Principle

In a horizontal tube evaporator, steam is passed through the horizontal tubes, which are immersed in a pool of liquid to be evaporated. Heat transfer takes place through the tubes and the liquid outside the tubes gets heated. The solvent evaporates and escapes from the top of the evaporator. The concentrated liquid is collected from the bottom.

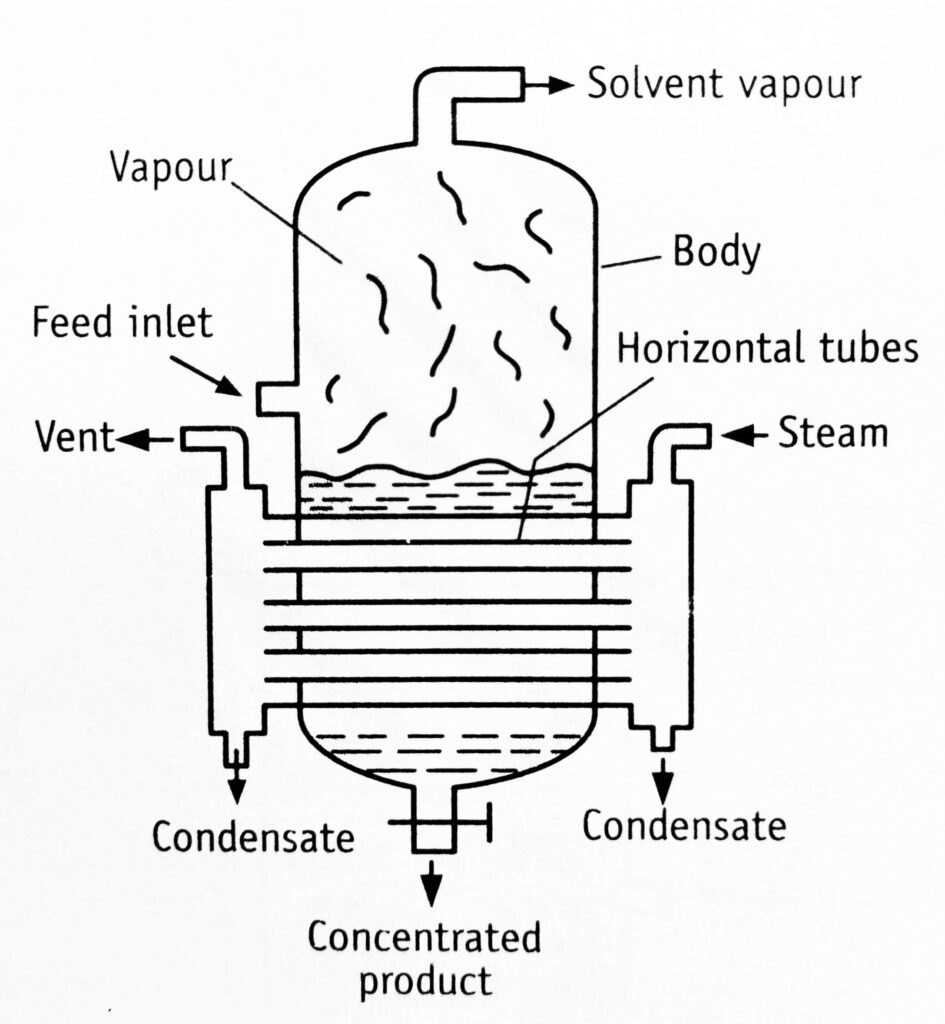

Construction of the horizontal tube evaporator

The construction of a horizontal tube evaporator is shown in Figure 1.1. It consists of a large cylindrical body with a conical or dome-shaped top and bottom. It is made up of cast iron or plate steel. The average size of the body ranges from 1.8 to 2.4 metres in diameter and from 2.4 to 3.6 metres in height.

The lower part of the body consists of a steam compartment with an inlet for steam at one end and a vent for noncondensed gases on the other end. A condensate outlet is provided at the bottom of the steam compartment. In the steam compartment, 6-8 stainless steel horizontal tubes are placed. The tubes are cut long enough so that they project about 25.0 millimetres beyond the tube sheet on both ends. The width of the steam compartment is usually half the diameter of the body.

At one convenient point, an inlet for feed is provided (Figure 1.1). One outlet for vapour is placed at the top of the dome. Another outlet for thick liquid is placed at the centre of the conical bottom of the body.

Working on horizontal tube evaporator

The feed is introduced into the evaporator until the steam compartment is satisfactorily immersed. Steam is introduced into the steam compartment. The horizontal tubes receive heat from the steam and conduct it to the liquid due to the temperature gradient. Steam condensate passes through the corresponding outlet. The feed absorbs heat and the solvent gets evaporated. The vapour then escapes through the outlet placed at the top. This process is continued until a thick liquid is formed, which can be collected from the bottom outlet.

Uses: It is best suited for non-viscous solutions that do not deposit scales or crystals on evaporation, for example, cascara extract.

Advantage: The cost per square metre of the heating surface is usually less in a horizontal tube evaporator.

Make sure you also check our other amazing Article on : Microwave Dryer