Stahl in 1958 developed the standard equipment and technique for analysis by thin-layer chromatography. Before that in 1938 Izmailou and Shraiber separate the phytoconstituent using a 2 mm thick alumina on a glass plate. TLC is a comparatively better separation tool than paper chromatography. Though the adsorbent term uses various times in TLC but the principle of separation may be any one of four fundamental mechanisms of separation:

- Ion exchange

- Partition

- Adsorption

- Molecular exclusion

Principle

The principle of separation totally depends upon the coating substance applied on the plate. If silica or alumina is applied as a coating substance adsorption principle will take place. If the coating substance is Sephadex molecular exclusion will be the principle of separation. Ion exchange will be the mechanism of separation if resin will be the coating substance and cellulose-like coating substance adopt partition mechanism.

The extract of the plant is spotted on the plate and it moves along with the mobile phase. The phytoconstituent of the extract has different affinities towards the stationary phase and mobile phase. Those constituents have more affinity towards mobile phase separation faster compared to those who have more affinity with coating substances.

Silica gel G is one of the most common adsorbents used for the coating of plates. Here G represents the gypsum (CaSO4) which is around 15 percent of the silica gel and acts as a binder. The other adsorbent which is used in the stationary phase is alumina, cellulose, kieselguhr, polyamide powder, and others. Most often the adsorbent are applied on the glass plate. The dimension of the glass plate may vary from 20X20 cm to 20X5 cm. sometimes even microscopic plates are also used to examine the progress of the chemical reaction by the TLC method.

The glasses are coated with adsorbents with different techniques like:

- Pouring,

- Dipping,

- Spraying,

- Spreading techniques.

In the pouring technique, the prepared slurry is poured onto the glass plate and tries to maintain an equal level surface. In the dipping technique, two plates are stick together and dip into the slurry and then remove from the slurry. Separate both plates, one surface will be coated and the other one will be dried. In the spray technique adsorbent is sprayed on a glass plate using a mechanical sprayer. The best applying technique is the spreading technique in which the slurry is kept in the TLC spreader box. The glass plates of a particular size are kept on the base plate. The prepared slurry is kept in the reservoir of the spreader box. Adjust the thickness of the slurry by rotating the knob present in the spreader box then the spreader box is moved over the glass plate. Allow them for air drying and activate them at 100-120°C for one hour.

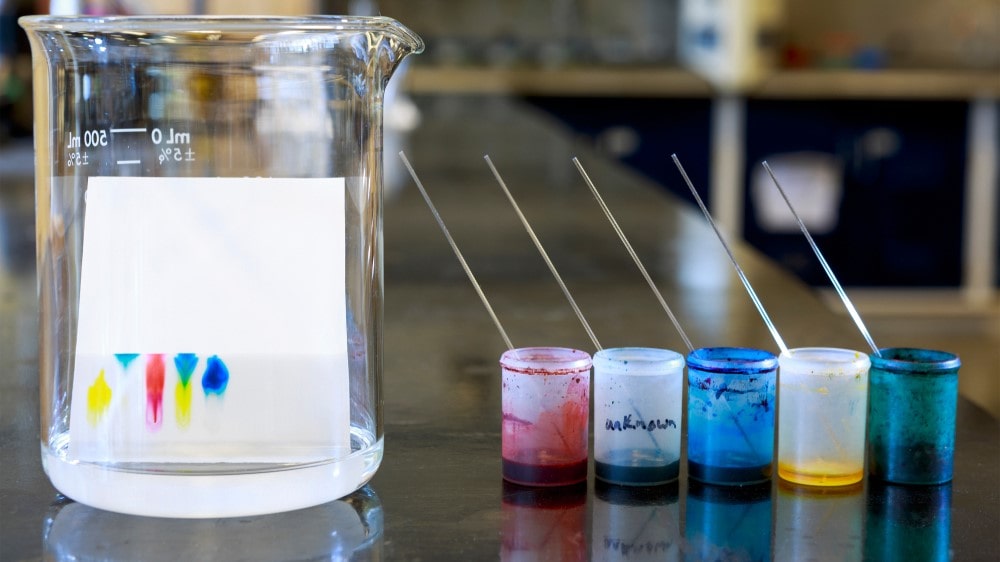

The sample can be applied by micropipette or capillary tube. It should be spotted at least 2 cm above the base of or at such height that the spotted area should not be immersed in the mobile phase. The area of the spotted sample should be minimum with sufficient concentration. The mobile phase and TLC plate should be kept in the development chamber. The chamber should be saturated with mobile phase otherwise edge effect may be found in which the solvent front in the middle of the plate moves faster than the edge. The mobile phase is selected based on the phytoconstituent which has to be separated and the nature of the stationary phase. It may be a single or a mixture of the solvent. The polarity of the solvent was adjusted such that it easily separated the phytoconstituents.

The different development techniques used in the TLC are one-dimensional, two-dimensional, horizontal, and multiple developmental techniques. In one dimensional or vertical technique, the mobile phase flows against the gravity due to the capillary action. Most separations are done by this technique in which one spot is applied at the corner of the plate and the plates are developed in one axis then dried it. Further, turn the plate to 90 degrees and develop the plate on another axis. After the development of the chromatogram, the isolated compound can be visualized by detecting agents. Detecting agents can be two types

- Destructive type

- Non-destructive type.

In the destructive type, the sample cannot be recovered or it will be destroyed due to the chemical reaction of spraying reagent with the sample. While in the non-destructive method sample can be recovered. In the non-destructive method, the sample can be detected by the UV chamber method, densitometric method, or iodine chamber method.

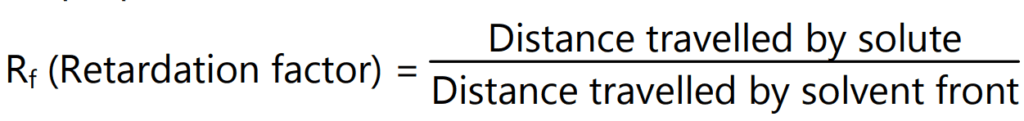

This chromatography can be used for both qualitative and quantitative purposes. For qualitative purposes, The Rf value can be determined.

For quantitative purposes, the density of the spot can be measured or the spot can be eluted with the solvent and analyzed by conventional techniques like spectrophotometric method or electrochemical methods.

Make sure you also check our other amazing Article on : Paper Chromatography