Table of Contents

Principle of the vacuum dryer

In a vacuum dryer, the material is dried by the application of a vacuum. When the vacuum is created, the pressure is lowered so that water boils at a lower temperature. Hence, water evaporates faster. The heat transfer becomes efficient, i.e., the rate of drying enhances substantially.

Construction of the vacuum dryer

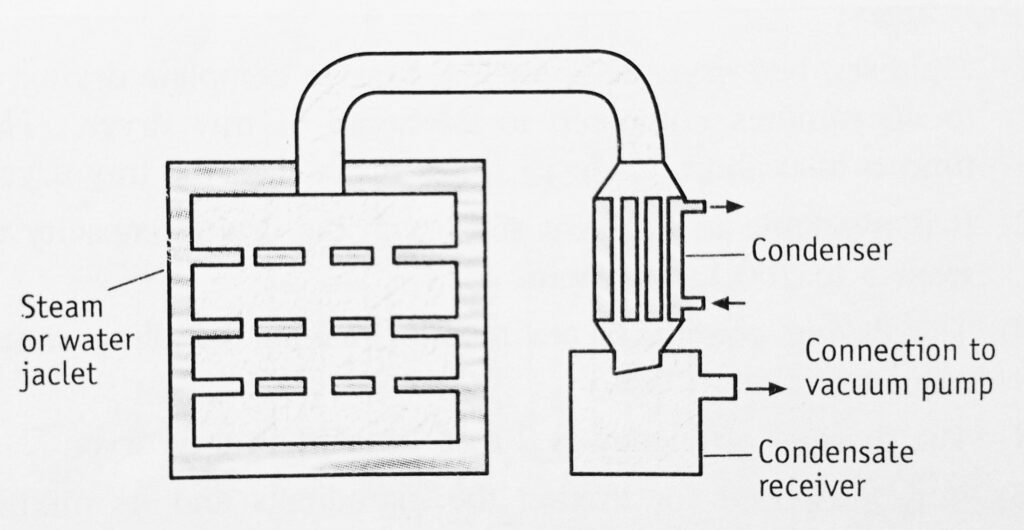

The construction of a vacuum dryer is shown in Figure 1.1. It is made of a cast-iron heavy-jacketed vessel. It is so strong that it can withstand a high vacuum within the oven and steam in the jacket. The enclosed space (approximately 1.5-metre cube) is divided into a number of portions by means of 20 hollow shelves, which are part of the jacket. These shelves provide a larger surface area (about 45 to 50 metres square) for the conduction of heat. Over the shelves, metal trays are placed for keeping the material. The oven door can be locked tightly to give an airtight seal. The oven is connected to a vacuum pump by placing a condenser in between.

Working on vacuum dryer

The material to be dried is spread on trays. The trays are placed on the shelves. The door is closed firmly. Pressure is decreased up to 30 to 60 kilopascals by means of a vacuum pump. The door is closed firmly. Steam or hot air is supplied into the hollow space of the jacket and shelves. Heat transfer by conduction takes place. In this vacuum, evaporation of water from the material takes place at 25-30 °C, on account of the lowering of the boiling point. Water vapour passes into the condenser where condensation takes place. At the end of the drying, the vacuum line is disconnected. The material is collected from the trays.

Pharmaceutical uses of vacuum dryer

A vacuum dryer can be used for drying the following:

- Heat sensitive materials undergo decomposition.

- Dusty and hygroscopic materials.

- Drugs containing toxic solvents. These can be separated into closed containers.

- Feed containing valuable solvents. These are recovered by condensation.

- Drugs are required as porous end products.

- Friable dry extracts.

Advantages:

- A vacuum dryer provides a large surface area for heat transfer.

- Handling the material, trays and equipment is easy.

- It is easy for switching over to the next materials.

- Hot water of desired temperatures can be supplied.

- Electrically heated hollow shelves can be used.

Disadvantages:

- In a dryer, heat transfer coefficients are low.

- It has a limited capacity and is used for batch processes.

- It is more expensive than a tray dryer. Labour and running costs are also high.

- Sometimes, there is a danger of overheating as the material is in contact with a steam-heated surface for a longer period.

Make sure you also check our other amazing Article on : Fluidised Bed Dryer