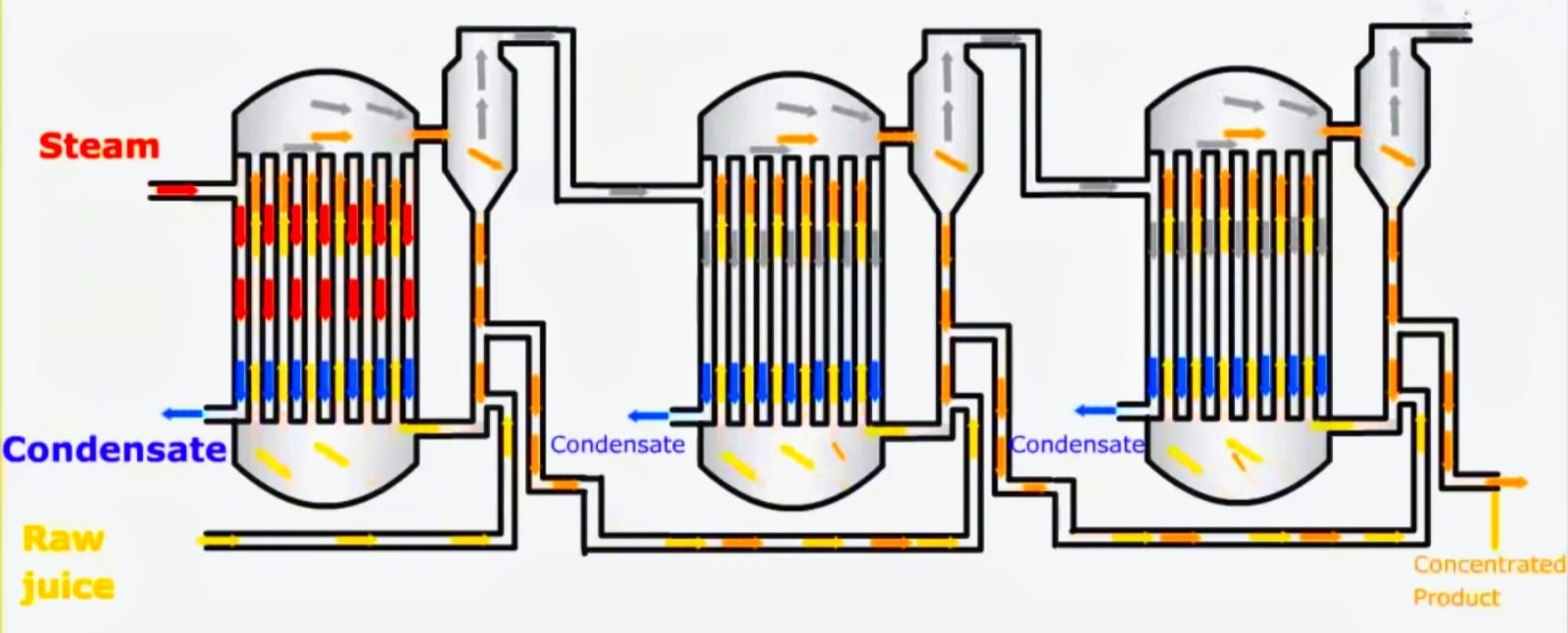

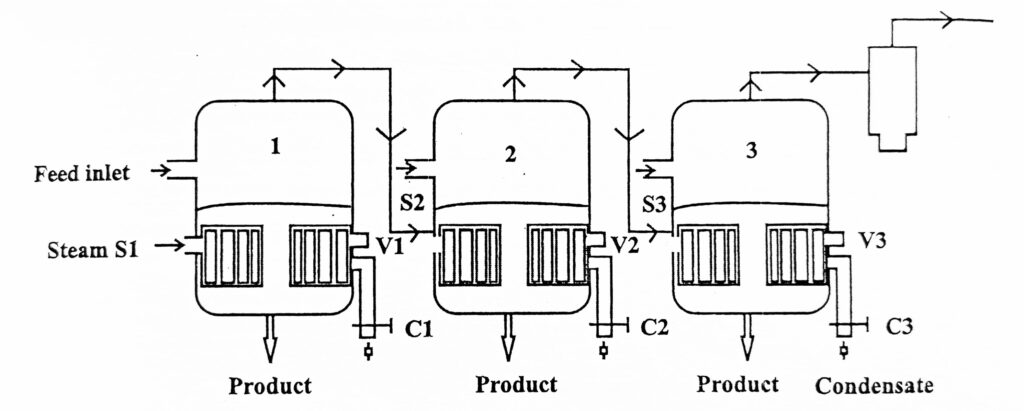

It is the modification of a single-effect evaporator. A single-effect evaporator wastes energy. The latent heat of the vapor is not used but discarded. However, much of this latent heat can be recovered and reused by employing a multi-effect evaporator. It consists of three evaporators therefore it is also called the triple evaporator or Multiple Effect Evaporator. The vapor from the first evaporator.

Construction

serves as the heating medium for the second evaporator. Similarly, vapor from the second evaporator serves as a heating medium for the third evaporator. The third evaporator is connected to a vacuum pump.

Working on Multiple Effect Evaporator

In this method, the feed (hot liquid solution) is introduced into the three evaporators. The parallel feed arrangement method is used. The vent valves V1, V2, and V3 are kept open. Now, a high vacuum is created by starting the vacuum pump. The steam valves S1 are open through which steam is supplied. The steam first replaces the cold air in the vapor space of the 1st evaporator. When all the cold air is removed, the V11 valves are closed. The condensate valves are also open. The steam supply continues until the desired pressure Po is reached in the steam space of the first evaporator. At this pressure, the temperature of the steam is noted too. The steam gets condensed and the condensate is discharged through valve Cl. Due to the heat transfer, the temperature rises, and the liquids reach the boiling point. During this process, the vapor is generated. The vapor formed displaces the air in the upper part of the 1st evaporator. After the complete displacement of the air by the vapor in the steam compartments of the second evaporator, valve V2 is closed.

The vapor of the 1st evaporator transmits its heat to the liquids of the 2nd evaporator and condensed, the condensate is evacuated by valve C2. These steps continue in the 3rd evaporator also.

As the liquid in the 1″, evaporator gains temperature, the temperature difference between the liquids and the vapor decreases, so the rate of condensation decreases. As a result, the pressure in the vapor space of the 1″ evaporators increases gradually to P, and the rising temperature is noted as t, which is the boiling point of the liquids in the evaporator 1″ and decreases the temperature difference (to-t₁).

A similar change takes place in the 2nd evaporator and the liquids reach the boiling point. Similarly, the process will be repeated in the 3d evaporators. Finally, three evaporators reach to steady-state with the liquid boiling in all three bodies.

As boiling progresses, the liquid level in the 1″ evaporator decreases. The feed is fed through the feed valve to keep the fluid level constant. Similarly, the evaporation of liquids takes place in the 2 and 3d evaporators. To maintain the constant liquid level, the feed valves F2 and F3 are used for the second and third evaporators respectively. This process is continued until the evaporators reach the desired viscosity.

Now the product valves are open to collect the thick liquid. Thus, in this evaporator, there is a continuous feed system as well as a continuous supply of steam and a continuous withdrawal of the liquid from the three evaporators. As a result, the evaporators operate continuously with all the temperature and pressure in equilibrium.

There are also different feed arrangements such as forward feed arrangements, backward feed arrangements, and mixed feed arrangements.

In forward feed arrangement, feed is introduced from 1″ Evaporators to 2 evaporators to 3 evaporators. Pumping is not required because the feed is automatically moved from high pressure to a low-pressure evaporator. This method is also suitable for scale-forming liquids. But this method is not suitable for cold feed.

In backward feed, the arrangement is reverse of a forwarding feed arrangement (Le from 3d evaporator and then to 1″ evaporator). This type of arrangement is suitable for cold feed and viscous preparations. But in this case, pumping is required as the liquid is moving from low pressure to the high-pressure evaporator.

In a mixed feed arrangement, feed enters into a 2d evaporator and then goes to 3 and 1″ evaporators.

Use: This is suitable for scale-forming liquids.

Advantages

- It is suitable for continuous operation.

- It is economical when compared with a single effect evaporator.

- The product is obtained at the lowest temperature.

Disadvantage

- It is not suitable for cold feed

Make sure you also check our other amazing Article on : Forced Circulation Evaporator