Table of Contents

Definition of Pharmaceutical Suspensions

Pharmaceutical suspensions can be defined as biphasic liquid dosage forms in which one or more solid active medicaments are dispersed/suspended with or without the help of suspending agents, with suitable additives in a liquid medium (vehicle), meant for internal, external, and parenteral administration.

Ideal properties of suspensions

- It should be physically, chemically and microbiologically stable.

- The dispersed phase should have a size range of 5 to 50µm.

- Suspensions should have desired viscosity so that they can be easily poured from the container.

- The sediment produced in the suspensions should be easily redispersed after shaking.

- Suspensions should have a pleasing odour, colour and palatability.

- Suspensions should be free from large or gritty particles.

- Suspensions meant for parenteral administration should have good syringibility.

- Parenteral /ophthalmic suspensions should be sterilizable.

Advantages of the Pharmaceutical Suspensions

- Easy to prepare and administer and easy to swallow the preparations for all categories of patients.

- Insoluble active medicaments can be conveniently dispensed ex: Antacid suspensions.

- Suspension can improve the chemical stability of certain drugs ex: Procaine penicillin G.

- Drugs in suspension exhibit higher bioavailability than solid dosage forms.

- Rapid onset of action can be controlled ex: Protamine Zinc-Insulin suspension.

- Suspension can mask the unpleasant/ bitter taste of certain drugs ex: Chloramphenicol.

- Drug release can be controlled by preparing sustained release suspensions.

Disadvantages of Pharmaceutical Suspensions

- Physical stability, sedimentation and compaction can cause problems.

- Bulky in preparation, care must be taken during handling and transport.

- Uniform and accurate doses can not be achieved unless suspensions are packed in the unit dosage form.

Classification of the suspensions

Based on the route of administration.

- oral suspensions ex: Ampicillin suspensions.

- Externally applied suspensions ex: Calamine suspensions (lotions).

- Parenteral suspensions ex: Crystalline zinc insulin suspensions.

Based on the nature of the dispersed phase.

- Diffusible suspensions ex: magnesium trisilicate suspensions; kaolin suspensions.

- Indiffusible suspensions ex: Sulphadimidine suspensions; Zinc oxide suspensions.

- Suspensions containing precipitate forming liquids ex: lobelia and stramonium suspensions.

- Suspensions containing potent medicaments ex: Hyoscine hydrobromide suspensions.

- Suspensions containing oily substances ex: Eucalyptus oil suspensions.

- Suspensions containing poorly wettable solids ex: Precipitated sulphur suspensions.

Based on the appearance of the dispersed phase.

- Flocculated suspensions ex: Bismuth subnitrate suspensions with flocculating agents.

- Deflocculated suspensions ex: Bismuth subnitrate suspensions.

Prepared by chemical reaction ex: Magnesium hydroxide suspensions.

Suspensions containing diffusible solids:

Diffusible solids are light, easily wettable water-insoluble solids and are readily mixed with water after shaking and distributed evenly for a certain period, which is sufficient to administer the desired dose ex: calcium carbonate, light kaolin, light magnesium carbonate, magnesium trisilicate, bismuth carbonate rhubarb powder.

Method of preparation of suspensions

- Mix one or more diffusible solids in a mortar in ascending order concerning their quantity and triturate to get a fine powder.

- Add ¼ volume of the vehicle to produce smooth cream.

- Add any other additives prescribed in the formula slowly with trituration.

- Dilute the smooth cream with the remaining quantity of vehicles to get the desired volume.

Formula

Bismuth carbonate 1g

Sodium bicarbonate 0.7g

Tincture of belladonna 0.4ml

Water to 30ml

Suspensions containing Indiffusible

Indiffusible solids are water-insoluble powders and are readily mixed with water after shaking and not distributed evenly for a certain period due to rapid settling, which makes it inconvenient for the administration of the desired dose.

Examples: Aspirin, chalk powder, aromatic chalk powder, phenobarbitone, succinyl sulphathiazole, sulphadimidine, calamine, hydrocortisone, precipitated sulfur, zinc oxide, triamcinolone acetonide

Rectification: The simplest way of correcting this problem is to increase the viscosity of the vehicle by adding suitable thickening agents which delays the rate of sedimentation ex: Acacia, tragacanth, Sodium alginate, starch mucilage, methylcellulose, compound tragacanth powder (CTP- Mixture of acacia, starch, tragacanth, and sucrose), tragacanth mucilage (mucilage of tragacanth in alcohol and chloroform water).

Method of preparation: Method 1 (using CTP)

- Mix one or more indiffusible solids in a mortar in ascending order concerning their quantity and triturate to get fine powder to add 2gm/100ml CTP and mix well.

- Add ¼ volume of the vehicle to produce smooth cream.

- Add any other additives prescribed in the formula slowly with trituration.

- Dilute the smooth cream with the remaining quantity of vehicles to get the desired volume.

Method 2 (using tragacanth mucilage)

- Mix one or more indiffusible solids in a mortar in ascending order concerning their quantity and triturate to get a fine powder.

- Add ¼ volume of the tragacanth mucilage to produce smooth cream.

- Add any other additives prescribed in the formula slowly with trituration.

- Dilute the smooth cream with the remaining quantity of vehicles to get the desired volume.

Note: Whenever suspensions containing diffusible or indiffusible solid is present and there is the presence of foreign particles, these must be removed by passing the suspensions through a muslin cloth.

Formula

Aromatic chalk powder 2g

Opium Tincture 2ml

Ammonia solution 0.5ml

Tragacanth in powder (0.2%) 0.2g

Chloroform water double strength 25ml

Purified water to 100ml

Flocculated suspensions

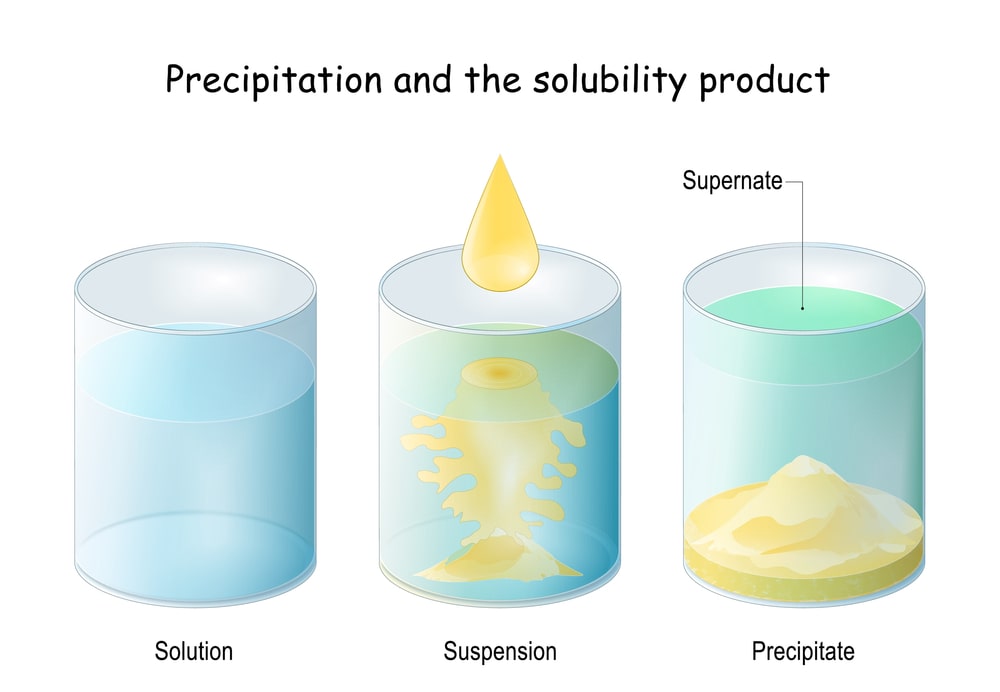

- Suspensions containing dispersed particles in the form of floccules i.e aggregation of dispersed particles to for network structure called floccules.

- Flocculation is the result of lowering of electrical forces of repulsion in a dispersed system, resulting in predomination of the force of attraction, under this condition the dispersed particles approach each other more closely and form aggregates known as flocs.

- Flocculated suspensions are prepared by using flocculating agents ex: electrolytes like KH2PO4, aluminium chloride, surfactants like polysorbate 80, 60 and polymers like xanthan gum, gelatin and methylcellulose.

Deflocculated suspensions

- Suspensions containing dispersed particles in the form of a single entity i.e. single-particle distribution.

- A deflocculated suspension is one in which the electrical repulsive forces between particles exceeds the attractive forces, the particles are kept apart as individuals deflocculated suspensions are prepared by using suitable deflocculating agents ex: Acacia, tragacanth, bentonite etc.

Make sure you also check our other amazing Article on : Elixir