mechanical pump works under constant flow rate and for generally analytical purposes. Pneumatic pumps work under constant pressure with highly compressed air. Flow rate and back pressure are controlled by the check valve. The pulse generated by the pump is dampened by pulse dampeners. In the mobile phase, there may be a single solvent or maybe more than one solvent. To mix properly more than one solvent there is a mixing unit in the HPLC apparatus. It may be two types a) low pressure mixing chamber b) high-pressure mixing chamber. In a low-pressure mixing chamber, helium is used for degassing the solvent. The quality of solvent should be very good or maybe HPLC grade.

Various gases are soluble in the mobile phase. Mobile phase under high pressure, when pumped in soluble gas, becomes undissolved and forms the bubble which interferes with the separation of constituents. To remove this hindrance the degassing of the mobile phase is very important. For degassing the various techniques like vacuum filtration, helium purging, ultrasonication can be used. Vacuum filtration is not very much reliable, helium purging is efficient but helium is costly gas so that ultrasonication is the better technique. Ultrasonicator removes the air bubble into the mobile phase by converting ultra-high frequency into mechanical vibration.

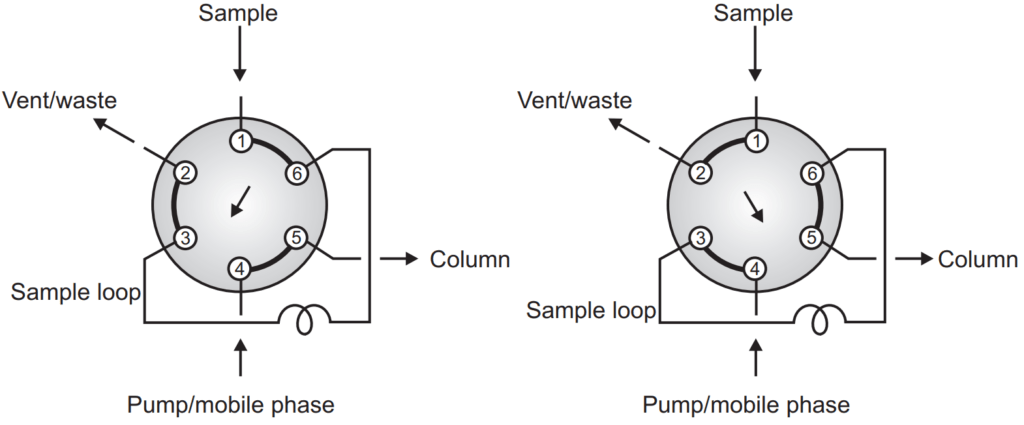

The sample can be introduced into the HPLC by manual method or auto-injection method. It can be septum injection, stop flow (on line) injection, or loop valve (Rheodyne injectors). In septum injection, one rubber septum is used to inject the sample but the septum should withstand to high pressure, and leaching (erosion of rubber) also exists. Sometimes stop the flow of the mobile phase and introduce the sample through a valve device but the most popular is the loop valve (Rheodyne) injector type. In this first sample is loaded on the injector (20- 50 µl) which is the load position and then inject the sample without disturbing the flow of mobile through inject mode.

A very important part of the HPLC is the analytical column but before the analytical column, one guard column is also provided which is comparatively cheaper than the analytical column and helpful to increase the life of the analytical column by removing the entry of unwanted material in the analytical column. The performance of the analytical column decides the efficiency of separation. The column can be made of polyether ketone, stainless steel, polyethylene, or sometimes glass. Stainless steel can be the most widely used column because it can withstand the high pressure compared to the PEER column. The column length can vary from 5-30 cm with a diameter of 2-50 mm using an adsorbent particle size of 1 µm to 20 µm with a uniform spherical porous material. 1gm stationary phase may have an average 400 sqm area.

The detector used in the HPLC can be divided into two categories, the solute property detector, and the bulk property detector. Bulk property detector also known as the universal detector, measure the characteristic of all analyte by analyzing mobile phase without or with a sample. Good examples of these are conductivity detectors or refractive index detectors. Solute property detector corresponds to the particular unique property of the analyte like UV detector, Fluorimetric detector, Photodiode array detector.

The response of the separated constituents can be recorded by the recorder. Recorder amplifies the response which is detected by the detector. It records the time at which the constituent is separated or retention time. The integrator measures the height and width of the peaks, peak area, and percentage of the area.

HPLC can be used for the qualitative analysis by measuring the retention time of the sample under standard conditions but generally, it is used for quantitative analysis by direct comparison method, calibration curve method, and internal standard method.

Make sure you also check our other amazing Article on : Thin Layer Chromatography