Table of Contents

Principle

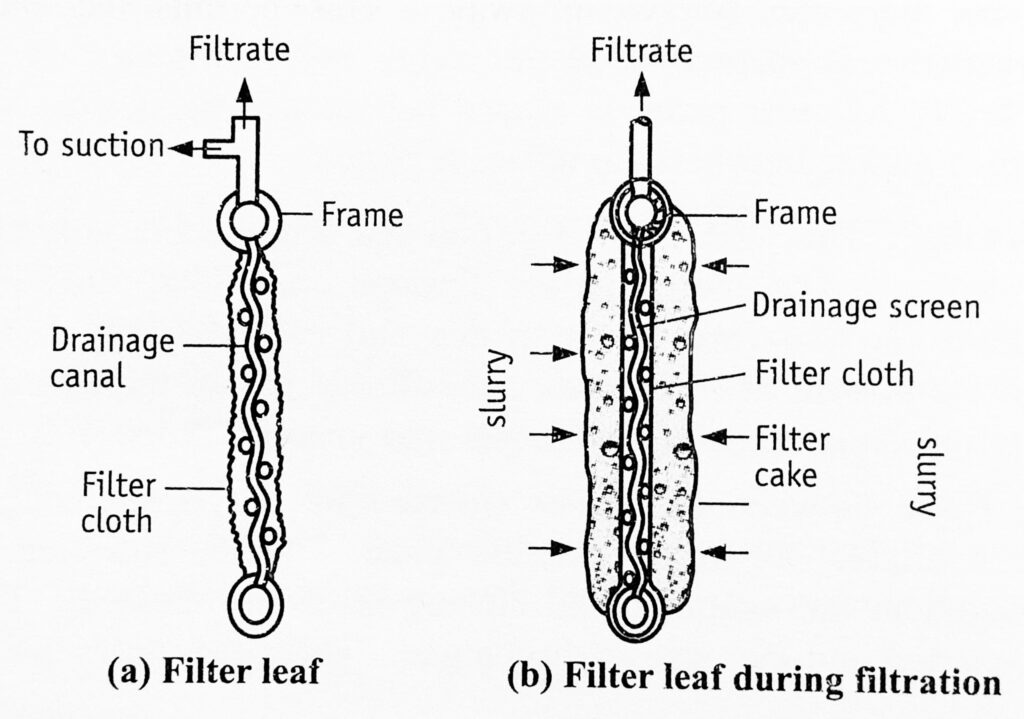

A filter leaf is an apparatus consisting of a longitudinal drainage screen covered with a cloth. The mechanism is surface filtration and acts as a sieve or strainer. Vacuum or pressure can be applied to increase the rate of filtration.

Construction

The general arrangement of a filter leaf is shown in Figure 1.1. It consists of a narrow frame enclosing a drainage screen or grooved plate. The frame may be of any shape, circular, square, or rectangular. The whole unit is covered with a filter cloth. The outlet for the filtrate connects to the interior of the frame through suction.

Working

The filter leaf is immersed in the slurry. The vacuum system is connected to the filtrate outlet. The slurry passes through the filter cloth. Finally, filtrate enters the drainage canal and goes through the outlet into the receiver. Air is passed to flow in the reverse direction which facilitates the removal of cake.

Uses: The filter leaf is satisfactory, if the solid content of the slurry is not too high, about 5%, i.e., dilute suspensions.

Advantages:

- Filter leaf is a versatile piece of equipment. Filter leaf is probably the simplest form of filter used for batch processes.

- A number of units can be connected in parallel to increase the surface area for filtration.

- The pressure difference can be obtained either with vacuum or using pressure up to the order of 800 kilopascals.

- Labor costs for operating the filter leaf are fairly moderate.

- The efficiency of washing is high.

- The slurry can be filtered from any vessel. Simply immersing the filter in a vessel of water can wash the cake.

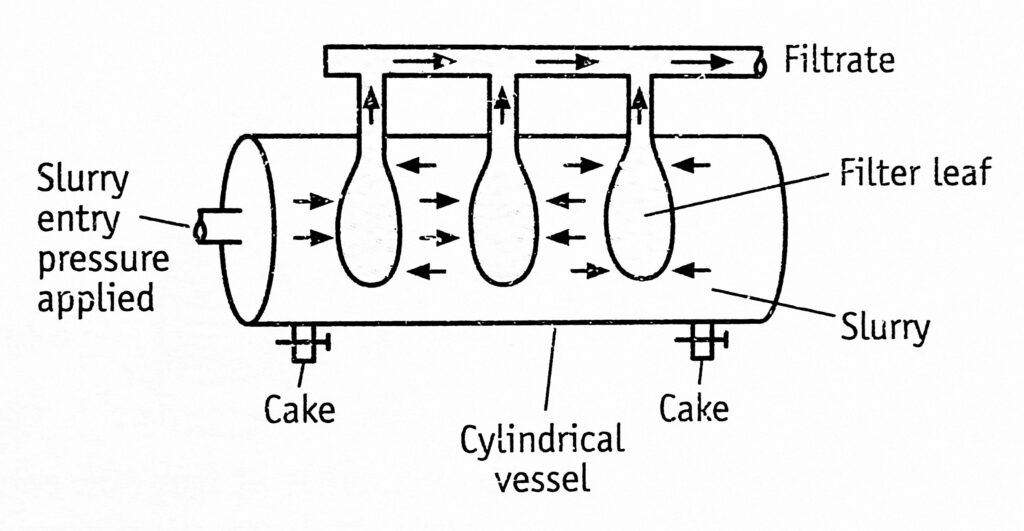

Variants: Sweetland filter: A variation is to enclose the filter leaf in a special vessel into which the slurry is pumped under pressure. In this form, a number of leaves are connected to a common outlet to provide a large area for filtration. A typical example of this kind is the Sweetland filter shown in Figure 1.2. The vessel is cylindrical and filter leaves are arranged so that they are supported by the upper part.

The lower part can be swung away. This permits the cake to be discharged by compressed air while removing the filter leaves from the vessel.

Make sure you also check our other amazing Article on : Plate and Frame filter press