Principle

The liquids to be mixed are pumped separately into a jet mixer at different velocities. The high-velocity fluid has a lower static pressure than the surrounding liquid (higher static pressure). During mixing. the slow-moving liquid will be drawn into the high-velocity jet. This increases the volume of the jet and decreases velocity, which causes the jet to expand. Thus shear is developed and aids in mixing.

Working

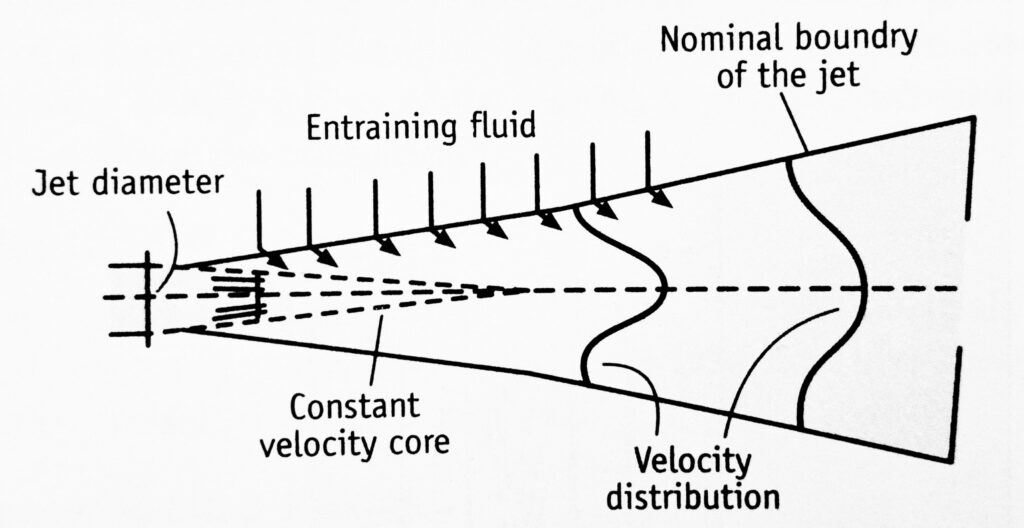

The construction of a jet mixer is shown below the figure. Two liquids are introduced into the mixing tank at different velocities One liquid is pumped through a small nozzle at a uniform high velocity The second liquid enters the tank at a low velocity. The fast-moving liquid impinges on the slow-moving liquid at high velocity. As the jet moves away from the orifice, the area of its influence decreases. The core of the jet is surrounded by an expanding turbulent jet, in which the radial velocity decreases with distance from the center-line of the jet.

When a rapidly moving liquid comes in contact with a slow-moving (or almost stationary) liquid, the high-velocity gradient will be developed at the boundary. As a result, strong shear stresses exist at the boundary. which induces mixing in two ways.

- The stresses tear off portions of the fast-moving stream and send it off into the slower moving areas as vortexes or eddies. The shear stresses tear-off eddies and generates considerable turbulence, which contributes to the mixing action.

- When a slow-moving liquid enters the jet, the volume of the jet increases, and velocity decreases. This decreasing velocity causes the jet to expand. Thus shear develops which aids in mixing Enough time and space must be provided for the stream to blend thoroughly into the mass of fluid by the mechanism of entrainment.

Advantage: The power required for pumping is often sufficient to accomplish the mixing operation.

Make sure you also check our other amazing Article on : Scrubbers