Difference Between Pipes and Tubes

Pipes

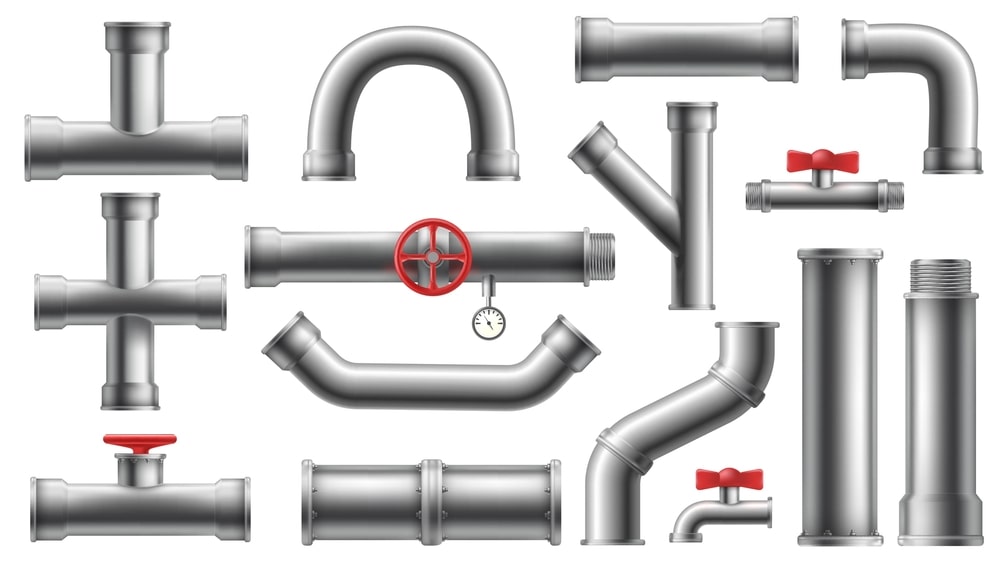

The pipe is a channel through which the fluid flow takes place. Generally, pipes should be clean and smooth from the inside, so that frictional losses and hence pressure head losses can be minimized. These should withstand high temperature and pressure, so that corrosion and hence the formation of rough surfaces can be minimized.

Pipes fabricated from ferrous materials are widely used. These are normally circular in cross-section and available in standard lengths such as 6 to 12 meters (20 to 40 ft). When longer lengths are required, several such lengths are joined together. Pipe standards are specified in terms of thickness of the pipe, pipe threads, outside diameter, etc. In the case of thin-walled pipes, the strength of the pipe is specified in terms of bursting strength (or pressure).

Pipes are referred to as cast iron pipes, steel pipes, iron pipes, wrought iron pipes, etc. Cast iron pipes are normally used for underground lines and for carrying non-corrosive liquids. These are heavier and more expensive than other varieties of pipes. Steel pipes always mean ‘low carbon’ steel pipe. Iron pipes are referred to as pipes made of ‘high carbon steel. Wrought iron pipes are used for a number of special purposes.

Pipes are made from many materials including metals, alloys, wood, ceramics, etc. Pipes can be seamed (jointed) or seamless (joint-less). Seamed pipes are not suitable for handling liquids of high pressure, but these are cheap. Seamless pipes are those pipes that are connected without any visual sign of joining. These are expensive and made by special orders, particularly utilized for high pressures.

Tubes

Nowadays, the ‘tubing word is referred to pipes that are flexible. These are made of plastic, rubber, glass, etc. Tubes are sold on the basis of outside diameter and wall thickness. For long lengths, tubes are joined by fittings made of grey cast iron. In case of serious vibrations, malleable iron fittings are used. These have applications in chemical engineering. The Difference Between Pipes and Tubes are given in Table 1.1.

Difference Between Pipes and Tubes

| Pipes | Tubes |

| Pipes are heavy-walled and supplied straight in large lengths. | Tubes are thin-walled and often supplied as coils. |

| Pipes are available in moderate lengths, 6 to 12 meters (20 feet to 40 feet). | Tubes are available several meters long. |

| Pipes are usually threaded. | Tubes do not have threads, particularly plastic or rubber. |

| The walls of the pipes are rough. | The walls of the tubes are smooth. |

| More expensive. | Relatively cheap. Polyvinyl chloride tube is used extensively for water lines. |

| Used in chemical industries and special purposes. | Tubes are made usually by extrusion or cold drawing. |

| Pipes are manufactured by welding, casting, or piercing a billet in a piercing mill. | Tubes are joined by soldering, compression, or false fillings. |

| Pipes are joined usually by screwed fitting, flanges, or welding. |

Make sure you also check our other amazing Article on : Rotameter