Laminar airflow is an enclosed bench cabinet. It is designed to prevent contamination of biological samples or any particle-sensitive materials.

Table of Contents

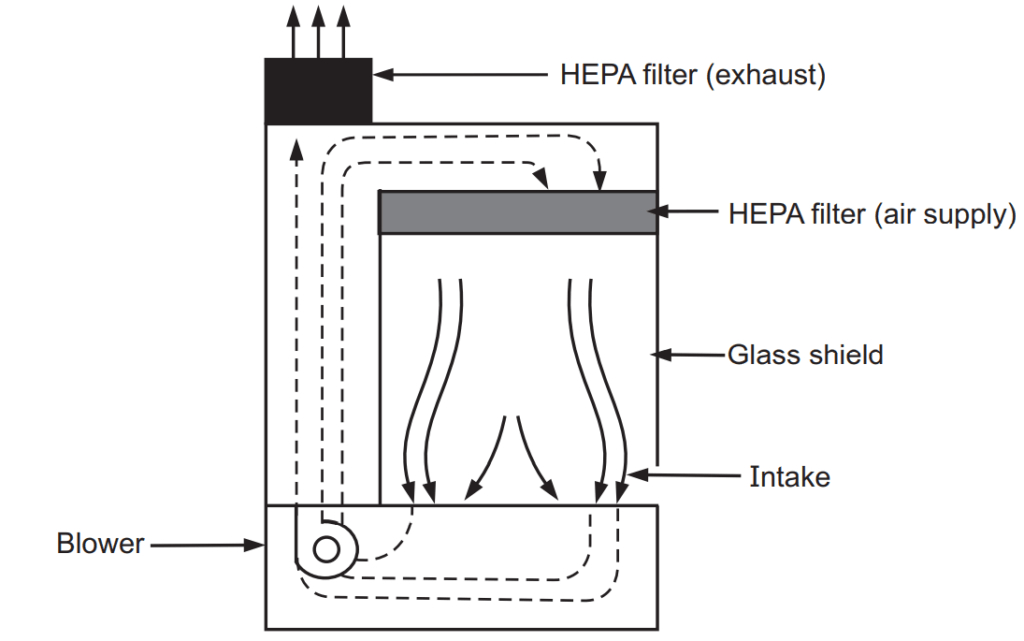

Principle of Laminar flow

The air is passed through a HEPA filter which removes all airborne contamination to maintain sterile conditions.

Construction of the Laminar flow

It is low cost and does not require more space. The cabinet is made up of stainless steel without gaps or joints thereby preventing the buildup of bacteria from collecting anywhere in the working zone. They are also known as clean benches because the air for the working environment is thoroughly cleaned by the precision filtration process. They consist of a filter pad, a fan, a light with 100 lux and UV tube to disinfect the bacterial growth, and a HEPA filter. The fan sucks the air through the filter pad to trap the dust particles. After that, the pre-filtered air has to pass the HEPA filter where all the microorganisms are removed 99.97% of airborne particles 0.3 µm in diameter. Finally, sterile air flows into the working area without risk of contamination. The air flows at a speed of 100 ft/min and sweeps dust particles making the entire room free of particulate matter. This helps to perform work under aseptic conditions.

Air Flow Pattern

Generally, airflow patterns in the clean rooms are of three types viz. unidirectional airflow, non-unidirectional airflow, and combined airflow.

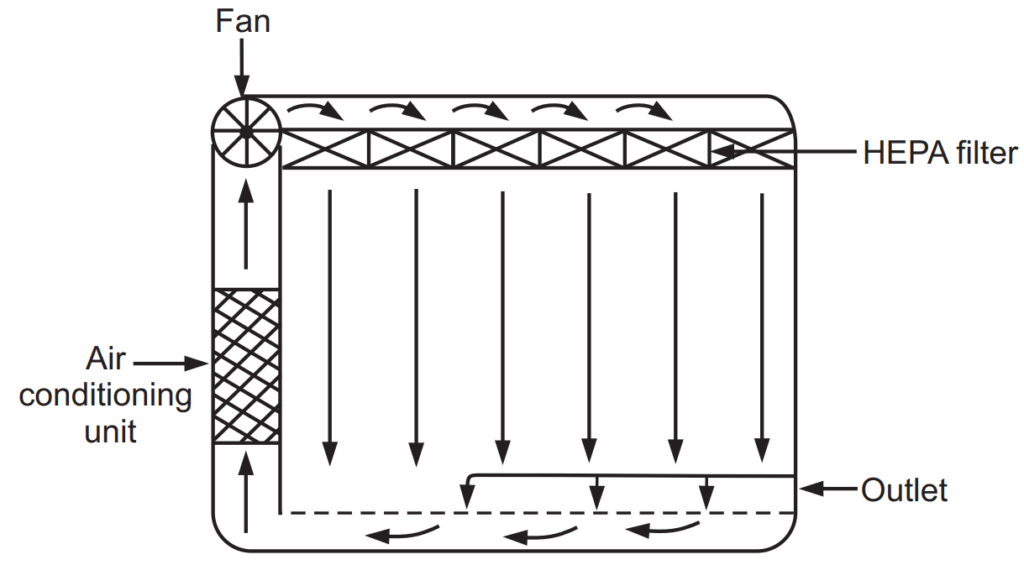

Unidirectional airflow is an airflow pattern in which essentially the whole body of the air within a confined area moves with uniform velocity and in a single direction with parallel air streams which means it is an airflow where a fluid flows in one direction with no interruptions from turbulence. It should have uniformed airflow at a speed of ± 15% and the speed of the air is measured as it exits the HEPA / ULPA filter (Fig. 1.1)

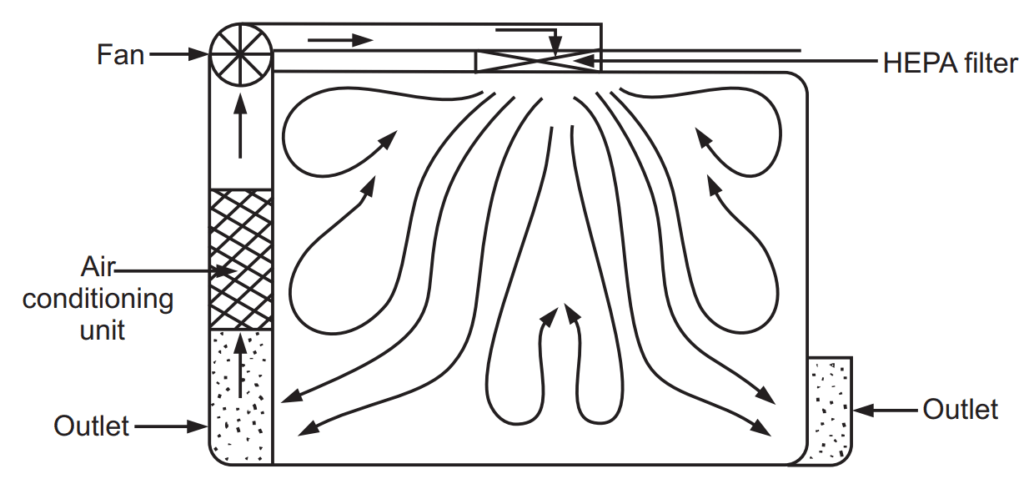

Non-unidirectional air flow is an air distribution where the supply air entering the clean zone mixes with the internal air by means of induction. The room air change rate per hour is calculated by the total airflow for the room is divided by the room volume and a capture hood is used to measure the volume of air exiting the HEPA / ULPA filter (Fig. 1.2).

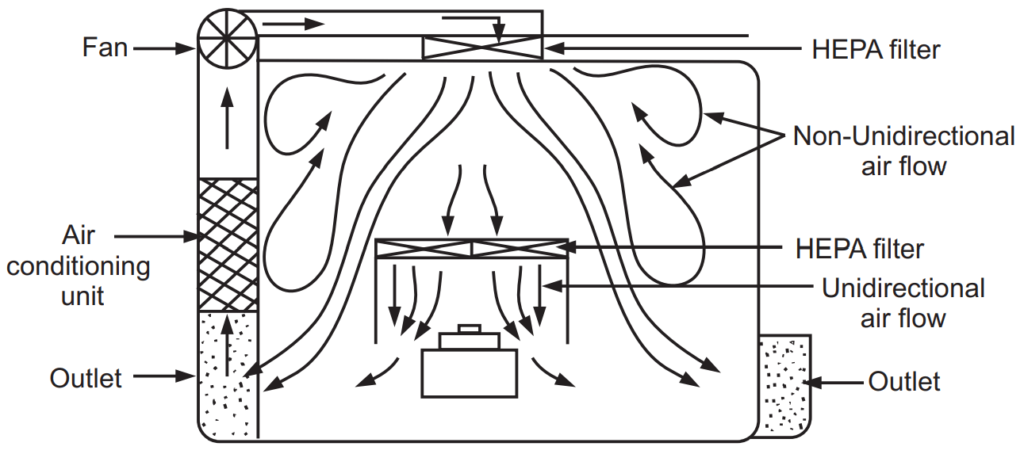

Combined air flow is a combination of both Unidirectional and Non-Unidirectional air flows (Fig. 4.6).

Advantages of Laminar flow Equipment

- The persons working in the area do not feel the movement of the air.

- The body of the filters is made up of stainless steel which is not favorable for bacterial growth.

- The HEPA filter can reduce the contamination.

Types

Mainly two types likely the Vertical laminar air flow bench and the Horizontal laminar air flow bench.

Horizontal Laminar Flow Cabinets:

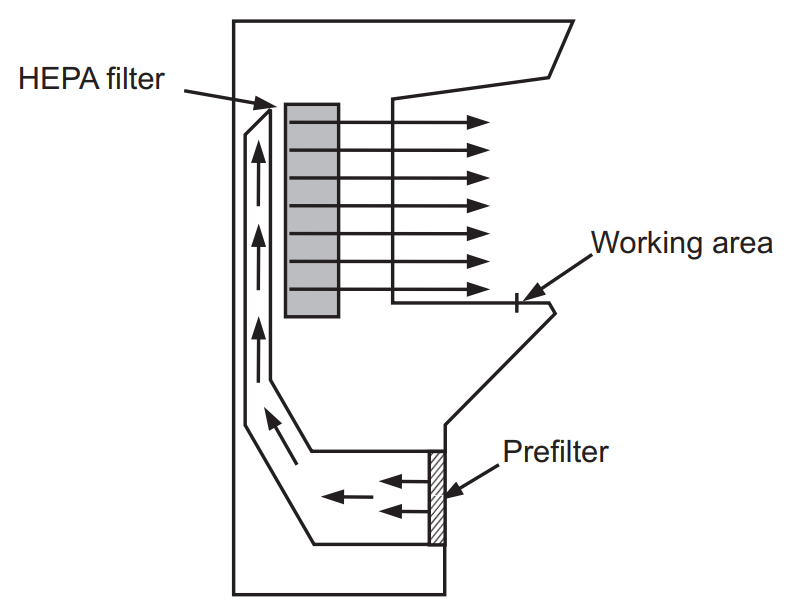

In this cabinet, the direction of air flow comes from above but then changes direction and is processed across the work in a horizontal direction. The constant flow of filtered air provides material and product protection (Fig. 1.4).

Vertical Laminar Flow Cabinets:

It is also the same as well as horizontal Laminar Flow Cabinets with the laminar air directed vertically downwards onto the working area. The air can leave the working area via holes in the base. Vertical flow cabinets provide greater operator protection (Fig. 4.8).

Biological safety cabinets come in several classes. For all classes, the air is HEPA filtered before being released as exhaust.

Class-I Laminar Flow Hoods: They are very simple laminar flow-hood styles. They provide adequate protection to both the user and the materials being worked with, but they do not protect the work substance from contamination. They are similar to chemical fume hoods, which contain hazardous fumes but do not disinfect.

Class-II Laminar Flow Hoods: They provide an aseptic environment in addition to protection from fumes and gases. They protect competently from the dangers of hazardous materials. They are safe and ideal for that application.

Class-III Laminar Flow Hoods: They provide the ultimate level of possible protection. They are gas-tight and so protect the worker from the danger of exposure to human pathogens. They are used for many applications involving potentially infectious substances.

Make sure you also check our other amazing Article on : Phenol Coefficient Test