Principle

Scraped Surface Heat Exchanger: In this type of liquid-liquid heat exchanger, a spring-loaded scraper blade is included for enhancing the overall heat transfer coefficients. The scraper blade rotates at a certain speed and scraps the inside liquid surface layer of the inner tube, which is otherwise stagnant. This permits the replacement of existing liquid layers with a new portion of liquid. Thus the exchange of heat is effective.

Construction of Scraped Surface Heat Exchanger

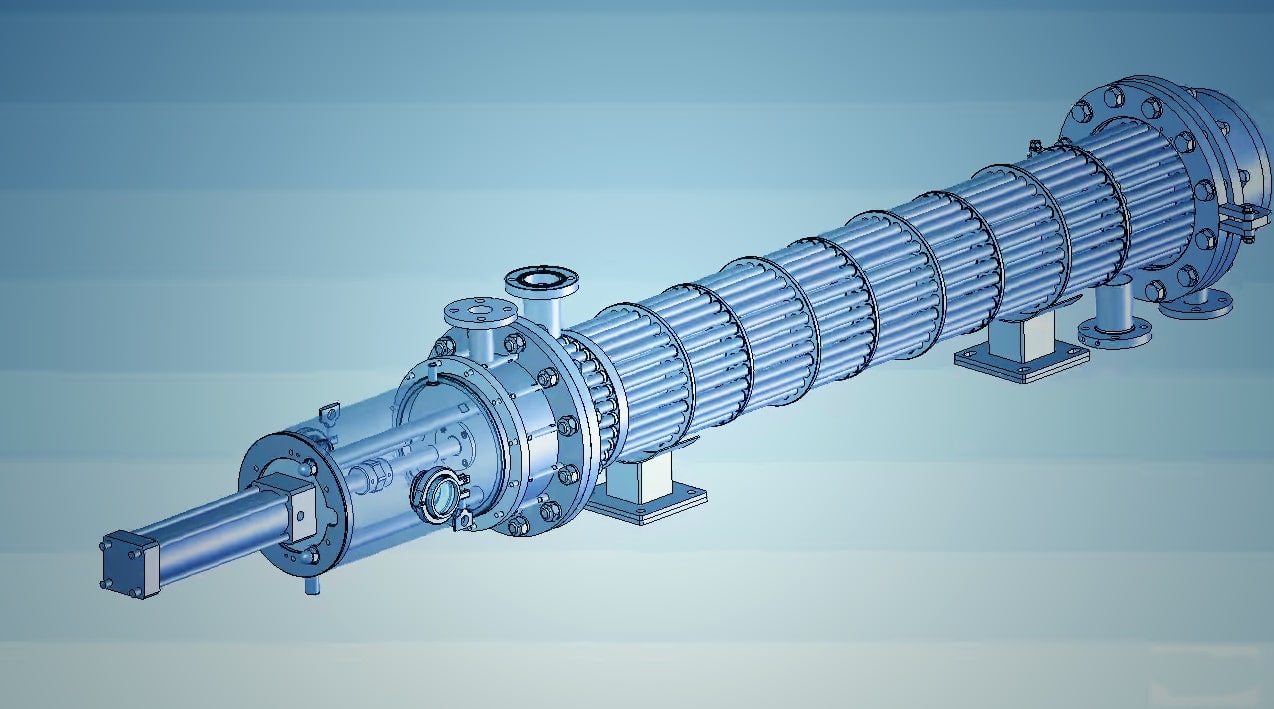

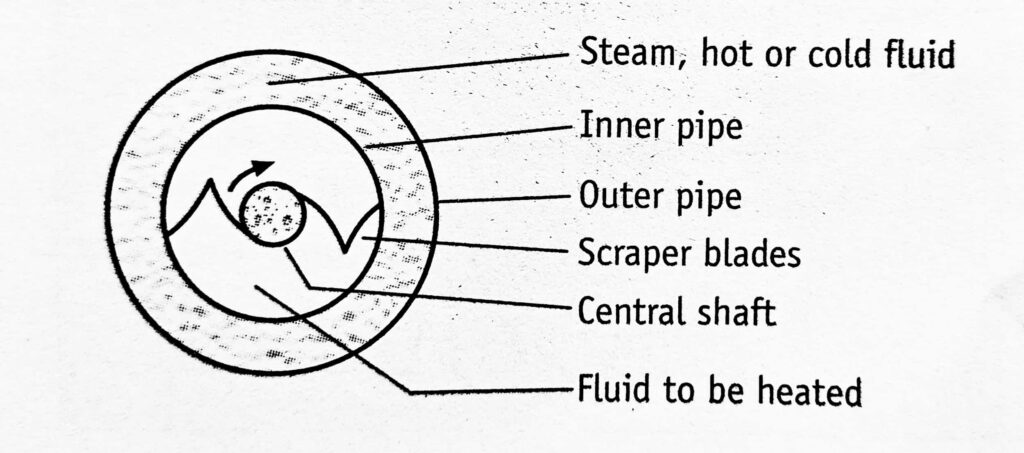

The construction of a scraped-surface heat exchanger is given in Figure 1.1. It consists of a double pipe construction: one is kept inside the other. The common sizes are 6 inches inside the pipe and 8 inches outside the pipe. In the inner tube, two or more spring-loaded scraper blades are attached longitudinally to a central shaft. The shaft is connected to a motor for allowing the blade to rotate. The other end of the blade reaches closer to the inner pipe wall. These double pipe units are commonly connected in series and arranged in double stands. Often, the system can employ jacket arrangements for maintaining temperature.

Working

The heating medium (steam, hot or cold water) is passed through the outer tube. The viscous fluid to be heated is passed through the inner tube at low velocity. Heat transfer takes place through the circulated surface by conduction and convection. The portion of liquid adjacent to the inner surface of the inner tube is stagnant. The shaft is allowed to rotate at a certain speed and scrape the inside surface of the inner tube. Any liquid that was previously on this surface is scraped and replaced by another liquid at that temperature. This permits the effective transfer of heat, but in an unsteady state condition.

Uses: Scraped-surface exchangers are particularly suitable for heat transfer (cooling) in crystallization. Heat transfer is effective even with severe fouling, solvent extraction, and high-velocity fluids. This is possible because of the spring-loaded scraped blade mechanism. These are used in the production of food products and other heat-sensitive liquids (using a high vacuum). It is used in paraffin wax plants.

Make sure you also check our other amazing Article on: Double Pipe Heat Exchanger