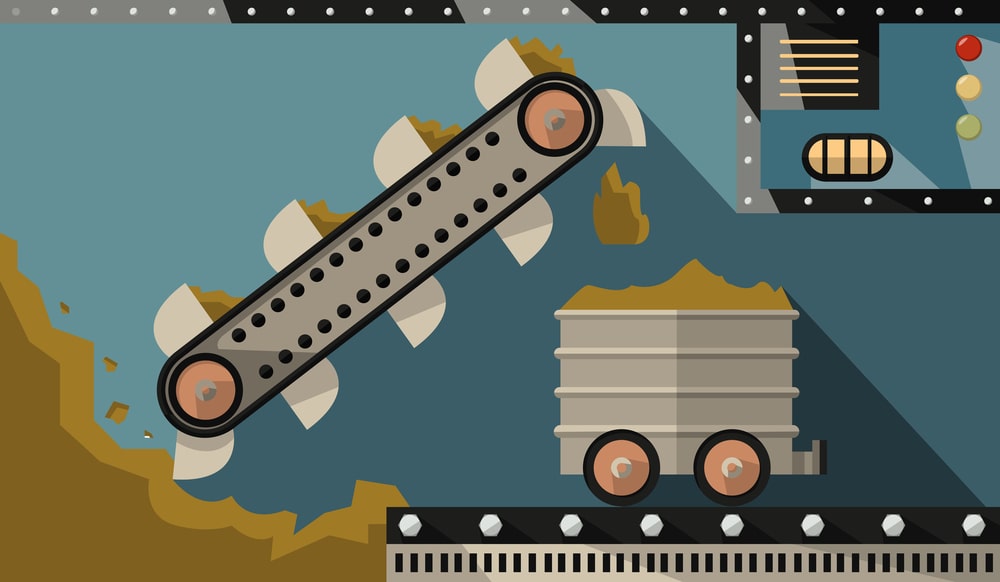

Principle Bucket Conveyors

The principle of bucket conveyors is horizontal, inclined, or vertically placed motor-driven chains carrying buckets convey the solid material from the feed point (boot) to the discharge point.

Construction

Buckets are used for loading the materials. The buckets are made of cast iron or stamped steel and are available in many forms. Flat buckets are used for materials that are sticky. Heavily stamped steel buckets are employed for large lumps, for example, coal and crushed stone.

The buckets are attached to belts or chains. The chains are endless and buckets are riveted between two chains (Figure 1.1). The chains are generally long pitch, straight and side type. The buckets are spaced to prevent interference in loading and unloading. For heavier loads, two chains may be used. The attachments are slightly above the level of the chain so that the ends of the sprocketed booth do not strike the back of the buckets.

The weight of the materials in the conveyor results in the stretching of the chain. Therefore, tightening devices are generally provided for altering the position of the sprocket at the foot of the elevator.

- In horizontal runs, buckets overlap each other and the feed is introduced as a continuous stream of material.

- In vertical lines, the buckets are pivoted in such a way that they hang freely between the chains. Therefore, the conveyor acts as an elevator.

At the foot of the elevator, a structure known as a ‘boot’ is used for feeding the buckets and also for tightening the chains. Buckets are sometimes completely enclosed in a casing. The casing is made of wood or steel sheet.

Working

The elevators are generally driven from the head sprocket. At the foot of an elevator, ‘boot’ helps in feeding. The buckets are normally fed by digging into the materials, particularly in the case of loose material and granular solids. The buckets maintain their carrying capacity by gravity, but they can convey the material horizontally or vertically, or in any desired path. Loading can be done by the flow of material through a chute into the buckets. Buckets may be readily discharged at any point by a tripping device, causing each bucket to turn 90 degrees. The types of discharges are continuous, positive, and centrifugal.

Applications: Bucket conveyors are used in transporting coal, crushed stone, grains, etc.

Advantage: Bucket conveyors are very flexible.

Make sure you also check our other amazing Article on : Diaphragm Pump