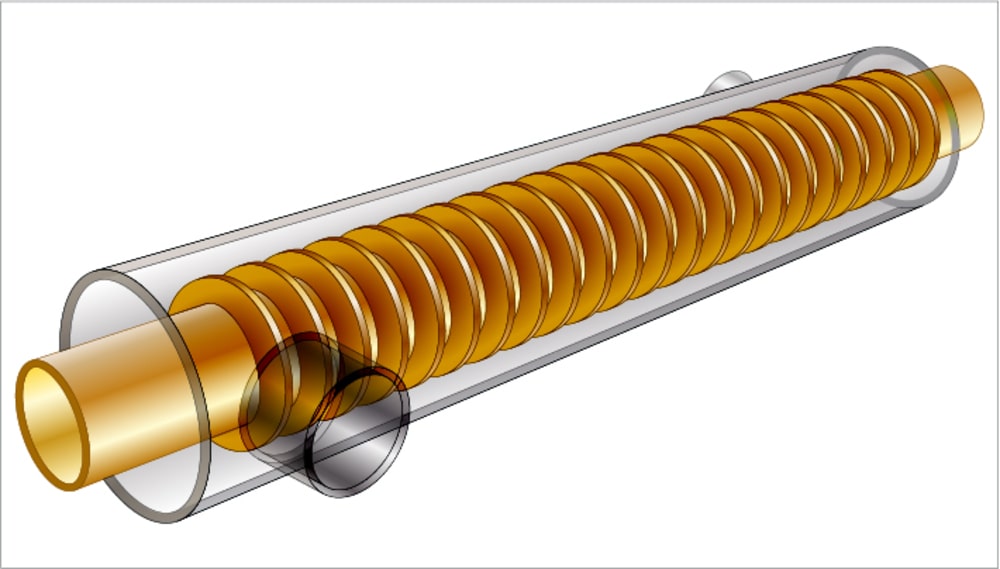

Tubular Heat Exchanger: Shell-and-tube heater is the simplest form of a tubular heater. It is a single-pass tubular heater.

Construction of Tubular Heat Exchanger

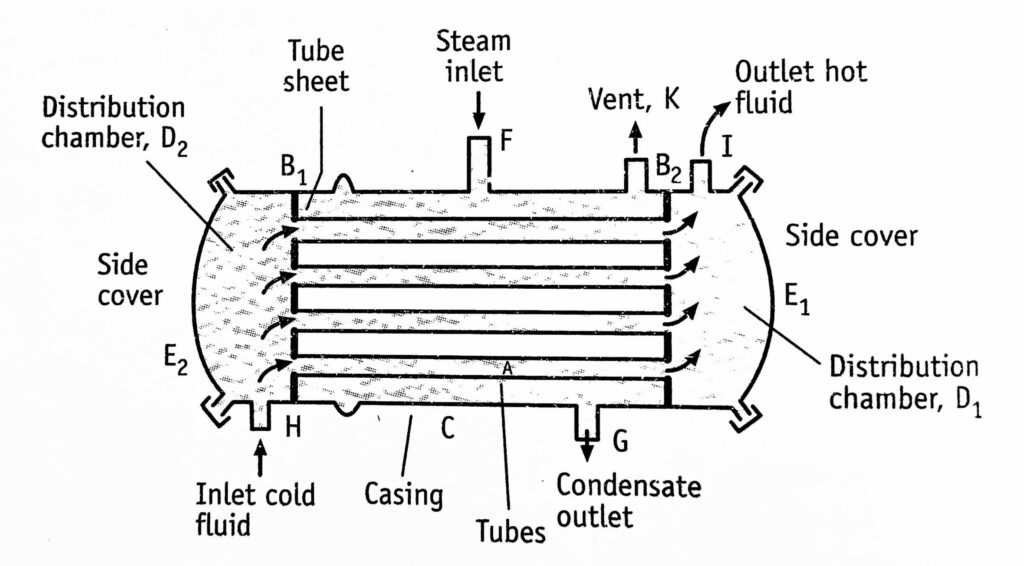

The construction of a simple tubular heater is shown in Figure 1.1. A tubular heater consists of a bundle of parallel tubes. which are relatively thin-walled. The ends of these tubes are expanded into two tube sheets. B1 and B2. The bundle of tubes is enclosed in a cylindrical shell or casing, C. to which the tube sheets are fitted. Many heaters have a cast iron shell.

Two distribution chambers, D1 and D2 are provided at each end of the casing C. Fluid inlet is provided to the distribution chamber Dy The heated fluid outlet is provided to the distribution chamber D. Two covers, E1 and E2 are provided to close the distribution chambers from the sides. Steam or other vapour is introduced by a connection, F. Provisions are made for the escape of non-condensable vapour K and condensed vapour to drain at G.

Working

Steam or any vapour is introduced through a steam inlet F into the space surrounding the tubes. The stream flows down the tubes. In this process, the tubes get heated rapidly due to the high values of steam film coefficients. The condensed vapour drains through a condensate outlet at G. Non-condensable gases, if any, escape through the vent K provided at the top of the casing.

The fluid to be heated is pumped through the cold fluid inlet H into distributing chamber D2. The fluid flows up through the tubes. The steam and fluid are physically separated but are in thermal contact through the thin tube walls. The fluid in the tubes gets heated due to heat transfer by conduction through the metal wall, followed by a stagnant layer and finally by convection. The total heat transfer is affected by a single pass of fluid. Thus, the heated fluid reaches the distributing chamber D and leaves through the hot fluid outlet, I.

In the sheet-and-tube heater, the cross-sectional area of the tubes is larger. Hence, the velocity of the fluid inside the tubes is low.

Advantage: In a single-pass tubular heater, a large heating surface can be packed into a small volume.

Disadvantages:

- The velocity of fluid flowing in these tubes is low, because of the large cross-sectional area or larger surface.

- The expansion of the tubes and shell takes place due to differences in temperatures. This may lead to the loosening of the tube sheets or buckling the tubes.

Make sure you also check our other amazing Article on : Bucket Conveyors