Principle

The cartridge filter is a thin porous membrane in which the pre-filter and membrane filter are combined into a single unit. The filtration action is mainly sieve-like and the particles are retained on the surface.

Construction Cartridge filter

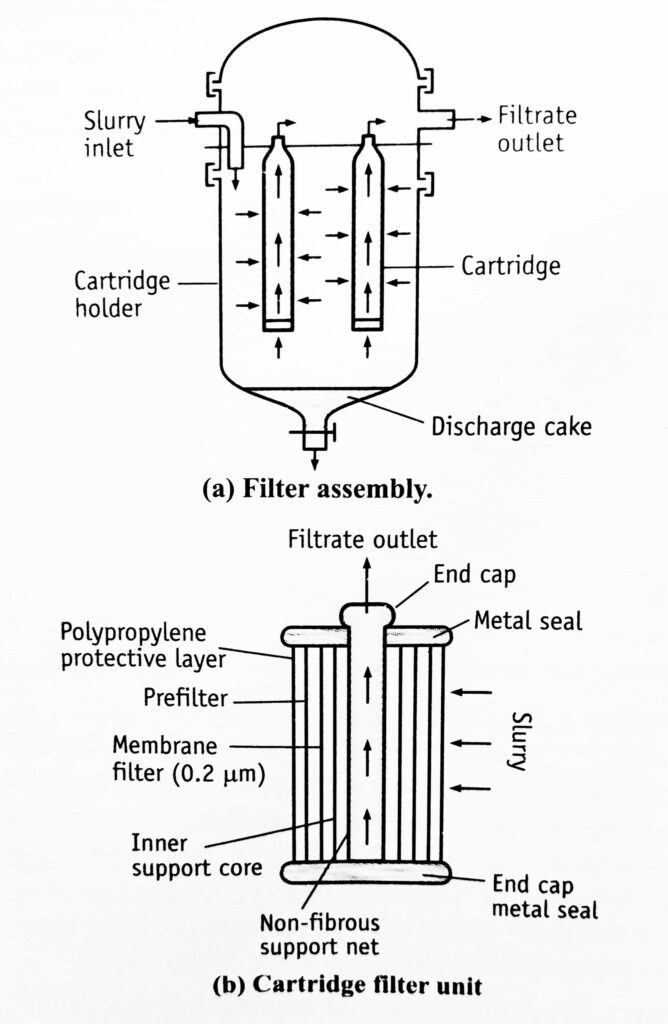

The construction of a cartridge filter is shown in Figure 1.1a. This filter has a cylindrical configuration made with disposable or changeable filter media. These are made of either plastic or metal. It consists of two membrane filters (sieve-like) made of polypropylene: a prefilter and an actual filter for filtration. A protective layer surrounds them. The cartridges are housed in a holder. A number of cartridges can be placed in the same housing. The housing is closed with a lid. The housing has provisions for a slurry inlet and filtrate outlet.

Working

The slurry is pumped into the cartridge holder. It passes through the cartridge filter unit by the mechanism of straining. The clear liquid passes to the center and moves up to collect through the outlet.

Uses: The cartridge filter is particularly useful for the preparation of particulate-free solutions for parenteral and ophthalmic uses. This filter holder will process 1000 to 15000 liters of sterile solution per hour.

Advantages:

- Stainless steel construction permits autoclaving for sterile operations.

- Cartridges with self-cleaning devices are advantageous.

- Rapid disassembling as well as reusing filter media is possible.

- Cartridges are not brittle when they are dry.

- They are used as in-line continuous filtration, which reduces the handling of solutions. It minimizes the chances of contamination.

Disadvantages:

- The cost of disposable elements offsets the labor-saving in terms of assembly and cleaning of cartridge clarifiers.

- A number of manufacturers provided the component, which is generally not interchangeable between suppliers.

Make sure you also check our other amazing Article on : Prevention of Corrosion