Table of Contents

Principle of the vertical tube evaporator

In a standard vertical tube evaporator, the liquid is passed through the vertical tubes and the steam is supplied from outside the tubes. Heat transfer takes place through the tubes and the liquid inside the tubes gets heated. The solvent evaporates and the vapour escapes from the top. The concentrated liquid is collected from the bottom.

Construction of the vertical tube evaporator

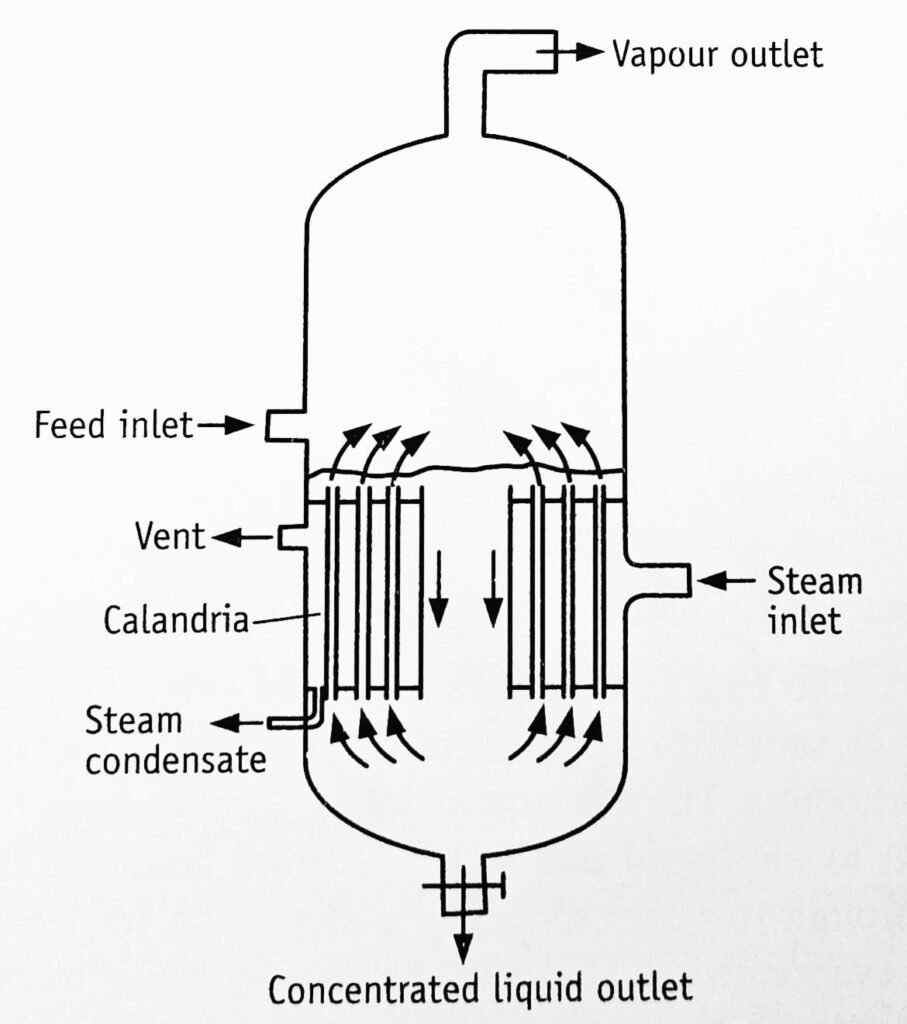

The construction of a standard vertical tube evaporator is shown in Figure 1.1. It consists of a large cylindrical body made up of cast iron with a dome-shaped top and bottom (Figure 1.1). Inside the body, calandria is fitted at the bottom. Calandria consists of a number of vertical tubes, whose diameter ranges from 0.05 to 0.075 metres and lengths of 1-2 metres. About 100 such tubes are fitted in a body measuring 2.5 metres or more in diameter. Inlets are provided for steam and feed. Outlets are provided for vapour, concentrated product, non-condensed gases and condensate.

Working on vertical tube evaporator

Steam is introduced outside the tubes. The condensate is passed through the corresponding outlet and non-condensed gases escape through the vent. The feed is introduced in such a way as to maintain the liquid level slightly above the top of the tubes. The liquid inside the tubes is heated by the steam and begins to boil. As the liquid boils, it spouts up through the tubes and returns through the central down-take. It sets up a circulation of hot liquid, which enhances the rate of heat transfer. The vapour escapes through the top outlet. Steam is supplied until the required concentration of the product is obtained. Finally, the product can be withdrawn from the bottom outlet.

Uses: Vertical tube evaporator is used in the manufacture of Cascara extract, sugar, salt, and caustic soda.

Advantages

- In a vertical tube evaporator, tubes increase the heating surface nearly 10 to 15 times when compared with a steam jacketed kettle.

- Vigorous circulation enhances the rate of heat transfer.

- It can be connected to a condenser and receiver, which further increases the rate of evaporation. Such attachment is also suitable for volatile solvents.

- A number of units can be joined to obtain a more efficient effect (multiple effect evaporators are later).

Disadvantages:

The liquid is maintained above the level of the calandria. Hence, the upper layers of the liquid need a long time for getting heated. This problem can be minimised by removing concentrated liquid slowly at the bottom.

The evaporator is complicated, hence, installation cost increases. Cleaning and maintenance are difficult when compared with a steam jacketed kettle.

During operation, the pressure inside the evaporator increases. In large evaporators, where the liquid depth may be of the order of 2.0 metres, the pressure increases to 25.0 kilopascals, leading to elevation of the boiling point by 5 or 6°C. This reduces the effective temperature gradient and may affect heat-sensitive materials.

Variants: Short tube vertical evaporator with propeller: In a short tube vertical evaporator, circulation depends completely on boiling. Steam is supplied into the calandria to induce boiling. When the steam supply is stopped, automatically boiling stops. As a result, the particles (if any) settle down. These particles act as nuclei that grow as crystals. Therefore, this evaporator is sometimes used as a crystallizing evaporator. If such crystallization is undesirable, the problem can be avoided by installing a propeller in the central portion close to the bottom. By increasing the revolutions per minute of the propeller, the capacity of the evaporator can be doubled.

Uses: Since mild steel or cast iron is used, the evaporator suits well for clear liquids and crystallizing solutions. Non-corrosive liquids and mild scaling solutions can also be handled.

Advantages: Heat transfer coefficients are high due to high-temperature gradient values. It requires a low headroom. Cleaning and maintenance are easy. It is relatively inexpensive.

Disadvantages: Heat transfer is poor at low At values. It requires high floor space and is more in Relatively more liquid is retained. The rate of heat transfer further decreases due to the high viscosity of liquids. Since the body is large, mild steel or cast iron is used for its construction to make it less expensive.

Basket type evaporator: The basket type of evaporator has a conical bottom and sometimes a flat bottom. In this type, boiling is quite violent. Hence, the spouting of the liquid leads to entrainment. This problem can be avoided by placing a deflector over the tubes. In this case, the down-take is annular instead of being central. The advantage of this type is that an entire heating element is a single unit. The complete unit can be removed for repairs. In addition, the deflector prevents entrainment losses completely.

Make sure you also check our other amazing Article on : Horizontal Tube Evaporator