In floating-head two-pass heater. the ends of the tubes are structurally independent of the shell.

Construction

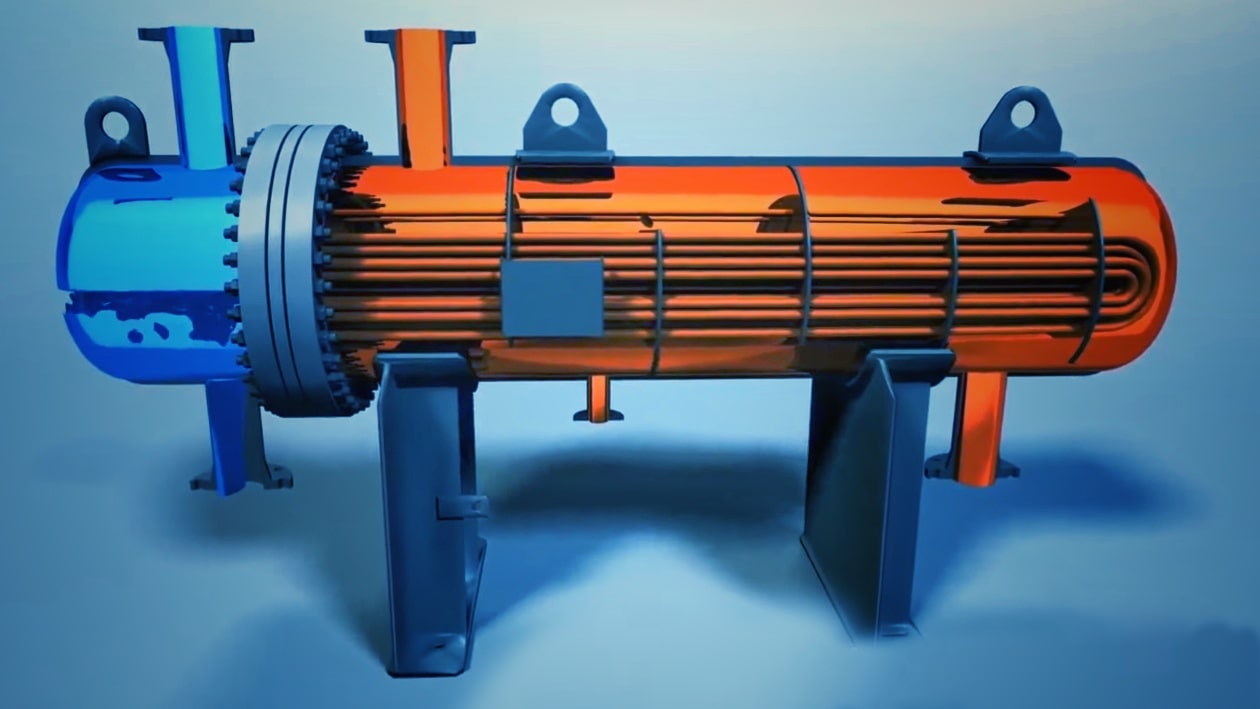

The construction of a two-pass floating head heater is shown in Figure 1.1. Its construction is the same as a tubular heater with some modifications.

The two-pass floating head heater consists of a bundle of parallel tubes Which are enclosed in a shell (casing). The right side of the distribution chamber is partitioned and the fluid inlet and outlet are connected to the same chamber. The partition is such that both have an equal number of tubes. On the left side, the distribution chamber is not connected to the casing. It is structurally independent, which is known as a floating head The other end of the tube is embedded into the floating head. Steam or other vapour is introduced through the inlet to the shell. Provisions are made for the escape of non-condensed vapour and an exit for the condensate.

Working on Floating Head Two Pass Heater

Steam is introduced through the inlet (Figure 1.1). As the steam flows down the tubes, they get heated. The condensed vapour escape through the bottom of the shell. Non-condensable gases, if any. escape through the vent at the top of the shell.

The fluid to be heated is introduced into the distribution chamber on the right side of the heater. The fluid flows through a few tubes present in that part of the partition. The fluid reaches the floating head and changes direction. Now it passes back to the next part of the partitioned chamber on the right side. Therefore, the fluid flows twice through the tubes, i.e., two passes. During this process, fluid in the tubes gets heated, due to heat transfer by conduction through the metal wall, followed by a stagnant layer and finally by convection. Then the fluid leaves the outlet provided in the shell.

Advantages

In a shell-and-tube heat exchanger, tubes and shells may get expanded due to differences in temperature. Similarly, contractions are also possible when the heater is switched off. It leads to the loosening of tube sheets or buckles the tubes. Therefore, constructing the tubes independent of the shell can prevent these effects. Such an arrangement is a floating head.

Make sure you also check our other amazing Article on : Tubular Heat Exchanger