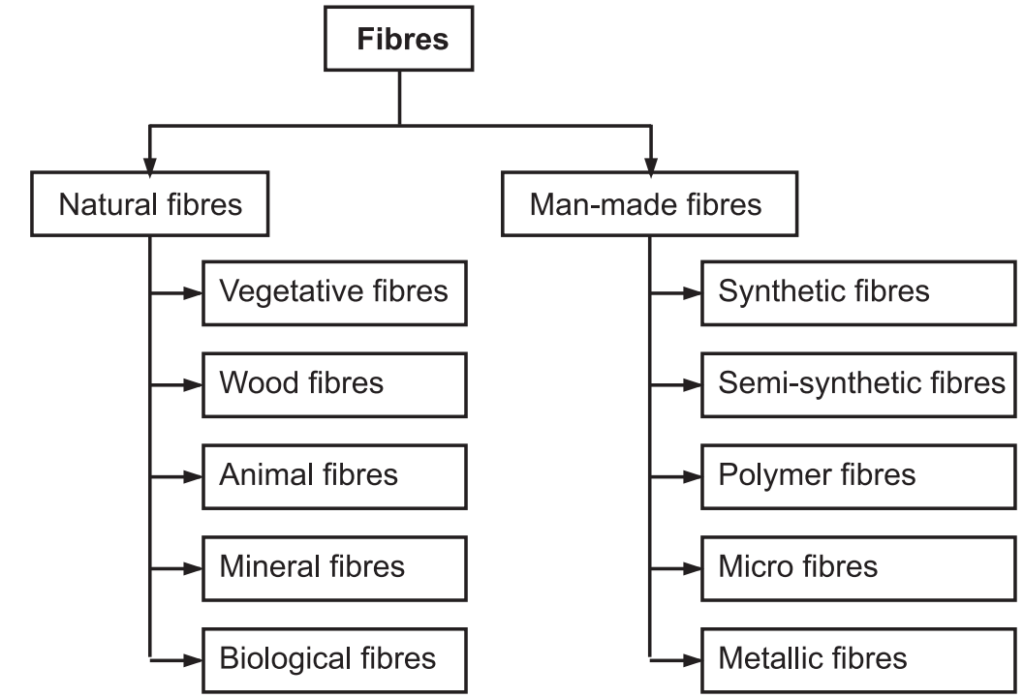

Plant Fibres are natural or synthetic strings. They are used as a component of composite materials. In alternate, fibres are threads or filaments from which a vegetable tissue, mineral substance or textile is formed. By textile word, fibres are defined as a unit of matter characterized by flexibility, fineness and a high ratio of length to thickness. Depending on the sources, fibres are classified broadly into two categories (Fig. 1.1).

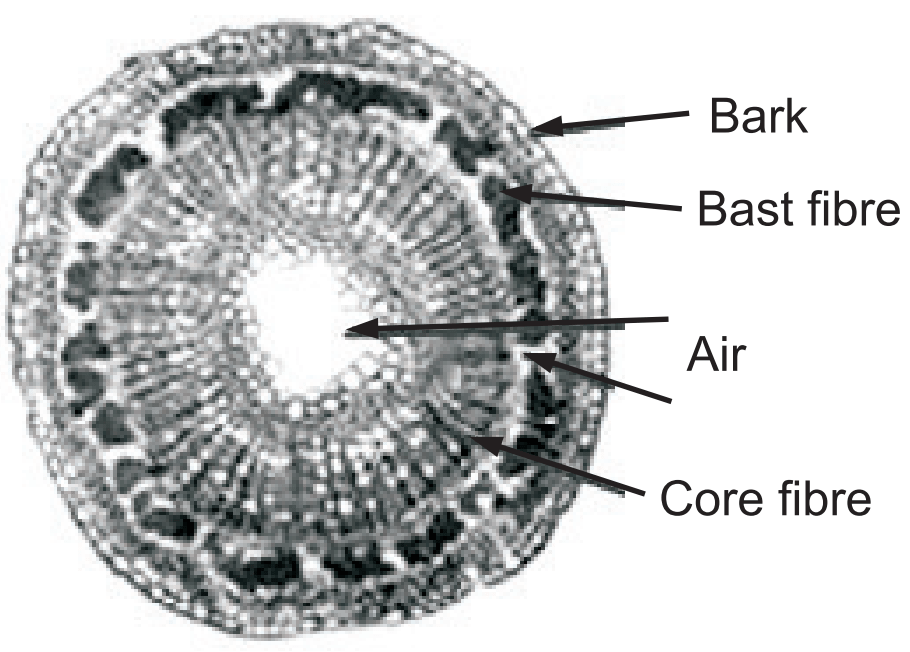

Vegetable Fibres or Bast Fibres: They are also known as skin fibres. They are collected from the phloem (the “inner bark” or the skin) or bast surrounding the stem of certain plants i.e., mainly dicotyledonous plants. They support the conductive cells of the phloem and provide strength to the stem. They are separated from the xylem by the retting method by treating with microorganisms either on land or in water or by chemicals or by pectinolytic enzymes. They are generally based on arrangements of cellulose, often with lignin. They have higher tensile strength. Examples include cotton, hemp, jute, flax, banana, sisal etc. They are employed in the manufacture of various ropes, yarn, in the paper and textile industries. Dietary fibres are important for human nutrition as they are used as laxatives (Fig. 1.2).

Bast fibres from the stem: Examples: Flax, Hemp, Jute etc.

Bast fibres from leaf: Examples: Ananas, Agave, Palm etc.

Bast fibres from seed: Examples: Cotton, Soya, Coir etc.

Bast fibres from fruit: Examples: Luffa, Coir etc.

Bast fibres from grass: Examples: Bamboo, Totora etc.

Bast fibres from wood: Examples: Hardwood, Softwood etc.

Wood fibres: They are usually cellulose elements that are extracted from trees and are used to make materials including paper. There are different forms of wood fibres including groundwood, thermomechanical pulp and bleached or unbleached sulfite pulps. Sulfite pulp is obtained by a pulping process that is used to remove the lignin bonding the original wood structure.

Animal fibres: They are obtained from different parts of animals and consist largely of particular proteins. Examples: Silkworm silk, catgut, wool; Hair such as cashmere wool, mohair and angora; Fur such as sheepskin, rabbit, mink etc.

Mineral fibres: They include the asbestos group and are long fibres. Six minerals have been classified as “asbestos” including chrysotile, amosite, crocidolite, tremolite, anthophyllite and actinolite. Short mineral fibres are wollastonite, palygorskite etc.

Biological fibres: They are also known as fibrous proteins. They consist of biologically important proteins, mutations etc. Examples: Collagen, actin.

Synthetic fibres: They are man-made fibres derived from natural fibres, mainly cellulose, e.g., nylon and terylene. Nylons are polymers of adipic acid and hexamethyl diamine, whereas terylene is a polymer of ethylene glycol and terephthalic acid.

Semi-synthetic fibres: Semi-synthetic fibres are made from raw materials with naturally long-chain polymer structure and are only modified and partially degraded by chemical processes. Generally, they are regenerated cellulose derivatives. Examples: Rayon, bamboo fibres etc.

Polymer fibres: They are based on synthetic chemicals and made from polyamide nylon, polyester, polyvinyl chloride etc.

Microfibres: They are ultra-fine fibres often used in filtration. In textiles, microfibres are referred to as sub-denier fibres.

Metallic fibres: These fibres are prepared from the metals such as copper, gold or silver and extruded or deposited from more brittle ones such as nickel, aluminium or iron.

Table of Contents

Differences between Natural Fibres and Synthetic Fibres

- Natural fibres are derived from plants and animals, whereas synthetic fibres are almost entirely man-made.

- Fabrics made of natural fibres are generally more comfortable than synthetic ones.

- Natural fibres are expensive compared to synthetic fibres.

- In synthetic fibres, spinnerets are used to produce the filaments; whereas, in natural fibres, it is made naturally.

- Natural fibres have limited usage when compared to synthetic fibres.

- Natural fibres are biodegradable, hence environmental friendly, whereas synthetic fibres are not.

Differences between Plant and Animal Fibres

- On ignition, animal fibres give a bad smell; whereas plant fibres do not give a smell.

- Plant fibres are soluble in cuoxam solution (ammoniacal copper oxide), whereas animal fibres are 50% soluble in alkaline hydroxide solution.

- Plant fibres form blue colour when reacted with iodine in the presence of dilute sulphuric acid; whereas animal fibres form a permanent yellow stain when reacted with picric acid.

- Plant fibres react with Molish’s reagent to form violet colour; whereas with Millon’s reagent, animal fibres give red stain.

Cotton

Biological source: Cotton is a natural source of fibres consisting of the hairs of the seeds of Gossypium species like Gossypium hirsutum L., G. barbadense L and G. herbaceum.

Family: Malvaceae.

Distribution: The plant is a shrub native to tropical and subtropical regions around the world, including America, Africa, Australia and India. Gossypium hirsutum is native to Central America, the Caribbean and southern Florida, G. barbadense is native to tropical South America, G. arboreum is native to India and Pakistan. In India, the major production of the plant is in Maharashtra, Gujarat, Punjab, Andhra Pradesh and Madhya Pradesh.

Description of the plant: The plant is perennial and annual and about 6 to 12 feet tall. Underground, the cotton plant develops a strong taproot with many lateral branches, penetrating as deeply as 8 to 10 feet. The leaves are heart-shaped with pointed lobes. There are three to five lobes at the ends of each leaf blade, which measures up to 7 inches long and across. Leaves are fuzzy and are arranged in an alternating pattern on the stems and branches. The flowers are five-petaled and creamy white or yellow in colour. After pollination, the three- to four-chambered ovary inside ripens to form a green capsule or “boll.” This long, spherical capsule contains a few oil glands as well as many dark brown seeds that are encased in lint and fuzz. The capsule contains numerous seeds (Fig. 1.3).

Preparation of Cotton: A fertilized flower takes about 20-45 days to become an open boll. After the plant flowers, the cotton fibres (lint) develop on the seed in the boll in three stages. In the “elongation” stage (0 to 27 days), the fibre cell develops a thin, expandable primary wall surrounding a large vacuole. During the “thickening” stage (15 to 55 days), the living protoplast shrinks, while a secondary wall composed almost entirely of cellulose is deposited inside the primary wall. By the “maturation” stage, the secondary wall fills most of the fibre cell volume, leaving a small central cavity (the lumen) containing the cytoplasm and the vacuole. As the boll opens, the fibre cells rapidly desiccate, collapse and die. As the tubular cells collapse, they assume a flat, ribbon-like form with twists, called “convolutions.” The fibre removed from the plant also contains the cotton seeds and is referred to as “seed cotton.” The harvested seed cotton is transported to the gin. Ginning is the process of separating cotton fibres from the seeds. Seed cotton are then cleaned with dilute soda solution under pressure for several hours to remove the impurities like wax, fatty matters and finally treated with a suitable bleaching agent and then packed for transportation.

Three broad types of cotton are generally recognized on the basis of the length, strength and structure of the fibre.

- Long Staple Cotton: It has the longest fibre whose length varies from 24 to 27 mm. The fibre is long, fine and shiny. It is used for making fine and superior quality cloth. It is largely grown in Punjab, Haryana, Maharashtra, Tamil Nadu, Madhya Pradesh, Gujarat and Andhra Pradesh.

- Medium Staple Cotton: The length of its fibre is between 20 mm and 24 mm. About 44% of the total cotton production in India is of the medium staple. Rajasthan, Punjab, Tamil Nadu, Madhya Pradesh, Uttar Pradesh, Karnataka and Maharashtra are its main producers.

- Short Staple Cotton: This is inferior cotton with fibre less than 20 mm long. It is used for manufacturing inferior cloth. It is grown in U.P., Andhra Pradesh, Rajasthan, Haryana and Punjab.

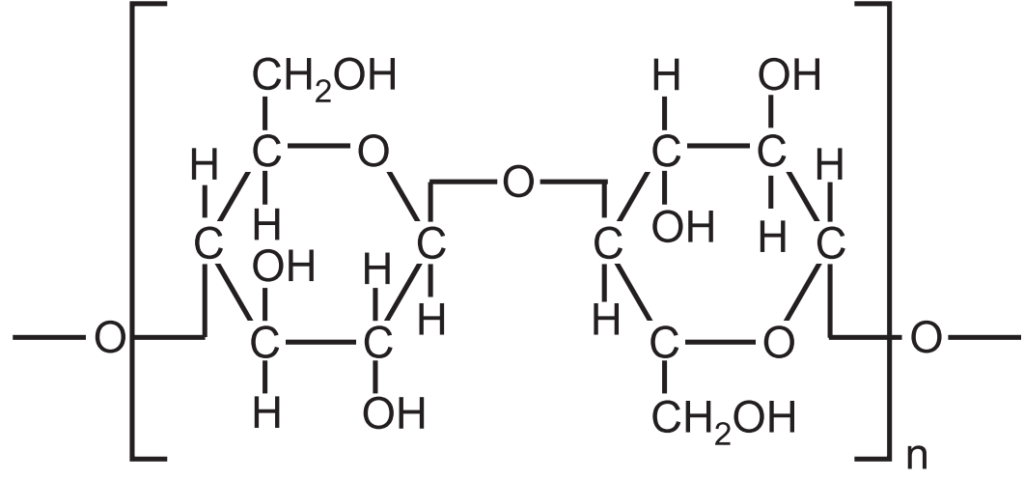

Chemical Constituents: Cotton mainly contains cellulose, moisture, protein, ash, pectin, oil, fat and some pigments. The whole cotton fibre contains 88 to 96.5% of cellulose (Fig. 1.4), the rest are non-cellulosic polysaccharides constituting up to 10% of the total fibre weight.

non-cellulosic constituents consist of pectins, fats and waxes, proteins and natural colourants. The secondary wall contains about 92-95% cellulose and 8-9% moisture.

Chemical Tests:

- Cotton fibres are soaked in iodine water and then 80% sulphuric acid is added. The trichomes become bluish-green in colour.

- Raw cotton fibres dissolve in cuoxam solution and form a balloon-like structure, whereas absorbent cotton dissolves completely and swells in the same solution.

Cotton fibres Use:

The long cotton fibres are used to make cloth and the short fibres are used in the paper industry. Further in the pharmaceutical field, cotton is used as filter media and various surgical dressings. It is also used as an insulating material.

Storage: Cotton in wrapped condition, is stored in a cool place with a dustproof cupboard.

Jute

Biological Source: The jute fibre is collected from the stem bark of the white jute plant and to a lesser extent Tossa jute belongs to species Corchorus i.e. C. capsularis and C. olitorius.

Family: Tiliaceae or Malvaceae.

Distribution: Jute is cultivated in Bangladesh, Nepal, Myanmar, India, Thailand, China, Pakistan, Japan, UK, France, Egypt and Spain. In India, the major production of jute is in West Bengal, Assam and Bihar.

Description of Plant: The plants are annual herbs with 2-4 m in height. They are unbranched or with a few side branches. The leaves are alternate, simple and lanceolate in shape (Fig. 1.5). They are 5-15 cm long, with an acuminate tip and a finely serrated or lobed margin. The flowers are 2-3 cm in diameter and are yellow in colour.

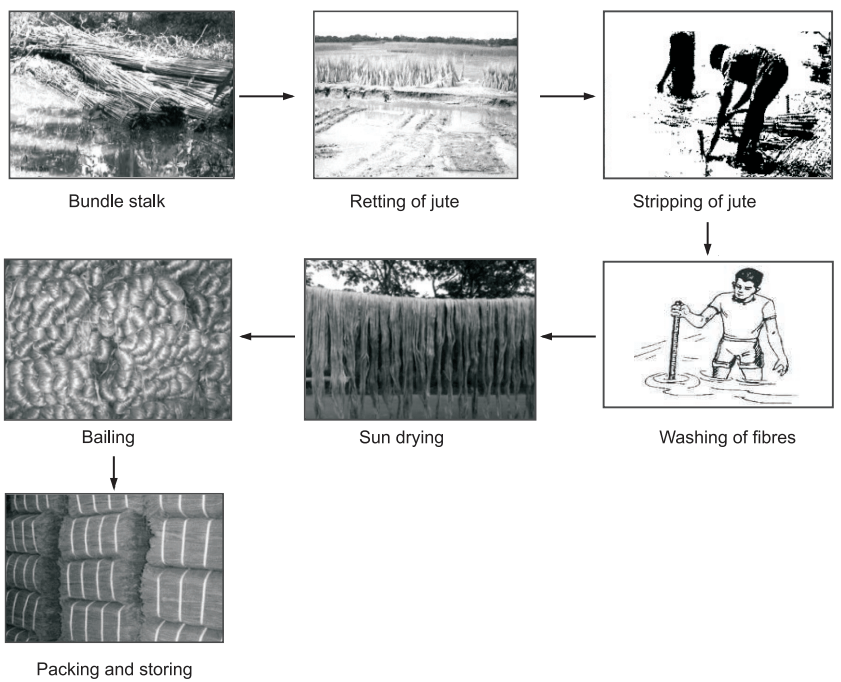

Production of Fibre: The unbranched stems of the jute plant are cut and formed into a bundle. This should carry out before the flowering stage. The jute fibre comes from the stem and ribbon (outer skin) of the jute plant. The fibres are first extracted by the retting method either in the pond or in any waterlogged condition. Retting is a microbial process by which the jute plant is immersed in water and the fibre is loosened from the woody core of the jute plant. This process softens the tissues and breaks the hard pectin bond between the bast and jute hurd (inner woody fibre stick) and the process permits the fibres to be separated. It has been found that jute stems ret most rapidly at 340C. At this temperature, it takes generally 8-12 days for complete retting. The retting process consists of bundling jute stems together and immersing them in slow running water. After the retting process, stripping begins. In the stripping process, non-fibrous matter is scraped off, leaving the fibres to be pulled out from within the stem and washed in clear, running water. Then they are hung up or spread on thatched roofs to dry. After 2-3 days of drying, the fibres are tied into bundles. The jute fibres are graded according to the colour, length and smoothness of the fibres (Fig. 1.6).

Chemical Constituents: Jute fibres contain mainly cellulose (60%) and hemicellulose (24%). Apart from that Lignin, fats and wax are also present.

Uses of Jute:

Jute is the second most important vegetable fibre after cotton. Jute is used chiefly to make cloth for wrapping bales of raw cotton and to make sacks and coarse cloth. The fibres are also woven into curtains, chairs, coverings and carpets. The fibres are used alone or blended with other types of fibres to make twine and rope.

Substitutes: Fibres of Hibiscus cannabinus are used as substitutes for jute fibres.

Hemp

Biological Source: The pericyclic fibre is obtained from the plant of Cannabis sativa.

Family: Cannabinaceae.

Distribution: The hemp is originated from central Asia, mainly from China. It is cultivated in India, Romania, Hungary, Poland and Turkey. In India, MP, Himachal Pradesh and Jharkhand are cultivating hemp for industrial use.

Description of Plant: The plant grows up to 5 m in height. The slender stalks are hollow except at the tip and base. The leaves are compound with a palmate shape. The flowers are small and greenish-yellow (Fig. 1.7).

Preparation of Fibres: Fibres are obtained by subjecting the stalks to retting, drying and crushing. Finally, a shaking process completes separation from the woody portion and releases the long, fairly straight fibre, or line. Recently new technologies such as ultrasound and steam explosion have been developed for the separation of the fibres from the stalk. There are two principal types of fibres in hemp viz. bast or long fibres and hurds or inner short fibre. Bast fibres are of two types namely, primary bast fibres and secondary bast fibres. The primary bast fibres are made up of approximately 70% of the fibres and are long. They contain high cellulose and low lignin. Primary bast fibres are the most valuable part of the stalk and are generally considered to be among the strongest plant fibres known. Secondary bast fibres are made up of the remaining 30% of the bast fibres and are medium in length and higher in lignin.

Chemical Constituents: Hemp fibres mainly contain 77% cellulose and 10% hemicellulose. Apart from that lignin, fat, wax and pectin are also present.

Uses of Hemp

Natural fibres from the hemp stalk are extremely durable and can be used in the production of textiles, clothing, canvas, rope, cordage, archival grade paper, paper, and construction materials. Long hemp fibres are used in clothing, home furnishing textiles and floor coverings, whereas short fibres are used in making insulation products, fibreboard and erosion control mats.

Make sure you also check our other amazing Article on : Types of Plant Tissue Cultures