Table of Contents

Principle

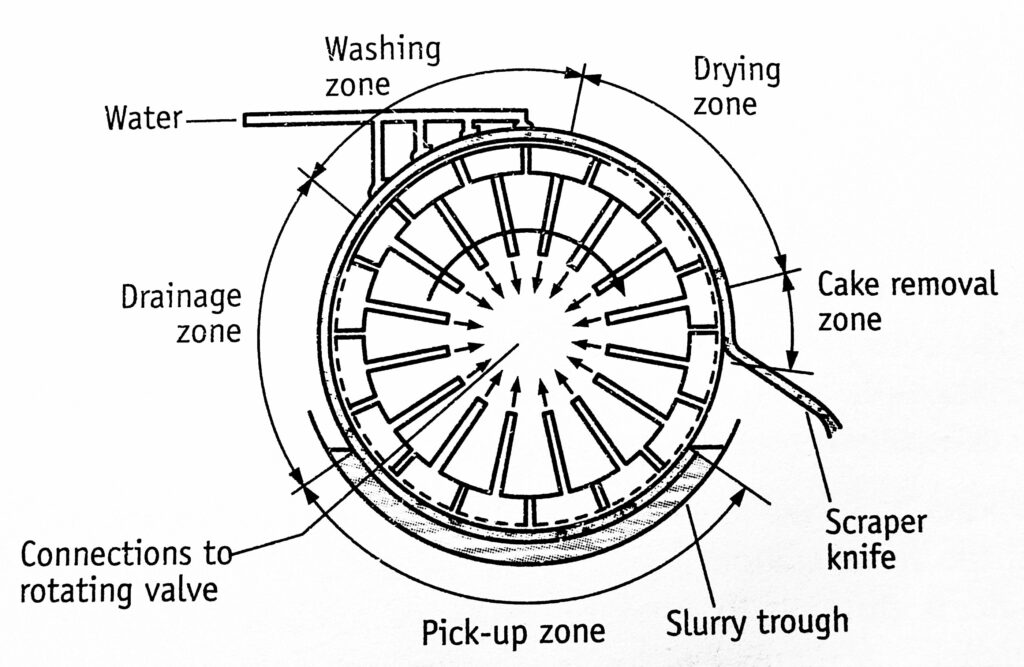

Rotary drum filter functions on the principle of filtering the slurry through a sieve-like mechanism on a rotating drum surface, under the conditions of vacuum. In addition, compression, drying (using hot air) and removing the filter cake (using a knife) are possible.

Construction

The construction of a rotary drum filter is shown in Figure 1. It consists of a metal cylinder mounted horizontally. The drum may be up to 3 metres in diameter and 3.5 metres in length and gives a surface area of 20 metres square. The curved surface is a perforated plate, which supports a filter cloth. The drum is radially partitioned dividing the annular space into separate compartments. Each of them is connected by an internal pipe to the centre of the drum through a rotating valve.

Working

The drum is rotated at a speed of less than one revolution per minute. The drum just enters the slurry in the trough (Figure 1). As it dips, a vacuum is applied in this segment so that the solid is built upon the surface. The liquid passes through the filter cloth into an internal pipe and valve. Finally, the filtrate reaches the collecting tank.

As the drum leaves the slurry section, it enters the drainage zone. Here excess of the liquid is drawn inside. Special cake compression rollers may be included at this stage so that the cake is consolidated by the compression of the cake. This improves the efficiency of the washing and drying process.

- A vacuum is applied to carry the slurry along with the drum

- Drainage zone

- Water washing arrangement > Drying zone dry air supply

- Cake removal zone

As the drum leaves the drainage zone, it enters the water wash section. Water is sprayed on the cake. A separate system of vacuum is applied on the panel in order to suck the wash liquid and air through the cake of solids. Wash liquid is drawn through the filter into a separate collecting tank.

Then the cake enters the drying zone, where hot air is blown on the cake. The cake may have a moisture content of less than one per cent. Finally, the cake is removed using a doctor’s knife and discharged.

All these steps are completed in one rotation of the drum. Now the drum is ready to receive a fresh lot of slurry.

Uses

The drum filter is used for continuous operation and is utilised to filter slurries containing a high proportion of solids up to 15 to 30 per cent. In the production of penicillins, the extract is separated from mycelium (cell mass) by drum filters. These are used for collecting calcium carbonate, starch and magnesium carbonate.

Advantages of Rotary Drum Filter

- The cake is removed simultaneously during operation. Therefore, suitable for use with concentrated slurries.

- The labour costs are very low on account of the automatic and continuous operation of the rotary filter.

- The filter has a large surface area.

- The speed of rotation can be varied and the cake thickness can be controlled. For example, if the solids form an impenetrable cake, the thickness may be limited to less than 5 millimetres. On the other hand, if the solids are coarse and form a porous cake, a thickness of 100 millimetres or more, can be obtained.

Disadvantages of Rotary Drum Filter

- A rotary drum filter is expensive equipment with complex functioning. It contains moving parts and also requires a number of accessories such as vacuum pumps, vacuum receivers, traps etc.

- The cake tends to crack due to the air drawn through by the vacuum system. This makes washing and drying processes inefficient.

- The rotary filter is suitable only for straightforward slurries. It is less satisfactory if the solids form an impermeable cake or if it is difficult to remove the cake adequately.

Variants: String discharge rotary filter: It is especially used for filtering the fermentation liquor in the manufacture of antibiotics, where the mould is difficult to filter by ordinary methods because it forms a felt-like cake. A number of loops of string are kept on the drum surface, which passes around the drum. The cake is formed on the strings. These strings lift the filter cake off the filter medium and are thus removed.

Make sure you also check our other amazing Article on : Filter Leaf