The diaphragm pump is classified under the category of reciprocating pumps.

Construction

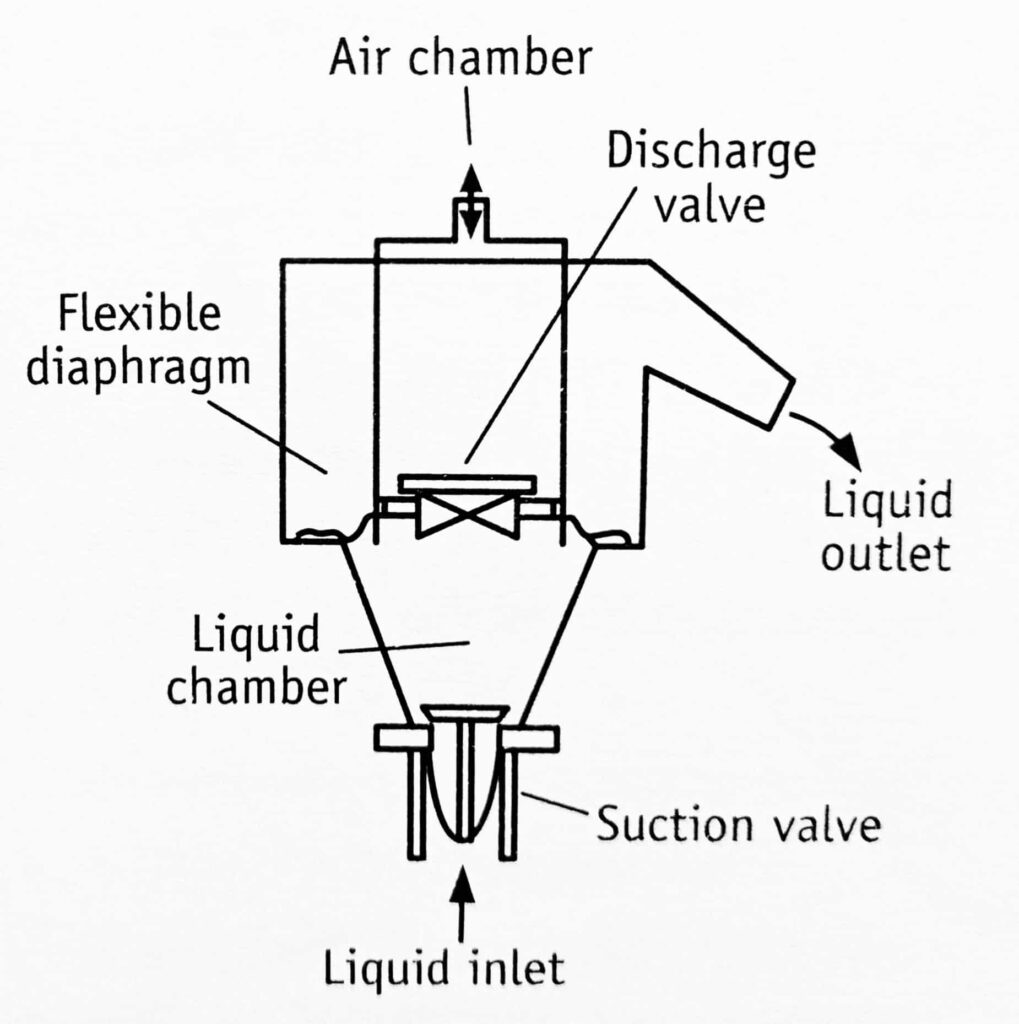

The construction of this pump is shown in Fig. 1.1. It consists of two sections separated by a flexible diaphragm with a flap of discharge valve at the center and the suction valve at the bottom. The diaphragm is fabricated with the materials such as metal, rubber, and plastic.

Working

Through an air chamber, suction is applied so that the flexible diaphragm is pulled up (expanded). As a result, the suction valve is lifted up and the liquid enters the water chamber. When sufficient pressure is built up, the liquid lifts up the discharge valve. Then the liquid flows out. At this stage, suction and discharge valves are opened at the same time. Therefore, non-pulsating discharge is achieved. The stroke can be varied and discharge can be controlled within accurate limits.

Uses of the Diaphragm Pump

Diaphragm pumps are used in transporting liquids containing solids. Hazardous, toxic, and corrosive liquids (Prevention of Corrosion) can also be handled.

Advantages:

- Diaphragm pumps are simple and rugged.

- They can be easily repaired.

- The rate of discharge can be regulated.

- The packing and seals of the diaphragm pump are not exposed to the fluids.

Make sure you also check our other amazing Article on : Difference Between Pipes and Tubes