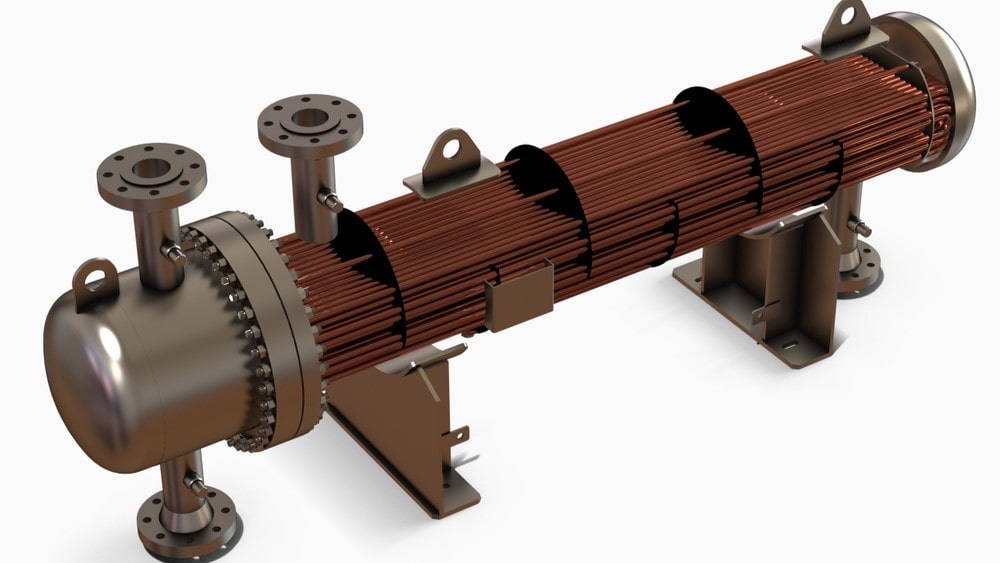

Multipass Heat Exchanger: In a multi-pass heater, the velocity of fluid can be increased. As a result, the heat transfer coefficient also increases. As the name indicates, the liquid to be heated is passed through the tubes several times before leaving the equipment. This facilitates effective heat transfer. Therefore, multi-pass tubular heaters are superior to single-pass shell-and-tube heaters.

Construction of Multipass Heat Exchanger

The construction of a multi-pass heater is the same as the tubular heater mentioned above, however, with some modifications (Figure 1.1).

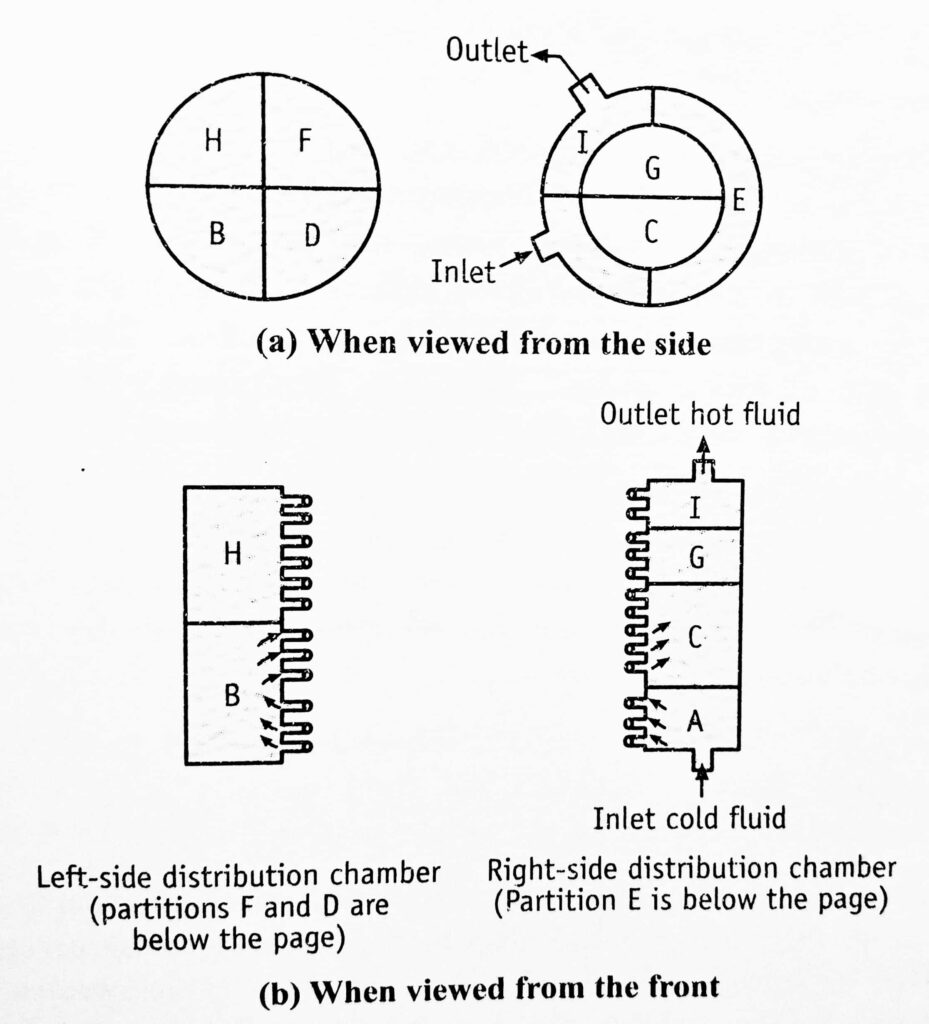

A tubular multi-pass heater consists of a bundle of parallel tubes. The ends of these tubes are expanded into two tube sheets. The tube bundle is wrapped in a cylindrical casing. Two distribution chambers are provided at each end of the casing. Since the heater is multi-pass, the same liquid has to flow through several tubes back and forth. In order to facilitate this process, distribution chambers are partitioned by means of baffles and their arrangements are different in the two chambers (Figure 1.1). The entrance and exit points of the fluid are arranged in the same distribution chamber (right side).

Working

Steam is introduced through the connection into the space surrounding the tubes. As the steam flows down, the tubes get heated. The condensed vapor is drained. Non-condensable gases, if any, escape through the vent provided at the top of the casing.

The fluid to be heated is pumped at high velocities into the right distribution chamber through compartment, A. High velocity facilitates effective heat transfer. In this construction, fluid is directed to enter only a fraction of the tubes by means of baffles placed in the distribution chamber. same The liquid enters compartment A and flows to the left into complement B. back to the right to compartment, and so on in the sequence of alphabetical order. During this process, fluid in the tubes gets heated, due to heat transfer by conduction through the metal wall, followed by a stagnant layer, and finally by convection. The net result is the enhanced rate of heat transfer. Thus, the fluid passes back and forth through several tubes and then leaves the equipment at I.

If the fluid is to be introduced at high velocities, pumping should be effective, which increases the cost of the power, though the cost of the heater is low. Too low a velocity saves power for pumping but needs a very large heater. Therefore, a balanced approach should be worked out based on the economy.

Advantages

Multi-pass construction decreases the cross-section of the fluid path, thereby increasing the fluid velocity. Thus, multi-pass tubular heaters are superior to single-pass shell-and-tube heaters.

Disadvantages:

- The fabrication of a multi-pass heater is more complicated.

- The pressure drop through the apparatus is increased, because of the enhanced velocity of fluid flow.

- More exit and entrance points increase the friction losses. This increases the cost of pumping fluid.

Make sure you also check our other amazing Article on : Bucket Conveyors