Table of Contents

Principle

In a forced circulation evaporator, the liquid is circulated through the tubes at high pressures by means of a pump. Hence, boiling does not take place because the boiling point is elevated. Forced circulation of the liquid also creates some form of agitation. When the liquid leaves the tubes and enters the vapour head, the pressure falls suddenly. This leads to the flashing of superheated liquor. Thus evaporation is affected.

Construction

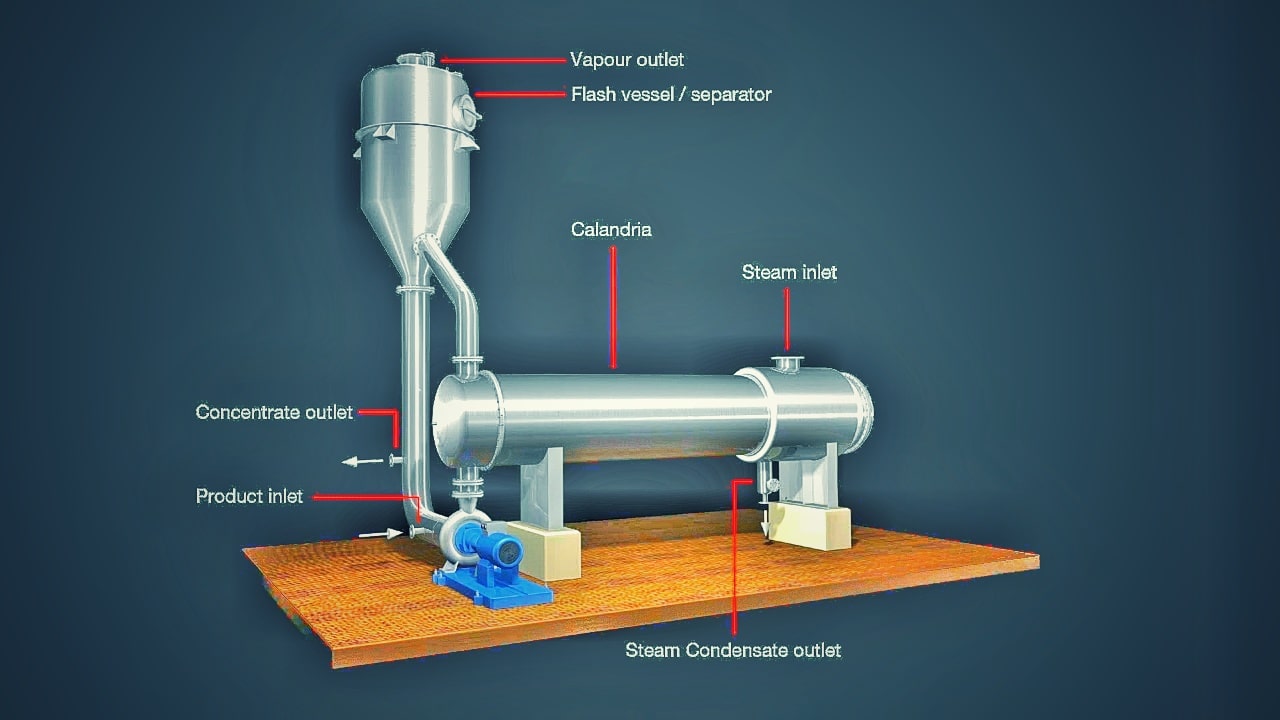

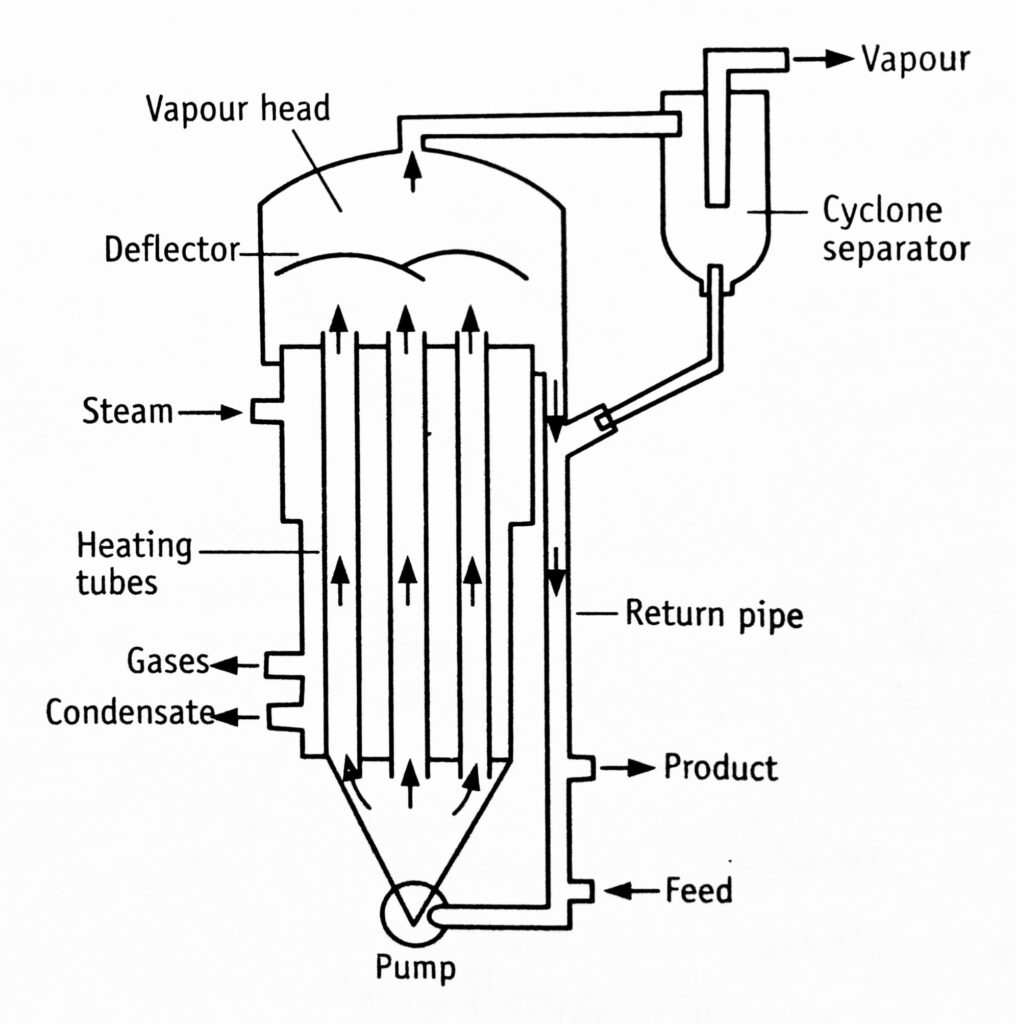

The construction of a forced circulation evaporator is shown in Figure 1.1. The steam jacketed tubes are held between two tube sheets. The tube measures 0.1 metres in diameter and 2.5 metres long. The part of the tubes projects into the vapour head (flash chamber), which consists of a deflector. The vapour head is connected to a return pipe, which runs downwards and enters into the inlet of a pump.

Working on forced circulation evaporator

Steam is introduced into calandria. The pump sends the liquid to the tubes with a positive velocity. As the liquid moves up through the tubes, it gets heated and begins to boil. As a result, the vapour and liquid mixture rushes out of the tubes at a high velocity. This mixture strikes the deflector, which throws the liquid downward. This results in an effective separation of liquid and vapour. The vapour enters the cyclone separator and leaves the equipment. The concentrated liquid returns to the pump for further evaporation. Finally, the concentrated product is collected.

Uses: If evaporation is conducted under reduced pressure, a forced circulation evaporator is suitable for thermolabile substances. This method is used for the concentration of insulin and liver extracts. It is well suited for crystallizing operations where crystals are to be suspended at all times.

Advantages

- In this evaporator, the heat transfer coefficient is high due to rapid liquid movement.

- Salting, scaling, and fouling are not possible due to forced circulation.

- This evaporator is suitable for thermolabile substances because of its rapid evaporation.

- It is suitable for high viscous preparations because the pumping mechanism is used.

Disadvantages: In a forced circulation evaporator, the hold-up of liquid is high. The equipment is expensive because power (pump) is required for circulating the liquid.

Make sure you also check our other amazing Article on : Falling Film Evaporator