Mechanical Method Of Sterilization to the solution to be sterilized is pass through depth filter or screen filter which includes

- Particulate filter

- Microbial filter

- Final filter

Table of Contents

Filtration

Filtration allows for the exclusion of organisms based upon size. There are many types of filtration techniques, but when sterilizing a system membrane filtration is used. To obtain a sterile filtrate it is necessary that the filter and all connecting parts likely to come into contact with the filtrate must be sterile. Contaminants are traps on the membrane filter due to their larger size than the pore size of the membrane. It is useful for antibiotic solutions, sera, carbohydrate solutions, etc. This method does not destroy but removes the microorganisms. It is used for both the clarifications and sterilization of liquids and gases as it is capable of preventing the passage of both viable and non-viable particles.

The major mechanisms of filtration are sieving, adsorption, and trapping within the matrix of the filter material. Based on the pores size of the membrane filter, various types of microbes are trapped. Like, 0.01 µM is used to trap the smallest viruses, 0.025 µM is used to trap larger viruses, 0.45 µM is used to trap the largest bacteria, 1.2 µM is used to trap protozoa and smallest unicellular algae, etc.

Some observations are essential for successful sterilization by filtration:

- The whole apparatus must be sterile.

- An aseptic technique should be followed to minimize the risk of contamination.

- The assembly of the filtration unit should be so adjusted that there is minimal exposure of filtrate to the atmosphere.

- The filter selected must be fine enough to obstruct the passage of all bacteria.

Four steps for sterilization by filtration

- Filtration of the solution through one of the bacteria-proof filters.

- Aseptic distribution of the filtered solution into the previously sterilized final containers.

- Aseptic closure of the containers.

- Performing the sterility test.

There are various types of filtrations used for various purposes viz. HEPA filter, sintered glass filters, colloidal or membranous filtrates, earthenware candles, etc. The various types of bacteria-proof filters used are as follows.

Ceramic filters: These are also known as filter candles, made of porcelain or kieselguhr and are available in a range of pore sizes. Kieselguhr filters are usually softer than the porcelain type. The candle is placed in the solution to be sterilized and its opening is attached to the vacuum system. When the vacuum has applied the pressure inside the candle is decreases. Due to the difference in pressure between the outside and inside of the candle, the solution moves into the candle. The filtrate is collected in a sterile container. The main disadvantage of ceramic filters is their tendency to absorb materials from aqueous solutions.

Seitz filter: It consists of two parts. The lower part holds a perforated disc and the upper part is a compressed asbestos sheet. Two parts are joined together with the help of nuts. There is a valve on the upper part through which a vacuum is applied. Due to the fibrous nature of asbestos pads, it may shed fibers into the filtrate and also absorb drugs from the solution. Hence, a few ml of filtrate should always be rejected and sintered glass disc may also be fixed in the filtration unit immediately after the Seitz filter.

Sintered glass filters: They are made from borosilicate glass. The glass is finely powdered and particles of the required sizes are separated and are then packed into disc moulds. These discs are fused to funnels of suitable shape and size. Sintered glass filters are available in different pore sizes and are numbered accordingly. For bacteria, proof filtration number 5 or 3 is used. The filtration is carried out under reduced pressure. Sintered glass filters do not absorb the medicaments from the solution. These filters are made from borosilicate glass, so the change of pH of the solution does not occur.

Sintered metal filters: They are the metallic counterpart of sintered glass filters. These are usually made from stainless steel. They have the advantage of having greater mechanical strength.

Membrane filters: These are made of cellulose acetate or cellulose nitrate. These are fixed in metallic holders similar to those used with asbestos pads. The pore size in the membranes lies in the range of 100-150 µ. They are also called millipores filters. They are suitable for sterilizing aqueous and oily solutions but are not suitable for organic solvents like alcohol, ketones, esters, or chloroform.

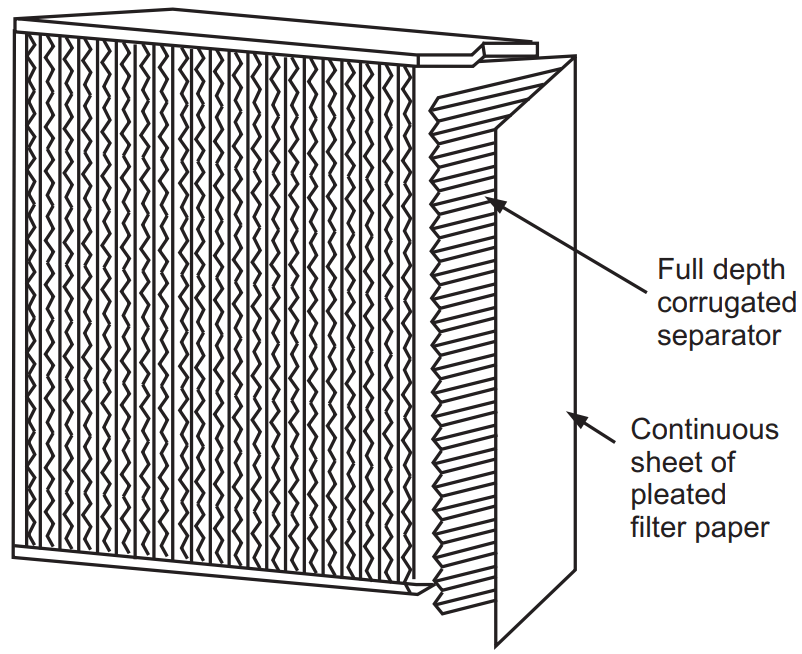

Air filter: (HEPA filter): It is high-efficiency particulate air or originally called High-Efficiency Particulate Absorber (HEPA). It is used to describe filters that can trap 99.97 per cent of particles that are 0.3 microns (Fig. 2.5). Air particles are circulated through the HEPA filter in four directions viz.

- Direct Impaction: Large contaminants, such as certain types of dust, mould, and pollen, travel in a straight path, collide with fibre, and stick to it.

- Sieving: The air stream carries a particle between two fibres, but the particle is larger than the gap, so it becomes ensured.

- Interception: Airflow is nimble enough to reroute around fibres, but, thanks to inertia, particles continue on their path and stick to the sides of fibres.

- Diffusion: Small, ultrafine particles move more erratically than larger ones, so they are more likely to hit and stick to fibres (Fig. 1.1).

Advantages

- The method is suitable for the sterilization of thermolabile medicaments, such as blood products, insulin and enzymes.

- All types of bacteria i.e., living as well as dead, are removed from the preparation.

- Both clarification and sterilization are done side by side.

- It is an excellent method for the rapid supply of a small volume of a parenteral solution in an emergency.

Disadvantages

- The method is not a reliable one and therefore a sterility test is necessary.

- The suspension and oily preparations cannot be sterilized by this method.

- There are chances of absorption of medicaments from a solution by the filter.

- Defects in the media are not immediately detectable.

- An aseptic technique is necessary.

- Highly trained staff is required.

- The process is only suitable for medicaments that are in solution form.

Applications of sterilization by filtration

This filtration method is useful for sterilization of parenteral solutions containing thermolabile medicaments without any decomposition e.g. insulin, blood serum, and other products containing protein matters, heat-sensitive injections, biological products, etc.

Make sure you also check our other amazing Article on : Physical Methods of Sterilization